Disassembly

Follow the exploded schematic on the 2nd page of this

section to assist in taking apart the locking mechanism

and to assemble the system back together. Please note that

the quick - tach does not have to be removed to service or

replace locking mechanism parts.

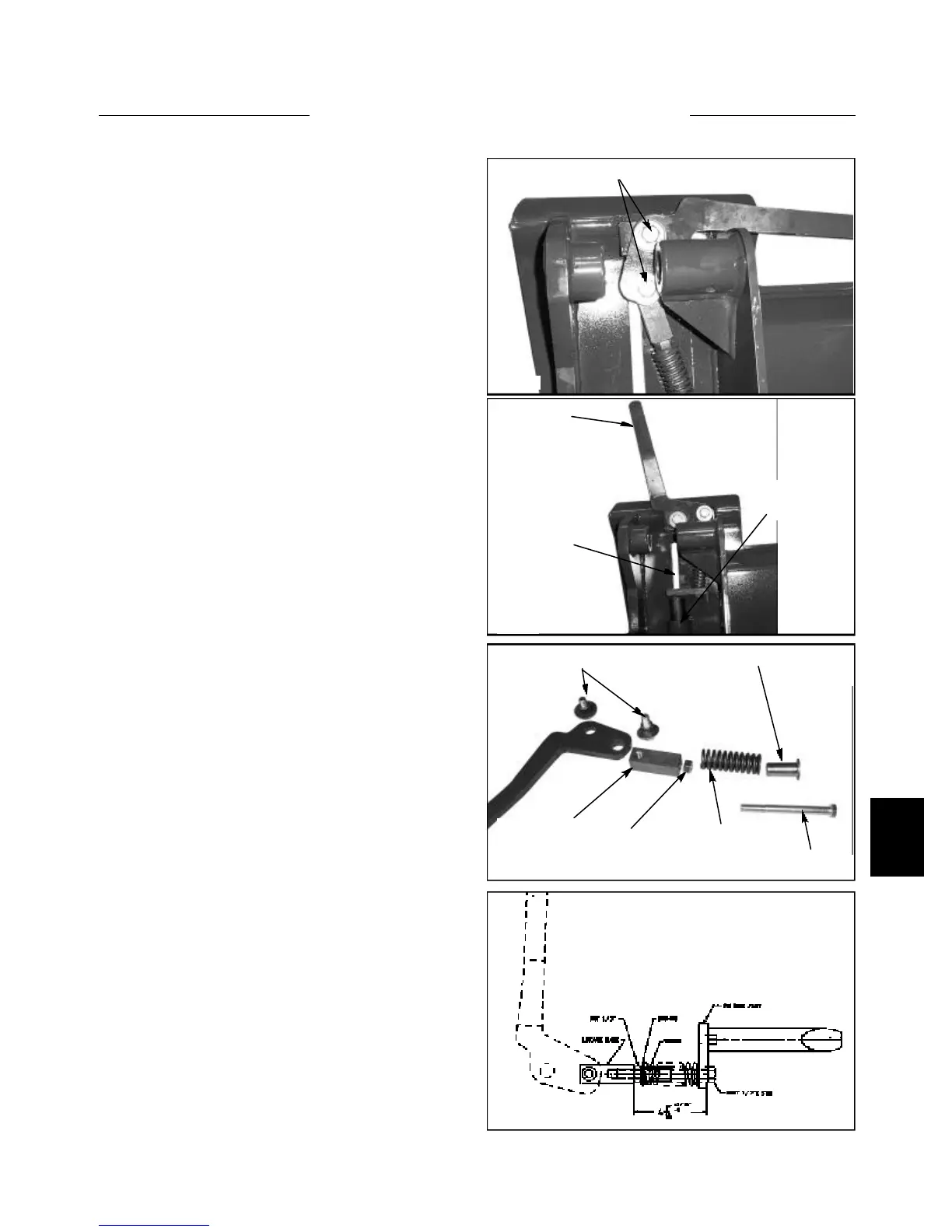

1 Remove the bolt retaining the lock handle to the lock

linkage. (fig. C3594)

2 Remove the bolt retaining the lock handle to the

quick - tach frame. (fig. C3594)

3 Pull the locking pin and linkage out of the guide

bushing. (fig. C3595)

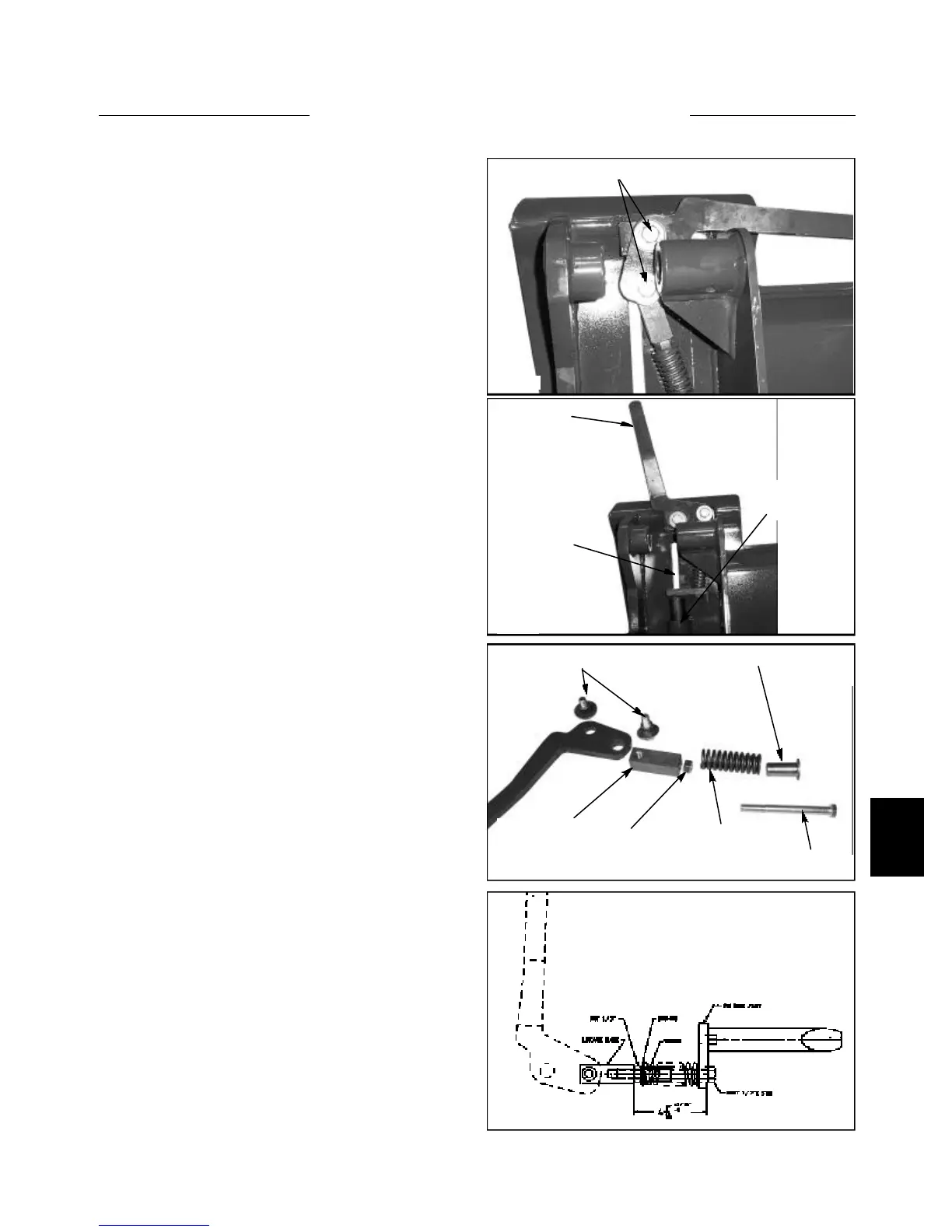

4 Loosen the jam nut on the linkage block. Remove the

bolt holding locking pin to the lock linkage block.

5 Separate the parts and inspect the spring for broken

or sacking (compressed) coils. (fig. C3596) Replace parts

as required.

6 Inspect the locking pin for wear. Make sure the

beveled end of the pin is not worn or broken off the oppo-

site side of the bevel. Check the fit of the pin in the quick

- tach guide bushing. If the pin or bushing is excessively

worn replace the pin or complete quick - tach assembly.

7 Inspect the lock handle mounting holes for fit against

the handle pivot bushings. Replace the handle or pivot

bushings as required if the fit is sloppy. (fig. C3596)

8 Check the fit of the lower pivot pins in the quick -

tach. Discard worn pins and replace the hardened bush-

ings in the quick - tach if so equipped.

9 Check and replace any grease fittings that are dam-

aged or defective.

6-5

C3594

C1818

C3596

C3595

Assembly

Upon assembling the locking mechanism to the quick -

tach, use 242 Loctite (blue) on all the mounting nuts and

bolts.

1 When assembling the locking pin to the spring, bush-

ing and linkage block, adjust the length of the bolt to 4

1/16 inches. (103mm). This is measured from under the

head of the bolt up to, and against the linkage block. (fig.

C1818) This is very crucial for lock pin engagement to

the attachment.

2 Replace the rest of the lock mechanism in the reverse

order above.

3 Lubricate all pins and bushings.

4 Check the lock mechanism by cycling the lock levers

to ensure correct engagement through the attachment and

sufficient pressure to hold the lock system down in the

over - center position. (Engages and stay in the locked

position)

Linkage bolt measurement

Pivot bushing Stabilizer bushing

Bolt

Spring

Jam nut

Linkage block

Q / T handle bolts

Handle

Lock pin

Lock pin

guide bushing

QUICK - TACH 6.1

Loading...

Loading...