SERVICE 5-2 Manual 0-2962

B. O-Ring Lubrication

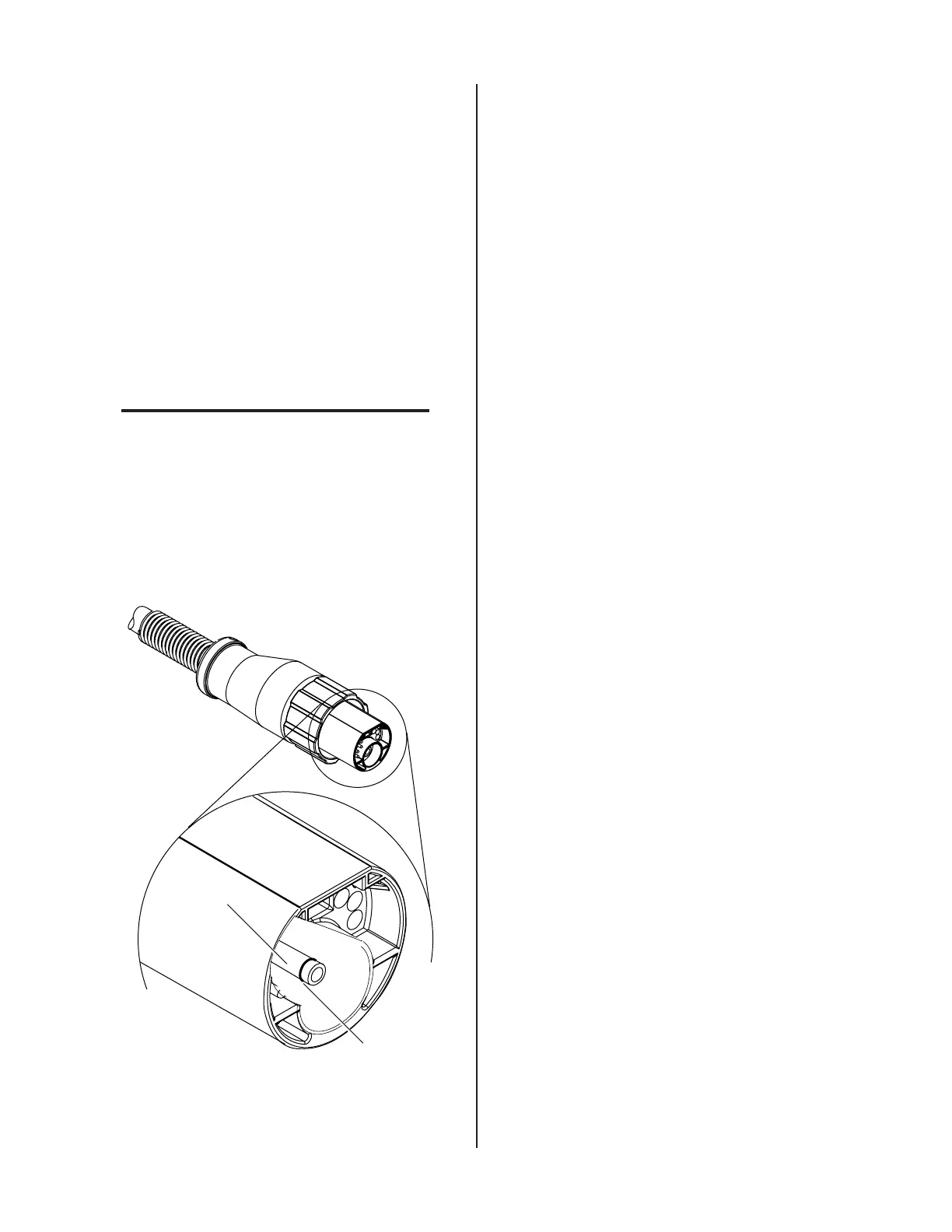

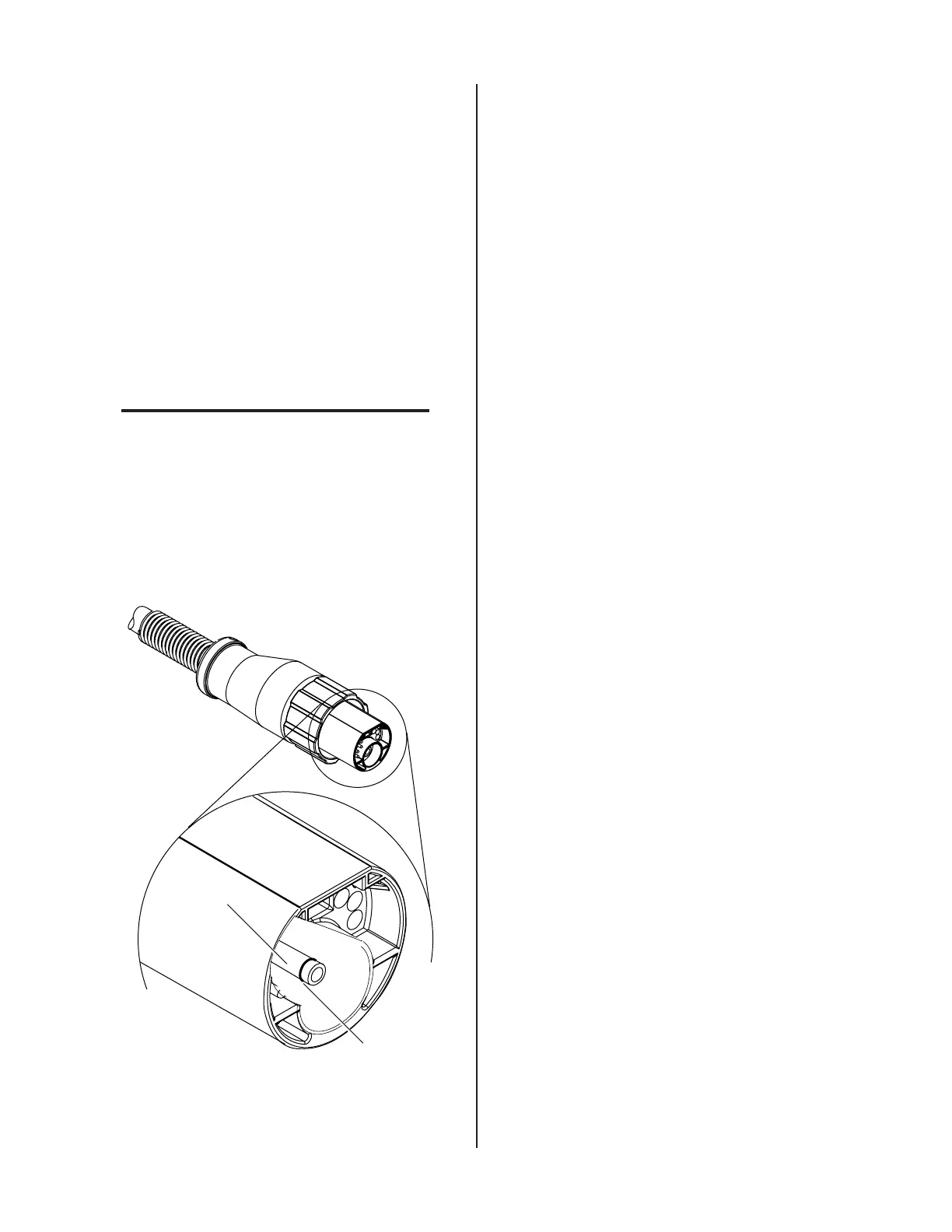

This section applies only to torches withATC connec-

tors.

An o-ring on the Torch ATC Male Connector requires

lubrication on a regular basis, depending on how fre-

quently the torch is disconnected and re-connected.

This will allow the o-ring to remain pliable and pro-

vide a proper seal. The o-ring will dry out, becom-

ing hard and cracked, if the o-ring lubricant is not

used on a regular basis. This can lead to potential

performance problems.

It is recommended to apply a very light film of o-

ring lubricant (Catalog # 8-4025) to the o-ring on a

weekly basis.

NOTE

DO NOT use other lubricants or grease, they may

not be designed to operate within high tempera-

tures or may contain “unknown elements” that

may react with the atmosphere. This reaction can

leave contaminants inside the torch. Either of these

conditions can lead to inconsistent performance or

poor parts life.

ATC Male Connector

Art #A-03791

Gas Fitting

O-Ring

5.03 Common Operating Faults

The following lists the more common cutting faults and

possible causes:

1. Insufficient Penetration

a. Cutting speed too fast

b. Torch tilted too much

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. Non - Genuine Thermal Dynamics Parts

2. Main Arc Extinguishes

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. Non - Genuine Thermal Dynamics Parts

3. Excessive Dross Formation

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

e. Non - Genuine Thermal Dynamics Parts

4. Short Torch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Air flow too low (incorrect pressure)

e. Improperly assembled torch

f. Non - Genuine Thermal Dynamics Parts

Loading...

Loading...