OPERATING MANUAL TW63 MAINTENANCE / SERVICE

ThyssenKrupp Aufzugswerke GmbH

7. Maintenance / service

Maintenance period: Maintenance of the machine should take place within

the framework of central maintenance of the elevator, at least once a year.

Note: Commissioning and maintenance work may only be carried out by

trained and instructed qualified personnel.

All laws and regulations for elevator systems as well as accident prevention

regulations must be known and complied with.

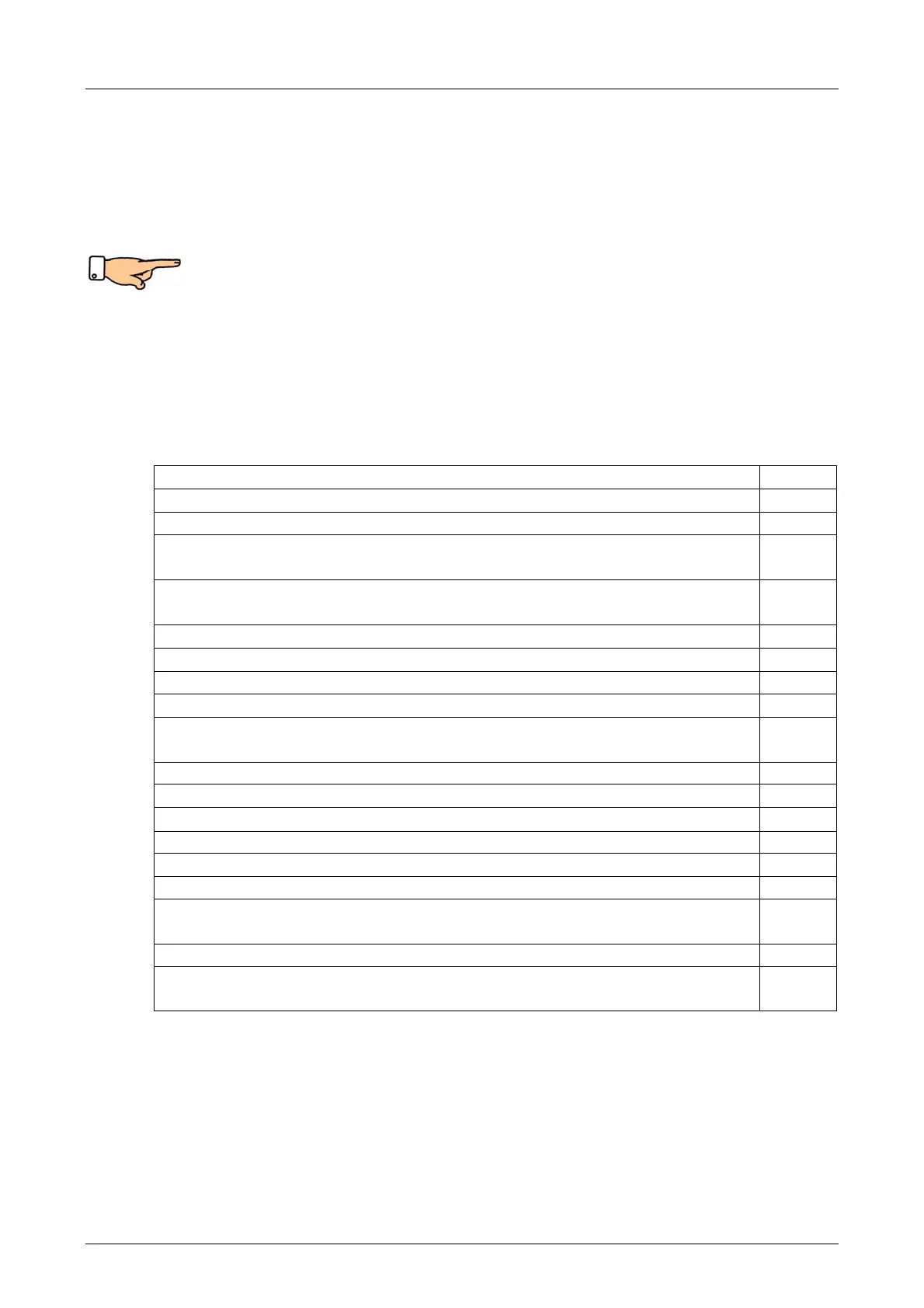

More details on the sequence, settings and data can be found in

Chapter:

Check the oil level; top up if necessary

7

Change the oil (when the change date is reached)

7

Check the brake shoes for wear; the remaining lining thickness

must be at least 3 mm

7

Check the brake setting; the block stroke should be 0.3 + 0.1 mm

7

Check the braking deceleration

7

Check the armature base plate setting and its ease of movement

7

Check worm gear toothing for wear

Check the backlash between the worm shaft and worm wheel,

0.04 mm to 0.12 mm at 20° C

7

Check groove profile on the traction sheave for damage and wear

Check secure seating of bolts of the traction sheave mount

9

Check pulley grooves for damage and wear

Check proper and adequate condition and safety of electrical

connections

Check that protective and safety devices are present and

correctly set

Loading...

Loading...