CYLINDER HEAD 7.2

Valve Adjustment

The engine used in this application uses a solid lifter (tap-

pet) design that requires periodic maintenance of the

rocker arm to valve clearance. (Valve lash)

Valve clearance should be checked every 500 hours of

operation. Always check the valve clearance while the

engine is cold. Correct valve clearance is 0.18 ~

0.22mm (0.0071 ~ 0.0087in).

Procedure to Check / Adjust the Valve Clearance:

1 Park the loader on a level surface, lower the boom

arms, engage the parking brake and shut off the engine.

Remove the ignition key for safety.

2 Allow the engine to cool to room temperature.

3 Access the engine compartment by opening the rear

door and lifting the engine compartment cover.

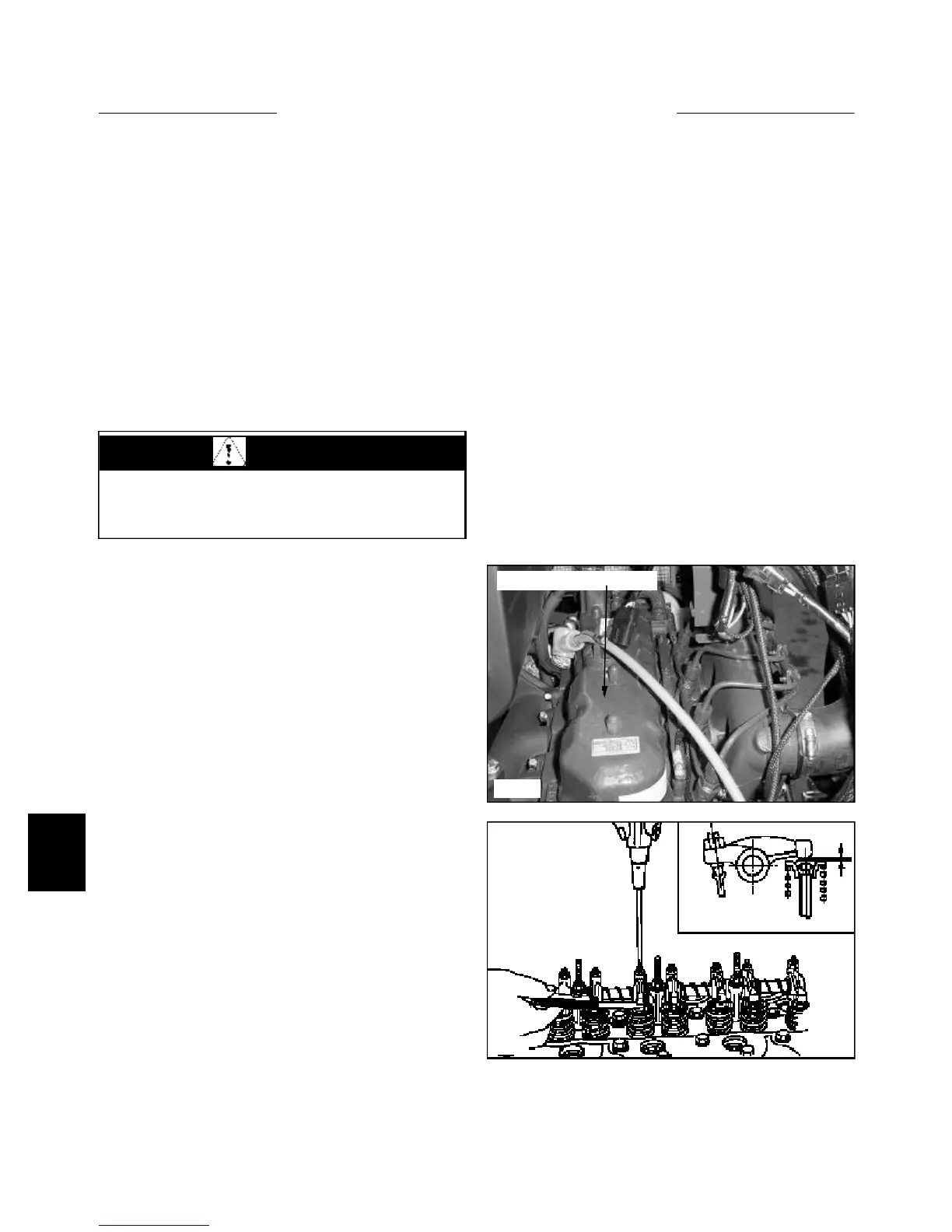

4 Remove the 4 nuts and washers retaining the valve

cover to the engine cylinder head and remove the cover.

(fig. C3613)

NOTE: The crankshaft pairs pistons # 1 and # 4, and pis-

tons # 2 and # 3 to rise and fall at the same time. The

camshaft valve timing though, has the cylinder pairs on

different cycles of operation.

Example: If both pistons on # 1 and # 4 were at top dead

center (TDC), one of the cylinders would be on the com-

pression stroke (both valves closed) the other cylinder

would be starting the intake stroke. (Intake valve starting

to open).

5 Turn the engine over until the intake valve is just

starting to open on number 1 (one) cylinder. (Cylinder

closest to radiator) This valve action means that cylinder

number 4 (next to flywheel) is on the compression stroke,

with both valves closed. This is the proper point to check

and / or adjust the intake and exhaust valves on cylinder

number 4.

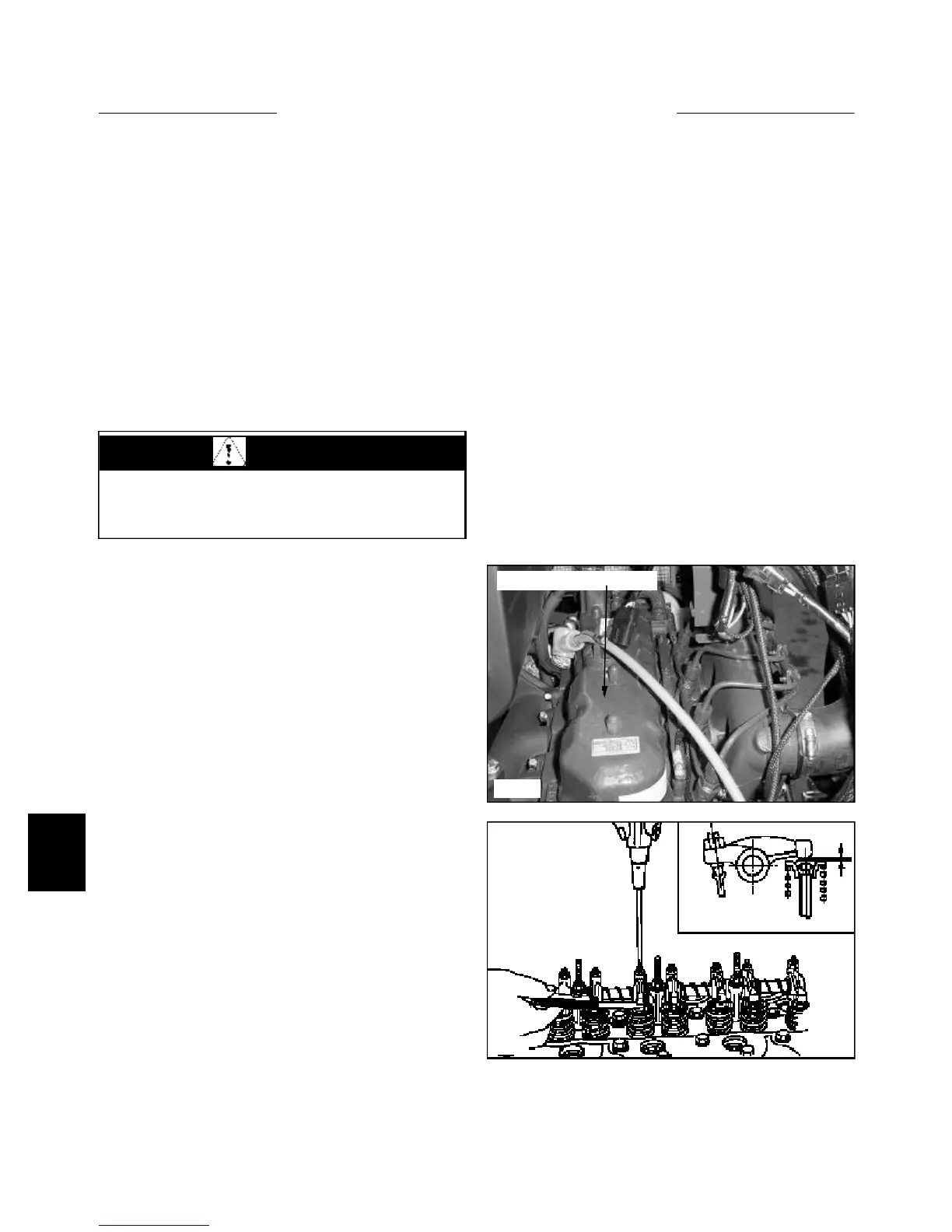

6 Insert a feeler gauge between the rocker arm and the

intake or exhaust valve on cylinder number 4. (fig. C551)

If necessary, loosen the jam nut on top of the rocker arm

and turn the adjustment screw to acquire correct valve

clearance. Correct valve clearance is 0.18 ~ 0.22mm

(0.0071 ~ 0.0087in).

7-12

C3613

C551

Valve / rocker arm cover

7 Rotate the engine after checking / setting cylinder

number 4 valves, until cylinder number 4 intake valve

start to open. This position means that cylinder number 1

(one) is on the compression stroke and can have the

intake and exhaust valves checked and / or adjusted.

Correct valve clearance is 0.18 ~ 0.22mm (0.0071 ~

0.0087in).

8 Repeat the procedure for cylinder pairs 2 and 3. As

one of the cylinders intake valves are just starting to open

the opposite cylinder is on the compression stroke and

can have it’s valves adjusted.

Correct valve clearance is 0.18 ~ 0.22mm (0.0071 ~

0.0087in).

9 Rotate the engine 2 ~ 3 complete revolutions and

recheck the valve clearances by repeating the procedure

above.

10 Replace the valve cover. Tighten the mounting nuts

to 6.9 ~ 8.8 Nm (5.1 ~ 6.6 ft / lbs).

WARNING

Do not adjust the valve clearance while the engine is

hot. Clearances provided are for cold engine adjust-

ment only.

Loading...

Loading...