ENGINE MAINTENANCE 7.1

Universal Joint

The engine drive universal is located and accessed by

removing the operators seat, and removing the service

access cover. The universal joint should be serviced every

50 hours. Check the universal joint for wear and lubricate

with a standard grade of muti purpose grease.

To Service the U- Joint:

1 Remove any attachment, raise the boom arms,

engage the boom supports, engage the parking brake and

shut off the engine. Remove the ignition key.

2 Remove the seat assembly. Be sure to disconnect the

electrical plug on the seat switch, left hand side.

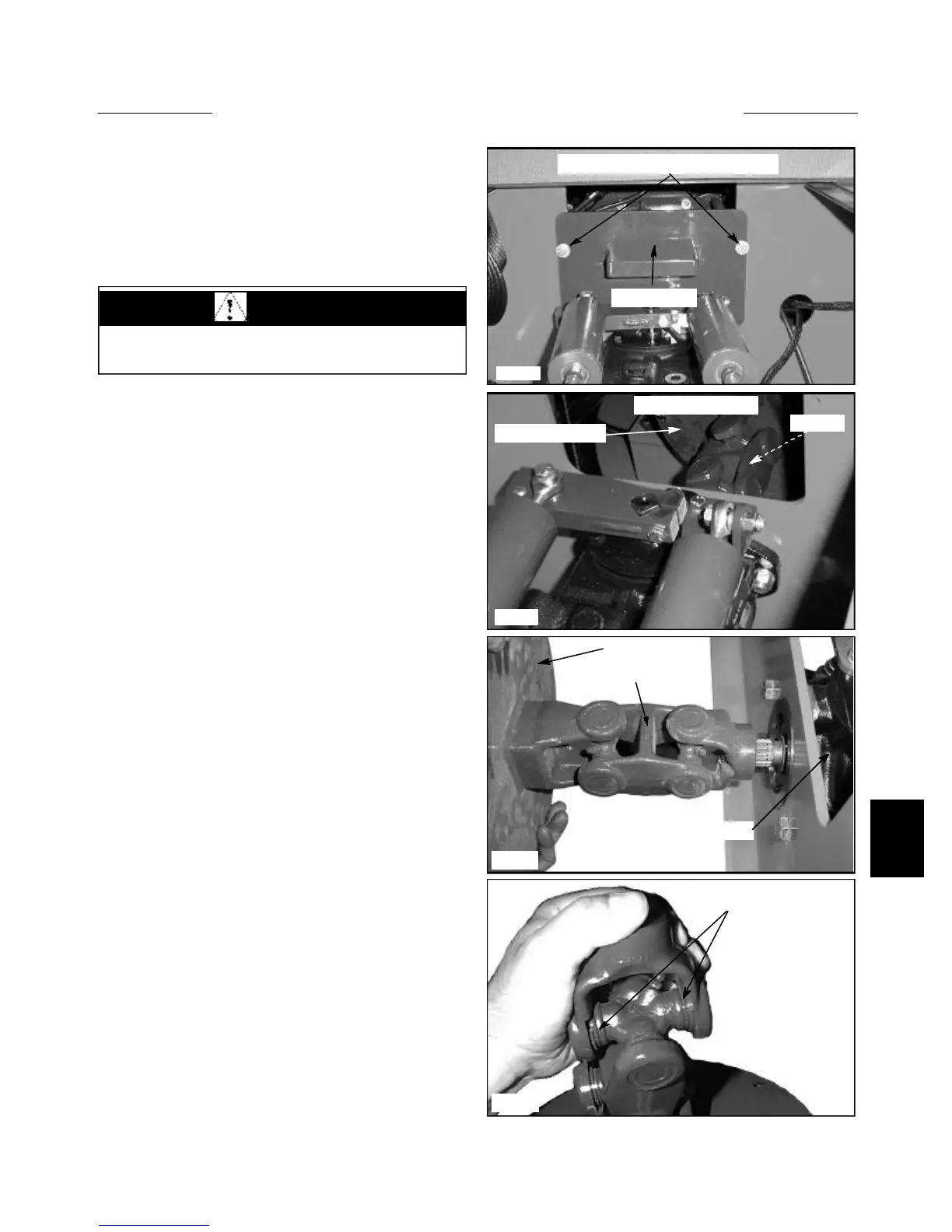

3 Remove the service access panel, located below the

battery compartment cover, by removing the 2 bolts and

lifting and pulling forward from the top. (fig. C3628)

4 Grasp the U- Joint assembly with your hands and

rotate the joint left and right, forward and back to check

U- Joint wear.

5 Check the condition of the splined yoke and spline

on the hydrostatic pump input shaft.

4 Rotate the U- Joint if necessary to locate the grease

fittings on the U- Joint crosses. Apply 2 ~ 3 pumps of

multi purpose grease to each U- Joint cross.

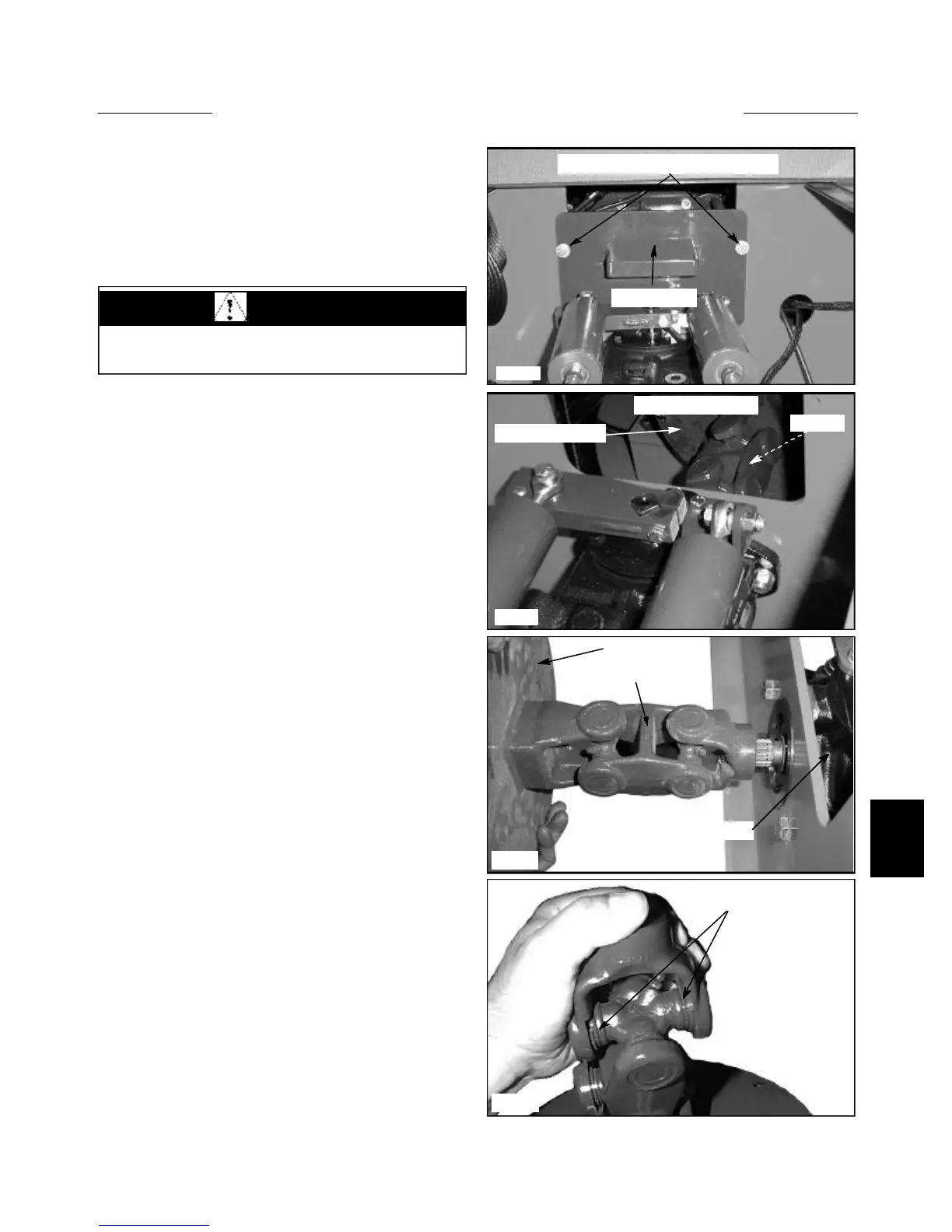

NOTE: Remove the U- Joint assembly from the loader to

replace worn U- Joints. (fig. C2226) The U- Joints are

retained by internal snap ring clips. Loosen the engine

mounting isolators to move the engine rearward enough

to allow the engine U-joint to come off the hydraulic tan-

dem pump splined shaft.

7-11

C3628

C2226

C3630

C3629

U- Joint assembly

Engine flywheel

Hydrostatic pump

U-Joint service access panel bolts

Lift and pull

Service panel open

Engine flywheel

U- Joint

U- Joint snap ring

WARNING

Never work under the boom arms without the boom

supports engaged

Loading...

Loading...