5-11

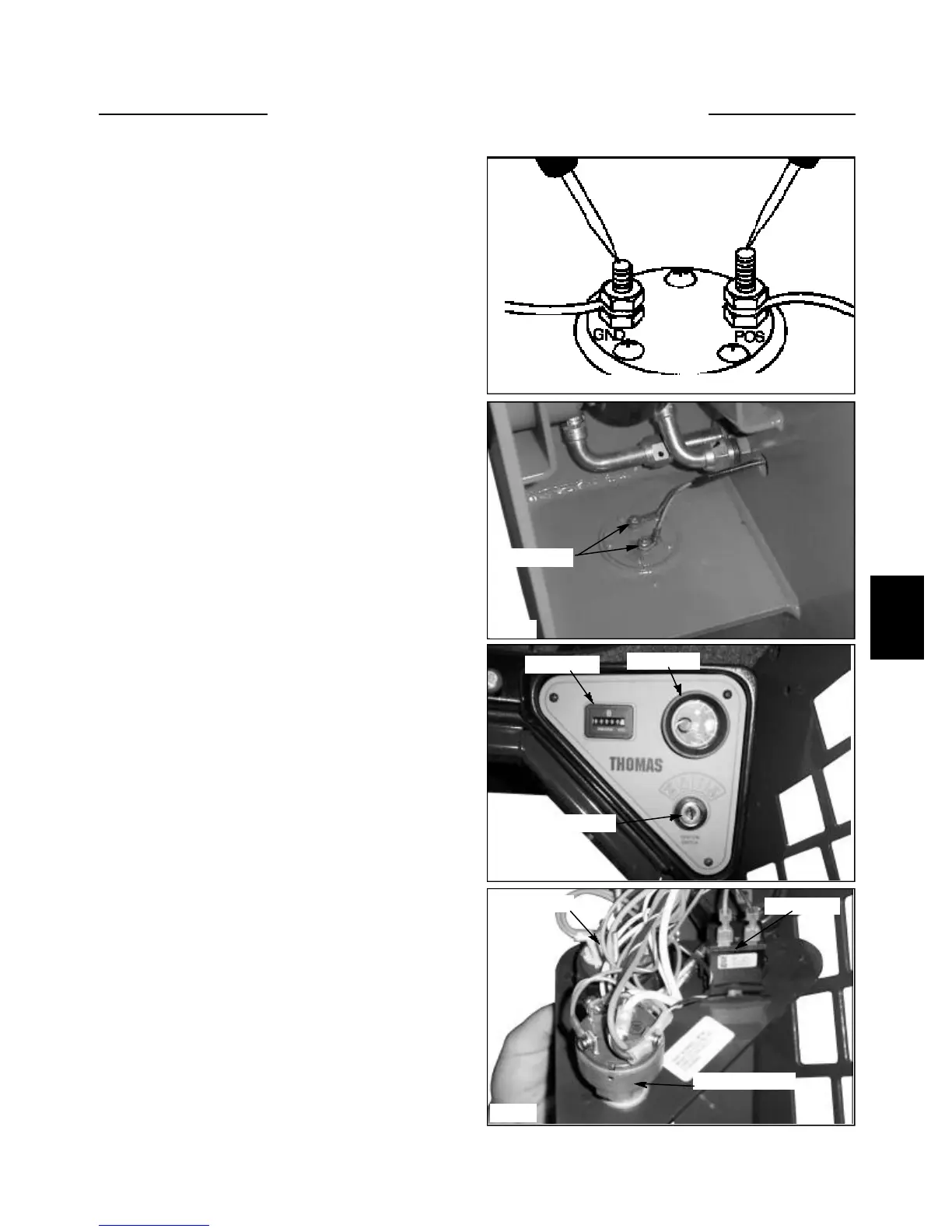

1 With the ignition switch off, connect an ohmmeter

between the positive and negative terminals of the fuel

sending unit. (fig. C306)

2 An ohmmeter reading of 50 to 500 is normal. A read-

ing higher or lower means a faulty sender and will need

replaced.

Testing the Fuel Sender

C306

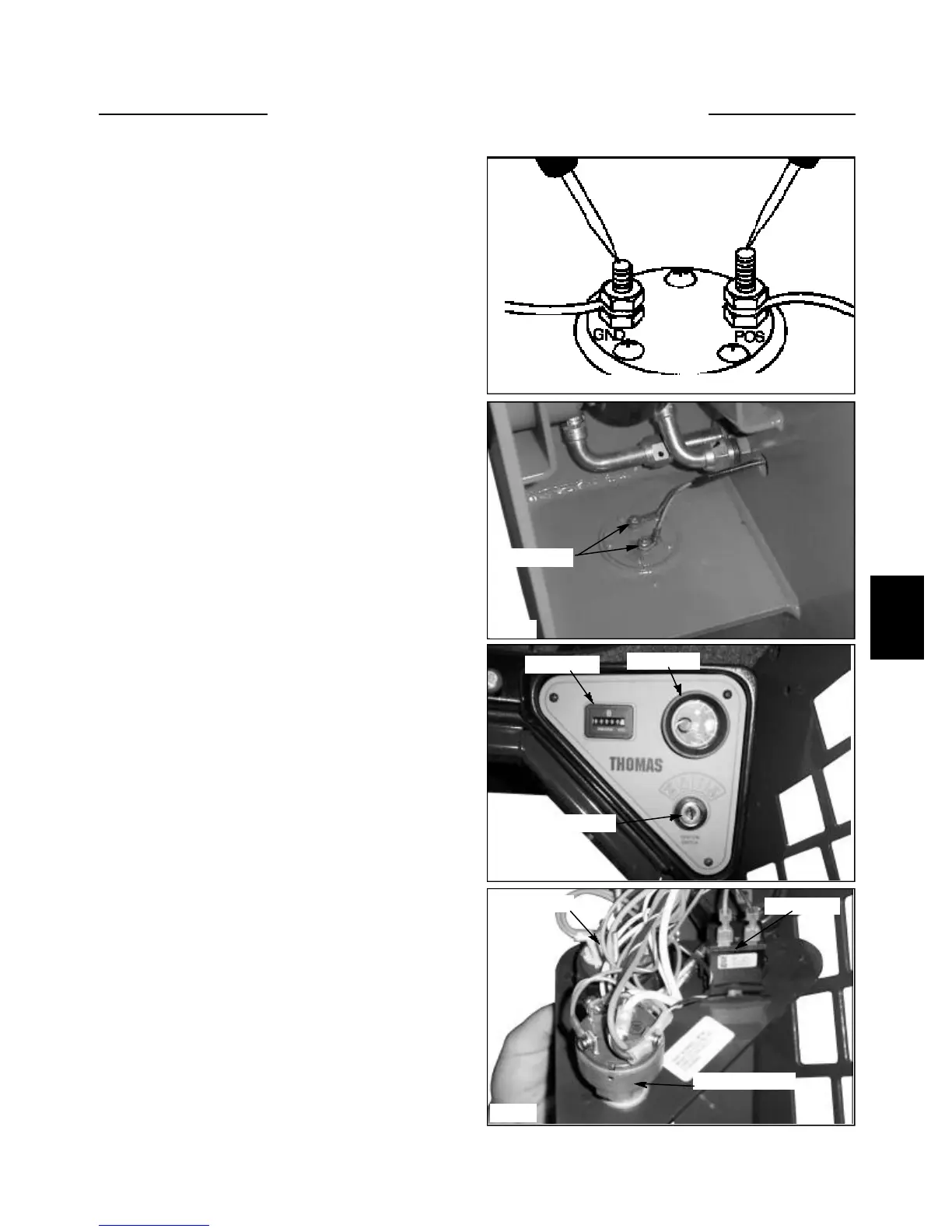

C3582

Replacement

1 Remove any attachment, raise the boom arms and

engage the boom support pins. Shut off the engine and

engage the parking brake.

2 Remove the 2 wires connected to the fuel sending

unit. The fuel sender is located just below the lift cylin-

der, right hand side, on the fuel tank.

3 Remove the 5 screws retaining the sender to the fuel

tank.

4 Remove the sending unit and discard the gasket.

5 Install a new sending unit and gasket. Use gasket

sealant on both sides of the gasket.

6 Use thread sealant on the screws and torque the

screws to 20 inch / lbs. (fig. C3582)

7 Connect the sender wires taking care not to over

tighten the nuts and stripping the studs. Green wire is

ground.

Testing the Hour Meter

The hour meter records the number of engine operating

hours.

To check the hour meter, remove the 3 screws retaining

the right hand dash panel to the dash pod. (fig. C3580,

C3581)

Using a 12 volt test meter, connect the positive lead to the

positive terminal of the hour meter and the ground lead of

the tester to a good ground. Turn the ignition switch to

the “RUN” position.

A reading of 12 volts means the hour meter is operating

properly.

No voltage reading means there could be a problem in the

wire running from the “ACC” terminal on the ignition

switch to the positive side of the hour meter or a defec-

tive ignition switch.

C3581

Ignition switch

Fuel gauge

Hour meter

C3580

Ignition switch

Fuel gauge

Hour meter

INSTRUMENTATION 5.3

Fuel gauge

Loading...

Loading...