Manual 0-2577 15 OPERATION

3.7 RECOMMENDED CUTTING SPEEDS

Cutting speed depends on material, thickness, and the operator’s

ability to accurately follow the desired cut line. The following

factors may have an impact on system performance:

• Torch parts wear

• Air quality

• Line voltage fluctuations

• Torch standoff height

• Proper work cable connection

This information represents realistic expectations using recom-

mended practices and well-maintained systems. Actual speeds

may vary up to 50% from those shown.

Recommended

Cutting Speeds

NOTE

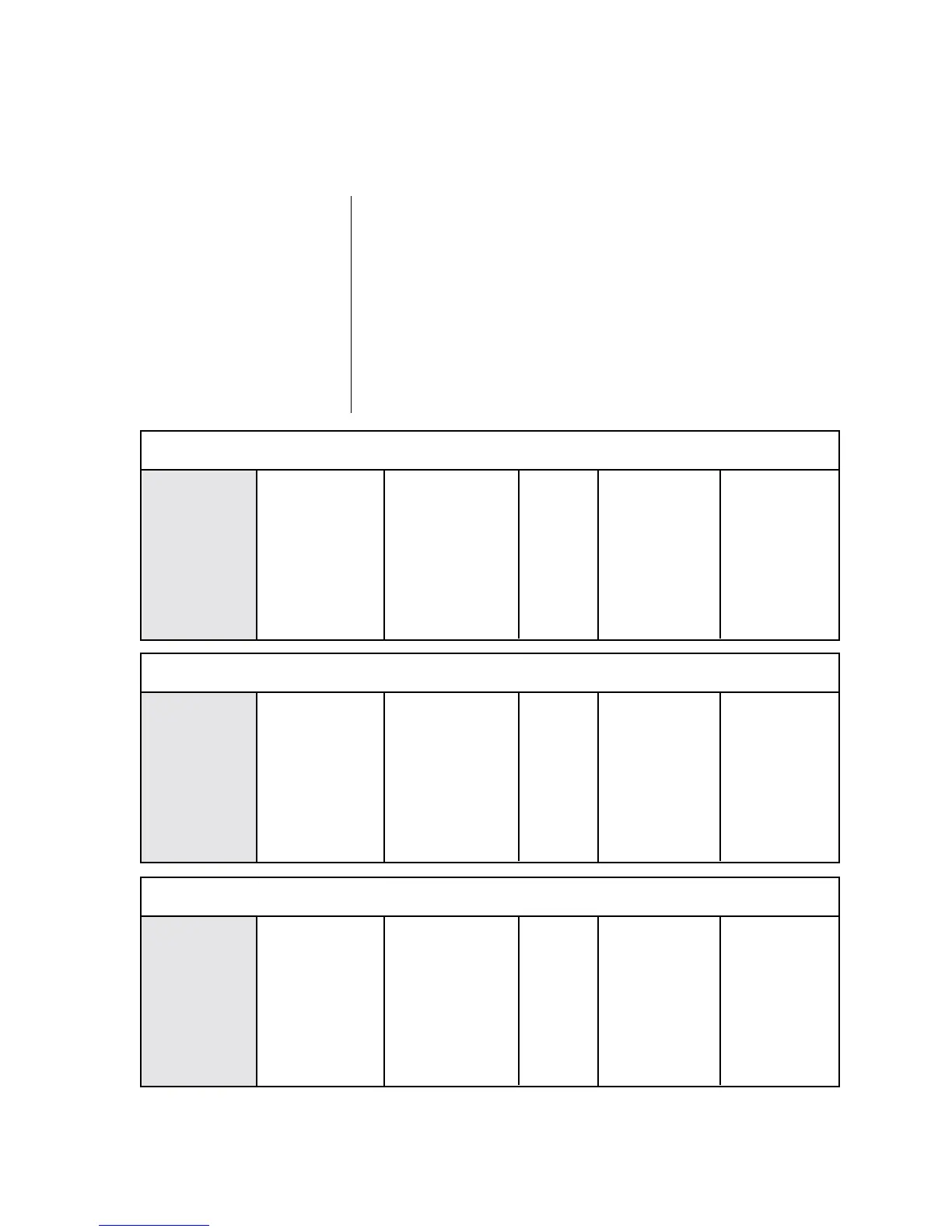

Tables 3-D Recommended Cutting Speeds

Material Thickness Cut Speed (IPM) Amps Gas / Pressure Stand Off

MILD STEEL 26 gauge 250 20 Air / 50 psi Drag - 1/8"

20 gauge 125 20 Air / 50 psi Drag - 1/8"

1/16" (1.6 mm) 85 20 Air / 50 psi Drag - 1/8"

1/8" (3.2 mm) 25 20 Air / 50 psi Drag - 1/8"

3/16" (4.8 mm) 15 20 Air / 50 psi Drag - 1/16"

1/4" (6.4 mm) 8 20 Air / 50 psi Drag - 1/16"

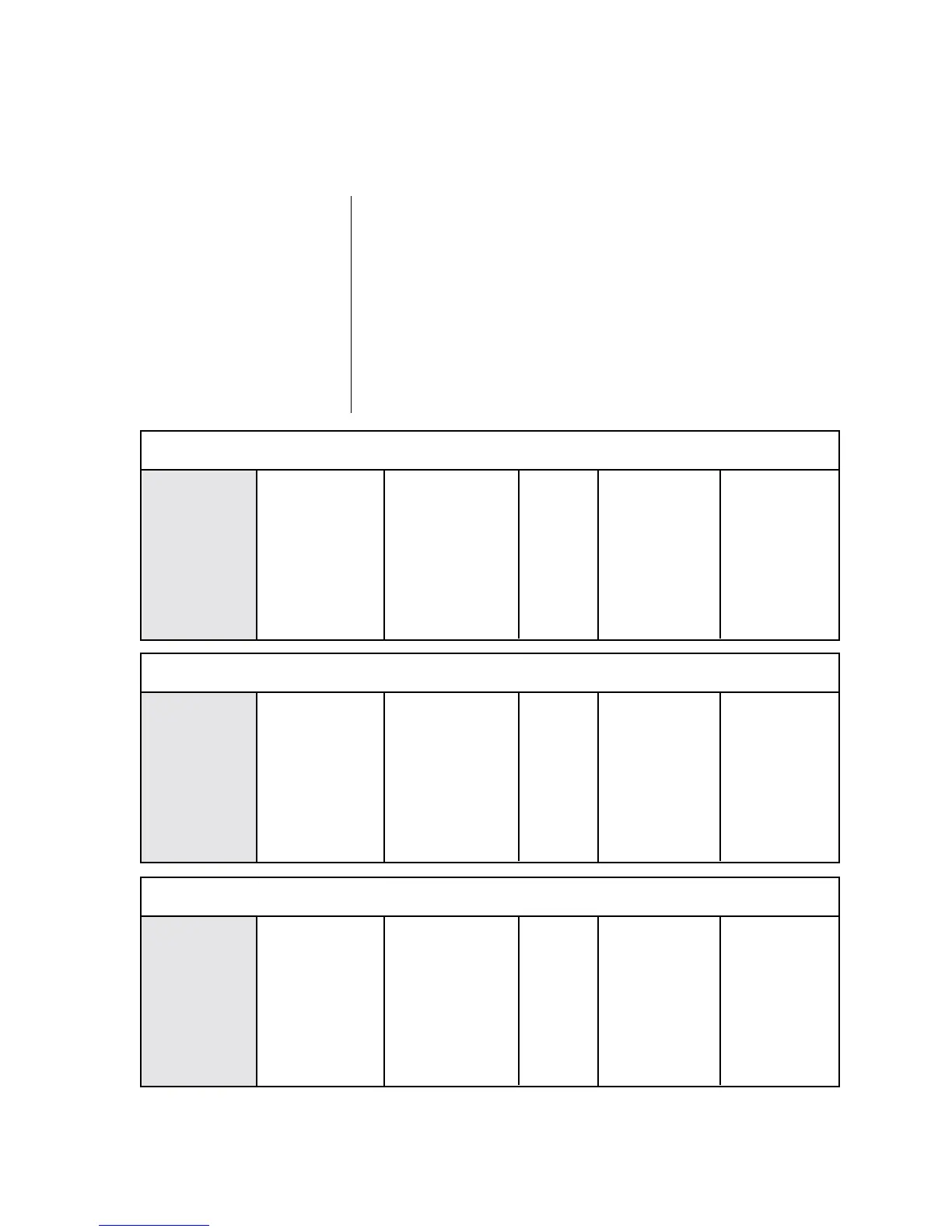

Material Thickness Cut Speed (IPM) Amps Gas / Pressure Stand Off

STAINLESS 20 gauge 125 20 Air / 50 psi Drag - 1/8"

STEEL 1/16" (1.6 mm) 40 20 Air / 50 psi Drag - 1/8"

1/8" (3.2 mm) 25 20 Air / 50 psi Drag - 1/8"

3/16" (4.8 mm) 10 20 Air / 50 psi Drag - 1/16"

Material Thickness Cut Speed (IPM) Amps Gas / Pressure Stand Off

GALVANIZED 24 gauge 100 20 Air / 50 psi Drag - 1/8"

STEEL 20 gauge 75 20 Air / 50 psi Drag - 1/8"

18 gauge 65 20 Air / 50 psi Drag - 1/8"

1/16" (1.6 mm) 45 20 Air / 50 psi Drag - 1/8"

5/64" (2.0 mm) 30 20 Air / 50 psi Drag - 1/8"

Loading...

Loading...