Cooling System

Daily Checks:

The loader is equipped with a liquid cooled diesel engine

that requires daily coolant level checks and radiator ser-

vice if necessary.

The cooling system should always be checked when the

engine is cool.

Park the loader on a level surface, lower the boom arms,

engage the parking brake and shut off the engine.

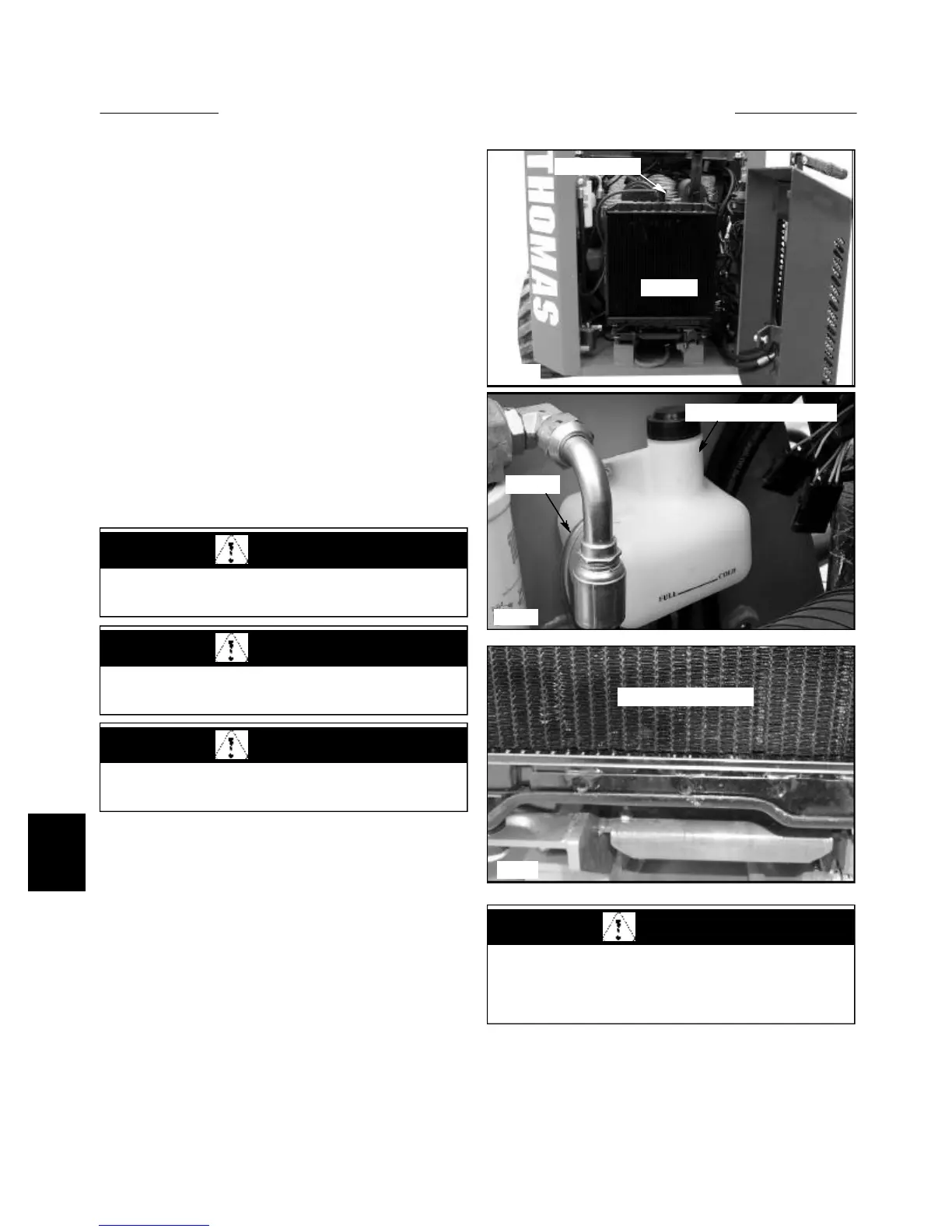

1 Access the engine compartment by opening the rear

door and lifting the engine compartment cover.

2 Visually inspect the radiator cooling fins for dirt or

debris build up that may be blocking air flow through the

radiator. (fig. C3626) Blow any dirt or debris out with

compressed air and / or water. Do not excede 40 psi (2.7

Kg / cm

2

) Any bent cooling fins should be carefully

straightened to prevent core damage.

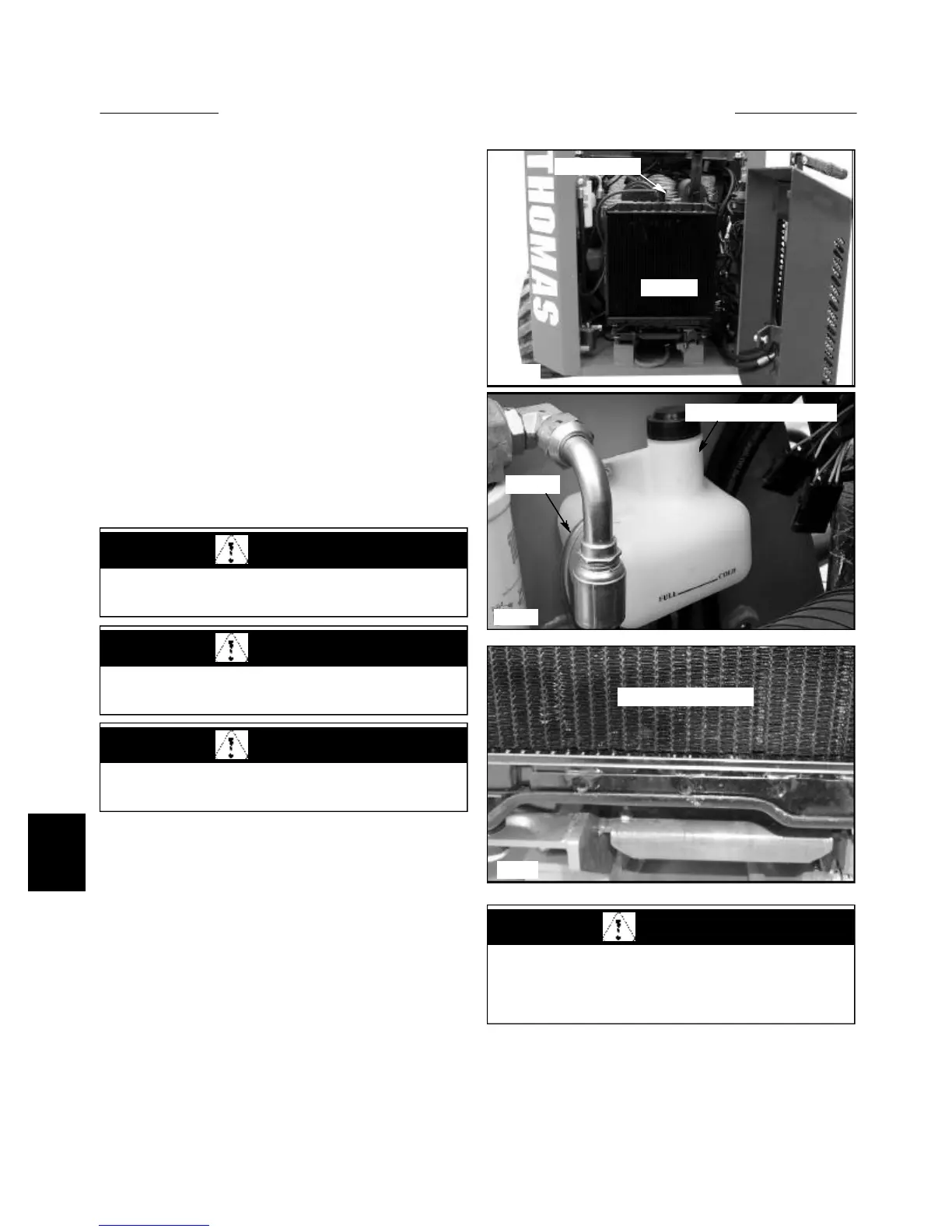

3 Visually inspect the coolant overflow tank for the

proper coolant level marked on the tank. (fig. C3625)

Add a 50 / 50 mixture of ethylene glycol and water as

required.

4 Remove the radiator cap to verify the coolant level in

the radiator. If the coolant level is below the upper part of

the radiator tank, and the coolant bottle is still full, then

either the radiator cap is defective or there is a coolant

leak in the cooling system. Perform a pressure test of the

cooling system.

Testing the Cooling System:

1 Ensure the radiator is full of coolant.

2 Start the engine operate until warm, NOT HOT!

3 Shut off the engine and carefully remove the radiator

cap. Use extreme caution.

7-8

C3624

C3626

C3625

Radiator cap

Radiator

Coolant over flow tank

Fill line

Radiator cooling fins

ENGINE MAINTENANCE 7.1

WARNING

To prevent eye injury, wear safety goggles when

cleaning with compressed air

CAUTION

To prevent radiator fin damage, do not use air pres-

sure higher than 40 psi (2.7 kg / cm

2

)

WARNING

Do not remove the radiator cap when the engine is

hot.

WARNING

Always use a pre - mixed or diluted coolant to pre-

vent engine over heating, freezing and proper water

pump lubrication

Loading...

Loading...