Manual 0-2577 11 OPERATION

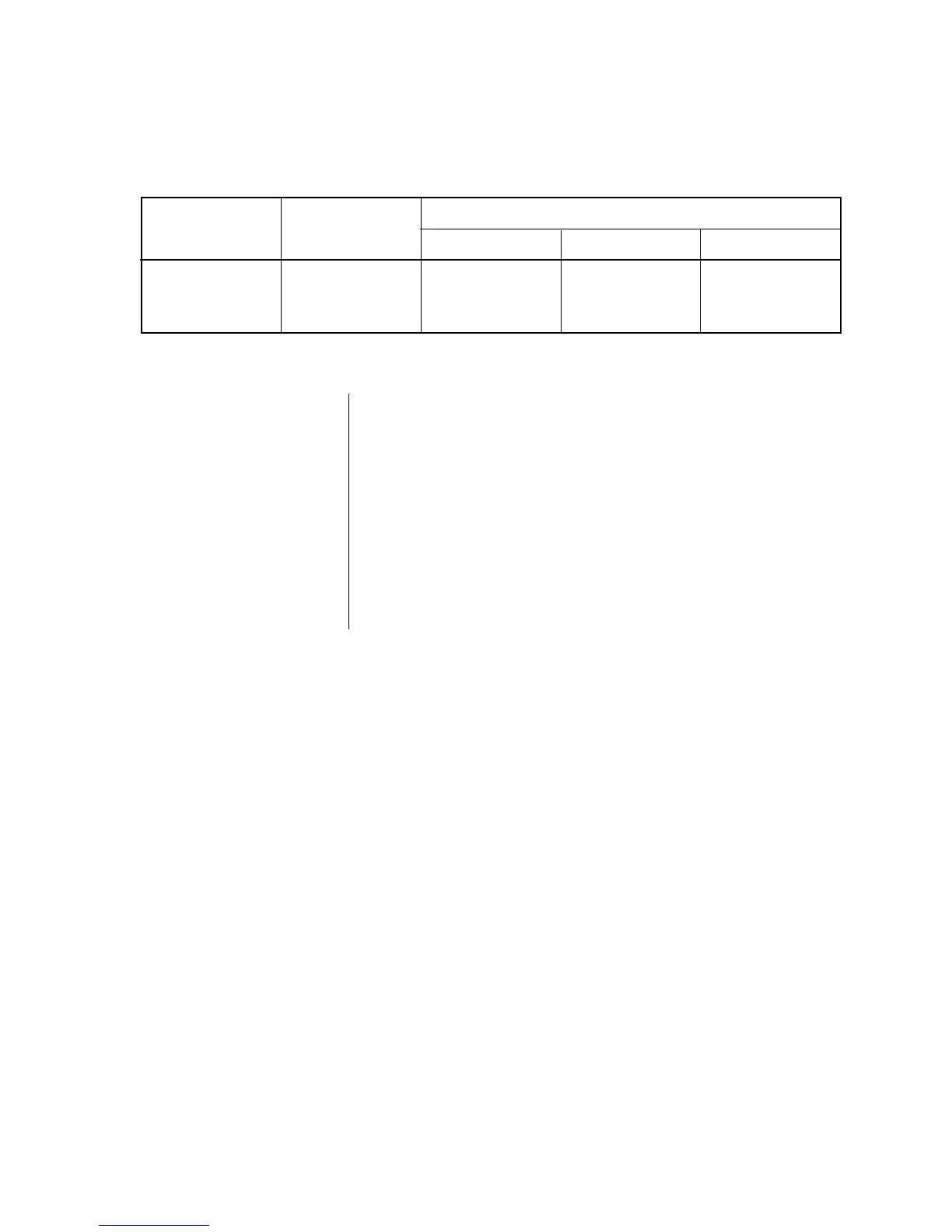

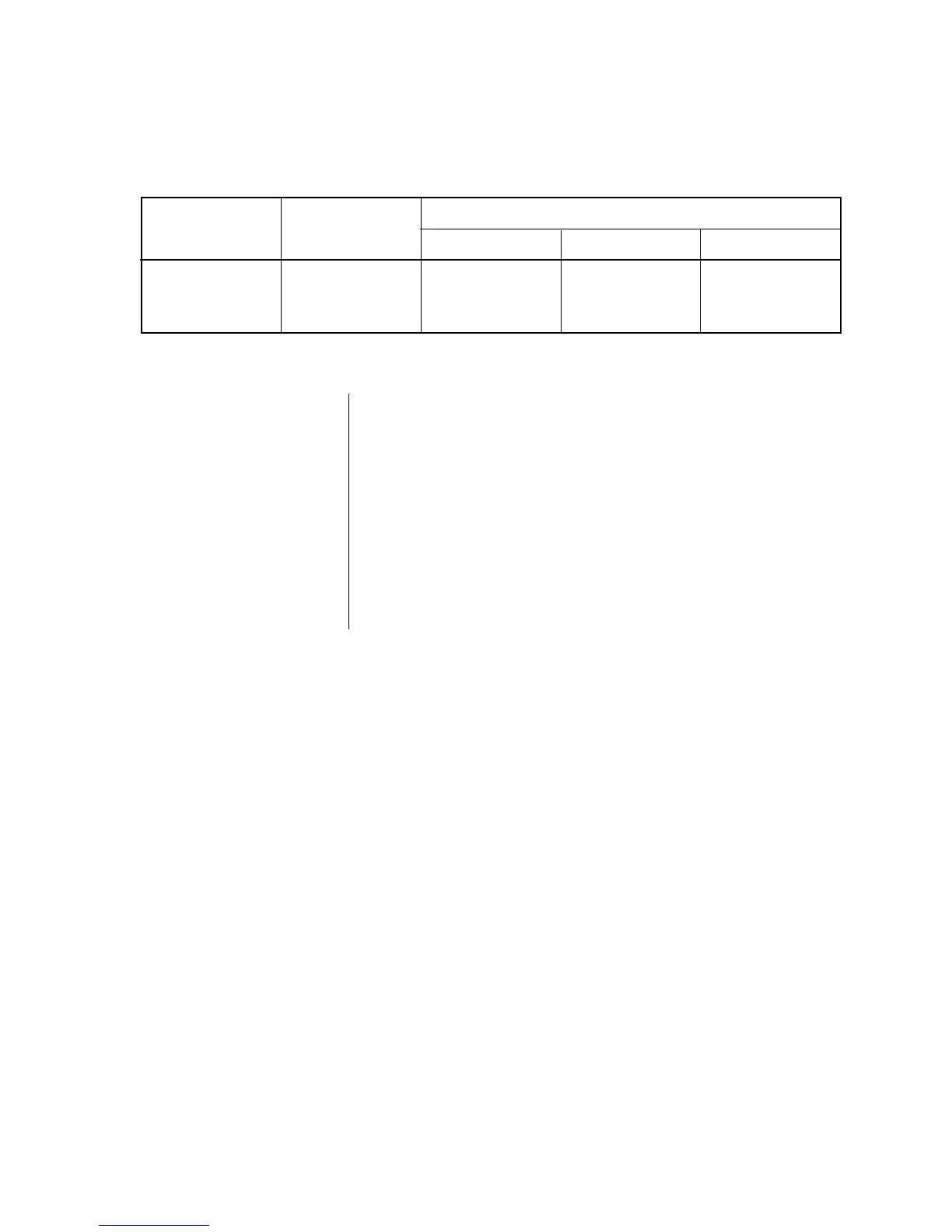

GAS

Air

Nitrogen

Stainless Steel

Good - Excellent

Good

TYPE OF MATERIAL

Carbon Steel

Good - Excellent

Good

Aluminum

Good - Excellent

Good

MATERIAL

THICKNESS

Gage to 1/4 in.

(Aluminum to 3/16 in.)

Table 3-A Cut Quality on Various Materials and Material Thicknesses

Excellent - Minimum bevel (0 - 4°), minimum kerf (2 x tip orifice

diameter), little or no dross, smooth cut surface.

Good - Slight bevel (0 - 10°), slightly wider kerf (2-1/2 x tip

orifice diameter), some dross (easily removed), medium-smooth

cut surface, slight top edge rounding.

Fair - Excessive bevel (over 10°), wide kerf (over 2-1/2 x tip

orifice diameter), medium to heavy dross, rough cut surface, top

edge rounding.

Cut quality depends heavily on set-up and parameters such as

torch standoff, alignment with the workpiece, cutting speed, gas

pressures, and operator ability.

Description of Cut

Characteristics

NOTE

Loading...

Loading...