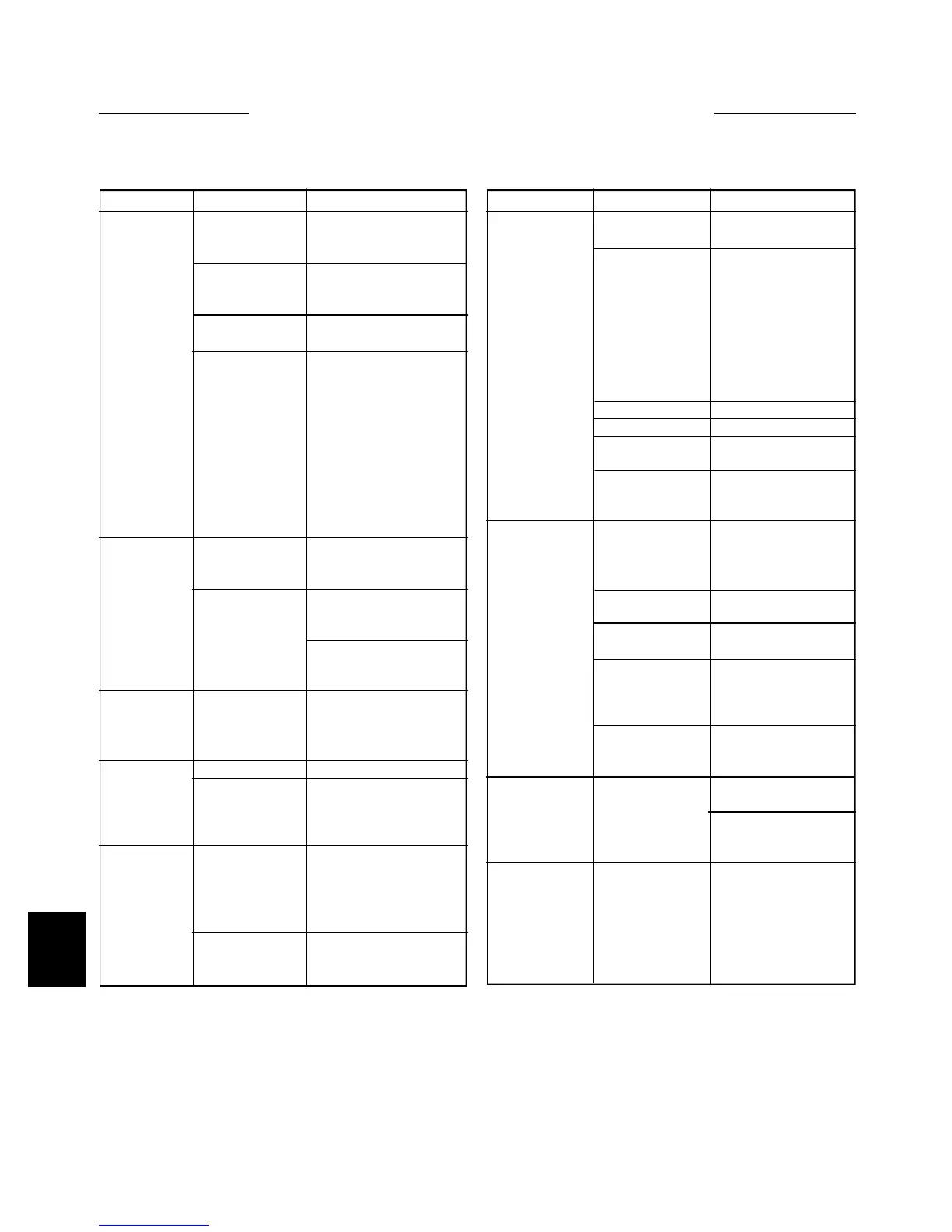

8-10

Adjust, check for wear at

rod ends, loose counter

nuts

Reconnect, check for wear

at rod ends, loose counter

nuts

Replace

Control levers binding

with safety shields or

sound insulation Adjust

control lever bearings

binding in lever assy.

Inspect replace or clean as

required

Inspect linkage for wear at

rod ends, loose counter

nuts

Replace bolt. Ensure bolt

clamping lever to pump

shaft is tight

See troubleshooting hydro-

static system

See troubleshooting hydro-

static system

Adjust

Adjust

See troubleshooting hydro-

static system

Adjust control lever link-

ages

Lubricate

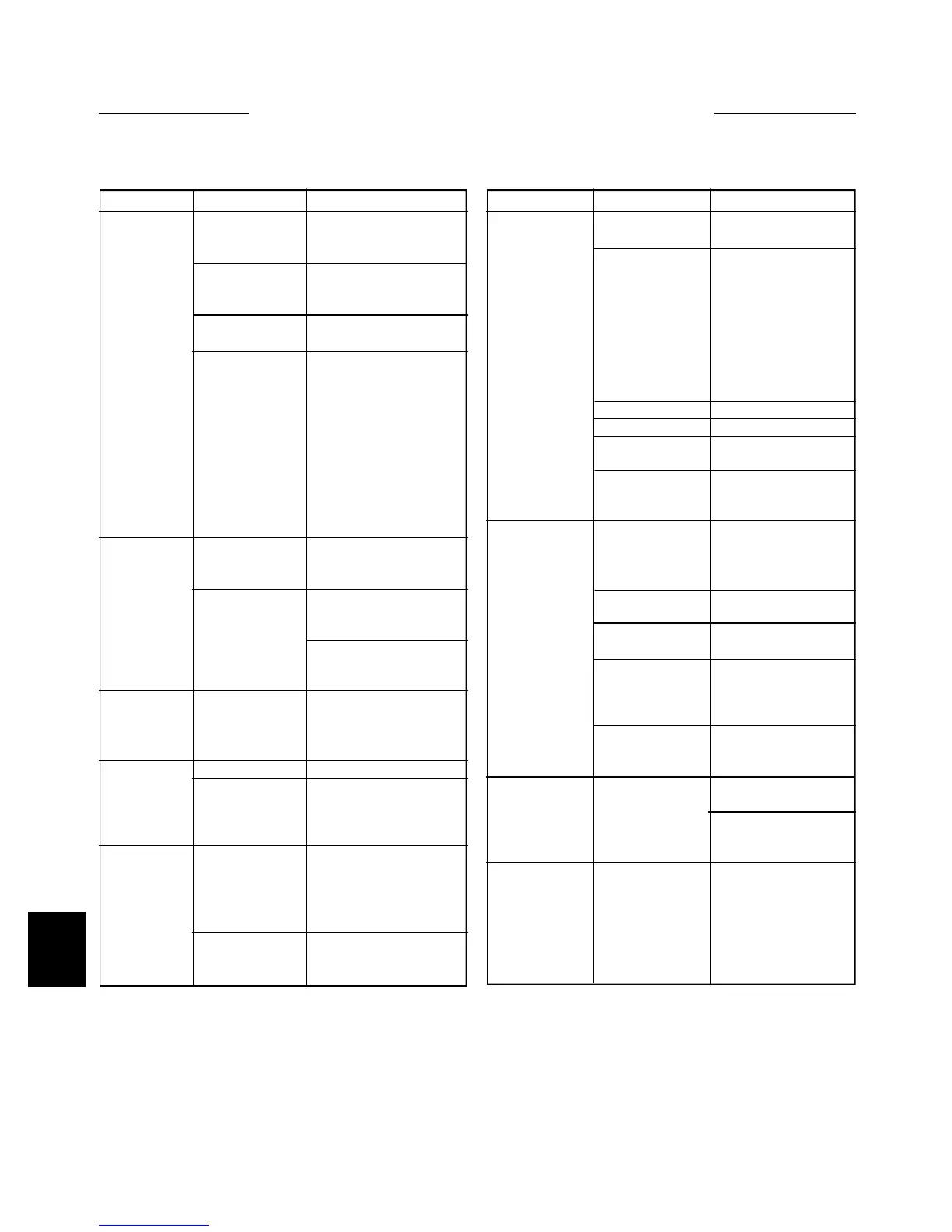

Engine will not

crank over

Engine cranks

over, but will not

start

Loader starts, but

hyd. controls will

not release

Engine will not

stop when the

key is turned

OFF

Control levers

will not center

Machine oper-

ates erratically

Machine loses

power while

turning

Machine will

not travel in

straight line

Control levers

do not operate

smoothly

Linkage out of

adjustment

Linkage discon-

nected

Centering spring

broken

Linkage binding

Control lever link-

age loose

Bolt in pintle lever

loose or broken

Linkage binding

Control lever trav-

el out of adjust-

ment

Internal pump and

/ or motor leakage

Control lever link-

age out of adjust-

ment

Control lever link-

ages need lubrica-

tion

8.2E Control Levers

Battery failure

Battery cable fail-

ure

Starter failure

Fuse burnt

Defective relay

Ignition switch

failure

Auxiliary

hydraulics

engaged

Defective glow

plug relay

Defective glow

plugs

Broken connection

or defective wire

No fuel

Electro solenoid

not releasing valve

spools

Defective ignition

switch

Mechanical dam-

age of the gover-

nor

Check battery, charge

or replace

Check for loose or cor-

roded connectors.

Tighten and clean as

required. Use di-elec-

tric grease to prevent

corrosion.

Check continuity of

cables and replace if

defective

Repair or replace

Check and replace

Check relay continuity

if defective, replace

Check continuity and if

defective, replace

Engine will smoke but

not run unassisted by

starter. Disengage aux.

hydraulics

Check continuity and if

defective, replace

Check continuity and if

defective, replace

Check continuity of the

circuit not functioning

properly in both engine

and ROPS harness.

Check fuel levels and

system

Defective solenoid or

binding solenoid lock.

Check continuity of

connectors and wire.

Check and replace

Check and repair or

replace

8.2F Electrical

Symptom Cause Remedy Symptom Cause Remedy

TROUBLESHOOTING 8.2

Loading...

Loading...