MAINTENANCE 7.7

Fan Belt Adjustment

The fan (alternator) drive belt should be checked daily for

tension and wear. The drive belt should be replaced

promptly when fraying of the belt cords or cracks in the

rubber are observed. Failure to replace the drive belt

could lead to slippage or complete failure, causing the

engine to over heat and lead to extensive repairs.

To Adjust the Fan Belt:

1 Park the loader on a level surface, lower the boom

arms, engage the parking brake and shut off the engine.

2 Access the engine compartment by opening the rear

door and lifting the engine cover. (fig. C3624)

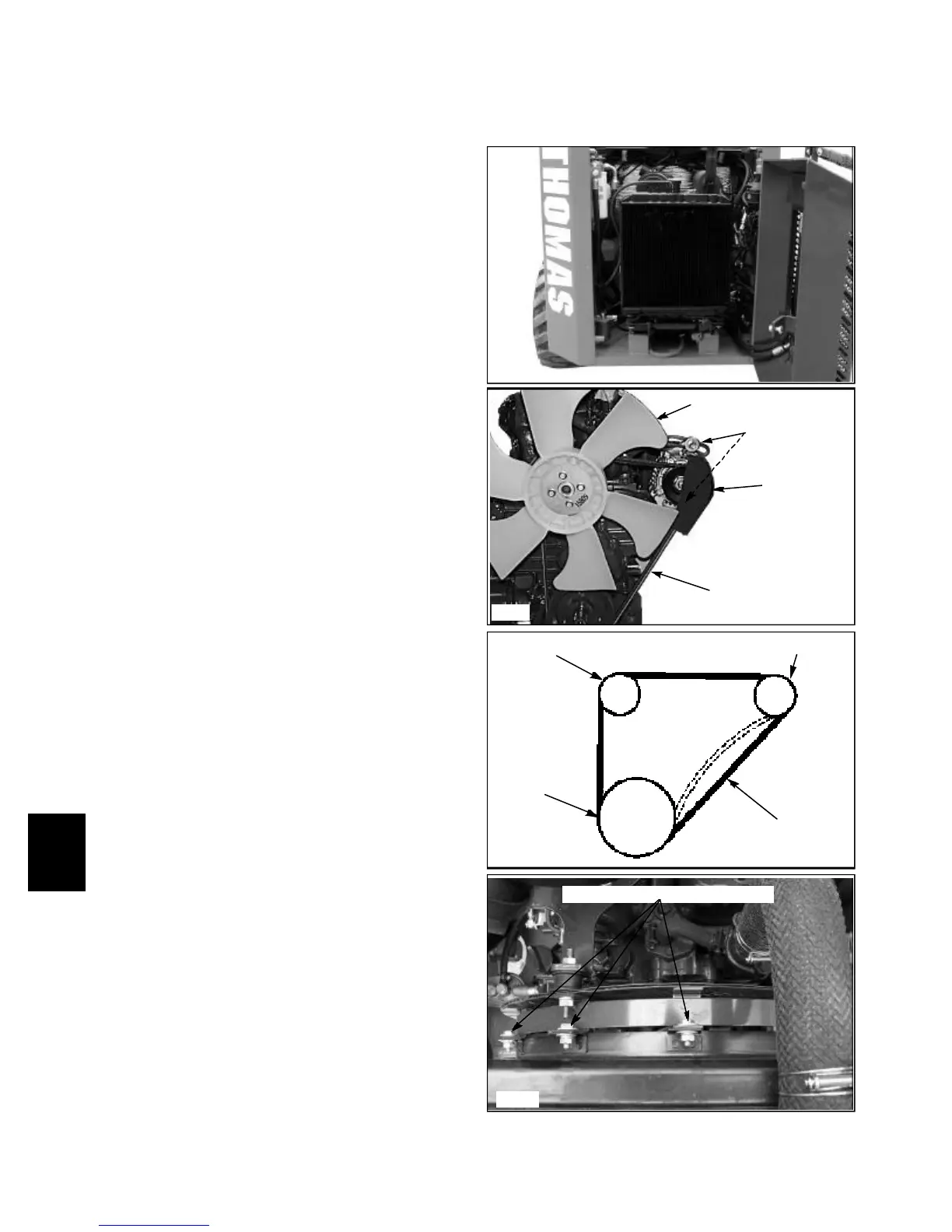

3 Locate the drive belt. Fig. C834 shows the drive belt

without the radiator obstructing the view.

4 Check the drive belt tension midway between the

alternator and crankshaft drive pulley. (fig. C3866)

Correct tension is 10 ~ 12mm deflection @ 98 newtons

force. (3 / 8 ~ 1 / 2’’ deflection @ 22 lbs force).

Fan Belt Replacement:

1 Loosen the 2 bolts on the alternator and allow the

belt tension to loosen off. (fig. C834)

2 Remove the bolts retaining the fan guard to the radia-

tor shroud. (fig.C3627)

3 Pull the drive belt off the alternator pulley, crankshaft

pulley and remove from around the fan.

4 Replace in reverse order and adjust belt tension as

described above.

7-10

C3624

C3627

C3866

C834

Drive belt

Fan pulley Alternator pulley

Measure belt

tension here

Cooling fan

Alternator bolts

Crankshaft

pulley

Radiator shroud / fan guard bolts

Guard

Loading...

Loading...