CUTMASTER 60i

Manual 0-5436 OPERATION

4T-11

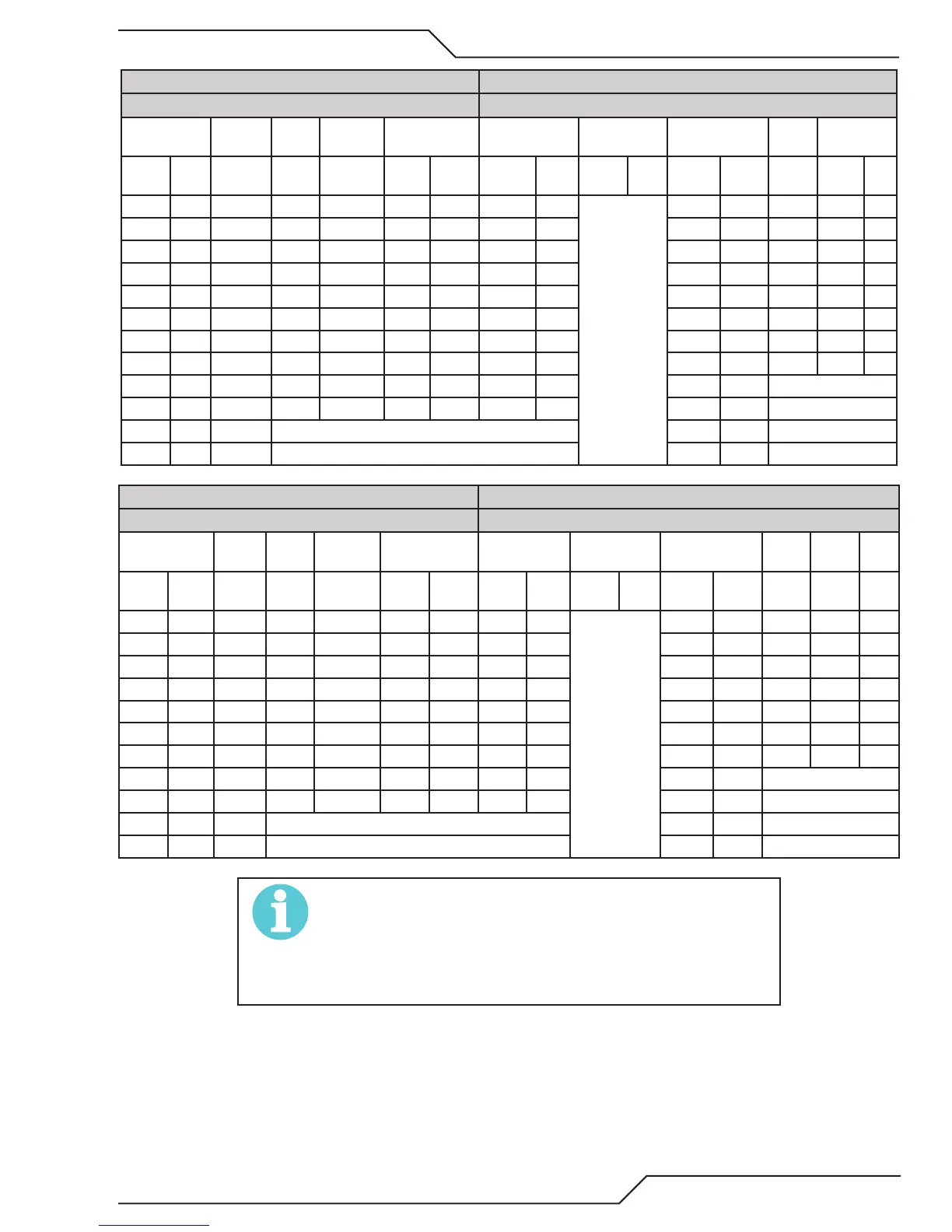

CutMaster® 60i With Exposed Tip Type Material: Stainless Steel

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per

Minute)

Standoff Plasma Gas

Pressure*

Flow (SCFH) Pierce Pierce

Height

Inches mm (Cat. No.) Volts

(VDC)

(Amps) Inches Meters Inches mm psi bar Plasma Total** Delay

(Sec)

Inches mm

0.06 1.5 9-8210 119 60 350 8.91 0.19 4.8

Set to the

central

region on

the pressure

dial. This is

illuminated

green when

selected.

90 245 0.00 0.20 5.1

0.075 1.9 9-8210 116 60 300 7.64 0.19 4.8 90 245 0.10 0.20 5.1

0.120 3.0 9-8210 123 60 150 3.82 0.19 4.8 90 245 0.10 0.20 5.1

0.135 3.4 9-8210 118 60 125 3.18 0.19 4.8 90 245 0.10 0.20 5.1

0.188 4.8 9-8210 122 60 90 2.29 0.19 4.8 90 245 0.20 0.20 5.1

0.250 6.4 9-8210 120 60 65 1.65 0.19 4.8 90 245 0.30 0.20 5.1

0.375 9.5 9-8210 130 60 30 0.76 0.19 4.8 90 245 0.50 0.20 5.1

0.500 12.7 9-8210 132 60 21 0.53 0.19 4.8 90 245 0.75 0.20 5.1

0.625 15.9 9-8210 130 60 15 0.38 0.19 4.8 90 245 Rolling Pierce

0.750 19.1 9-8210 142 60 12 0.31 0.25 6.4 90 245 Rolling Pierce

1.000 25.4 9-8210 NR, manual cutting only 90 245 Rolling Pierce

1.250 31.8 9-8210 NR, manual cutting only 90 245 NR

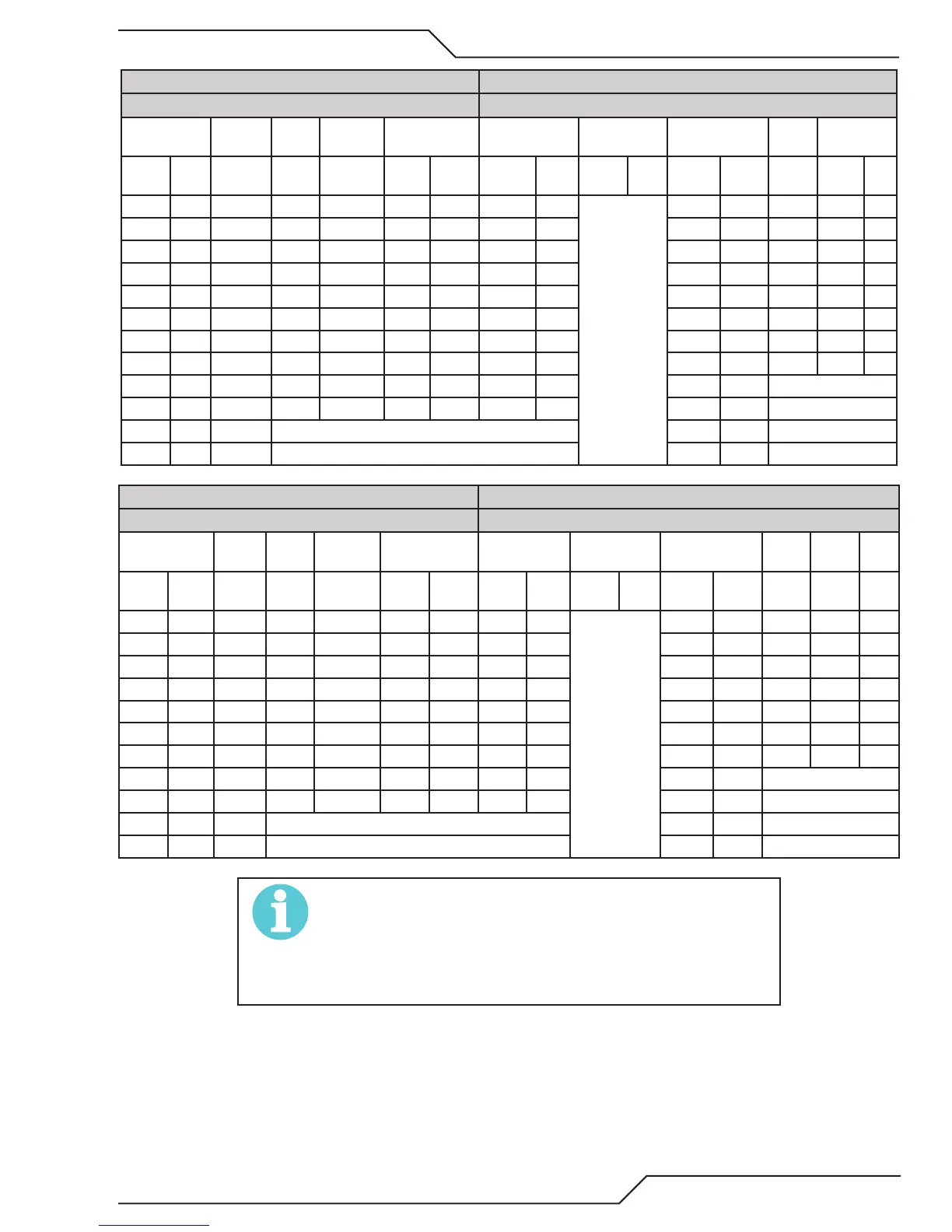

CutMaster® 60i With Exposed Tip Type Material: Aluminum

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per

Minute)

Standoff Plasma Gas

Pressure*

Flow (SCFH) Pierce Pierce

Height

Inches mm (Cat.

No.)

Volts

(VDC)

(Amps) Inches Meters Inches mm psi bar Plasma Total** Delay

(Sec)

Inches mm

0.060 1.5 9-8210 110 60 440 11.18 0.25 6.4 Set to the

central

region on

the pressure

dial. This is

illuminated

green when

selected.

90 245 0.00 0.25 6.4

0.075 1.9 9-8210 110 60 440 11.18 0.25 6.4 90 245 0.10 0.25 6.4

0.120 3.0 9-8210 116 60 250 6.35 0.25 6.4 90 245 0.10 0.25 6.4

0.188 3.4 9-8210 116 60 170 4.32 0.25 6.4 90 245 0.20 0.25 6.4

0.250 6.4 9-8210 132 60 85 2.16 0.25 6.4 90 245 0.30 0.25 6.4

0.375 9.5 9-8210 140 60 45 1.14 0.25 6.4 90 245 0.50 0.25 6.4

0.500 12.7 9-8210 143 60 30 0.76 0.25 6.4 90 245 0.80 0.25 6.4

0.625 15.9 9-8210 145 60 20 0.51 0.25 6.4 90 245 Rolling Pierce

0.750 19.1 9-8210 145 60 18 0.46 0.25 6.4 90 245 Rolling Pierce

1.000 25.4 9-8210 NR, manual cutting only 90 245 Rolling Pierce

1.250 31.8 9-8210 NR, manual cutting only 90 245 NR

NOTE!

* If the proper torch and lead length are selected using the 'gas pres-

sure selector' knob and the central region (green) on the pressure dial

is selected, the pressure is optimized for the selected cutting amperage.

Refer to Section 4 of the Operating Manual, "Set Operating Pressure".

** Total flow rate includes plasma and secondary gas flow.

Loading...

Loading...