OPERATING MANUAL TW63 MAINTENANCE / SERVICE

ThyssenKrupp Aufzugswerke GmbH

7.1 Lubrication

Lubricant Replacement interval Vertical

motor

Filling

amount

Synthetic gear oil SM1 For the first time after 4

years

then every 8 years

Vertical = 11 litres

Horizontal = 9 litres

Oil change

Before the oil change, run the gear until it reaches operating temperature.

Discharge the gear oil by removing the cap on the oil drain pipe.

Collect the old oil in a container specifically designed for the purpose.

Close the oil drain after discharging the gear with sealing tape and the

cap.

Fill the machine with the prescribed amount of oil

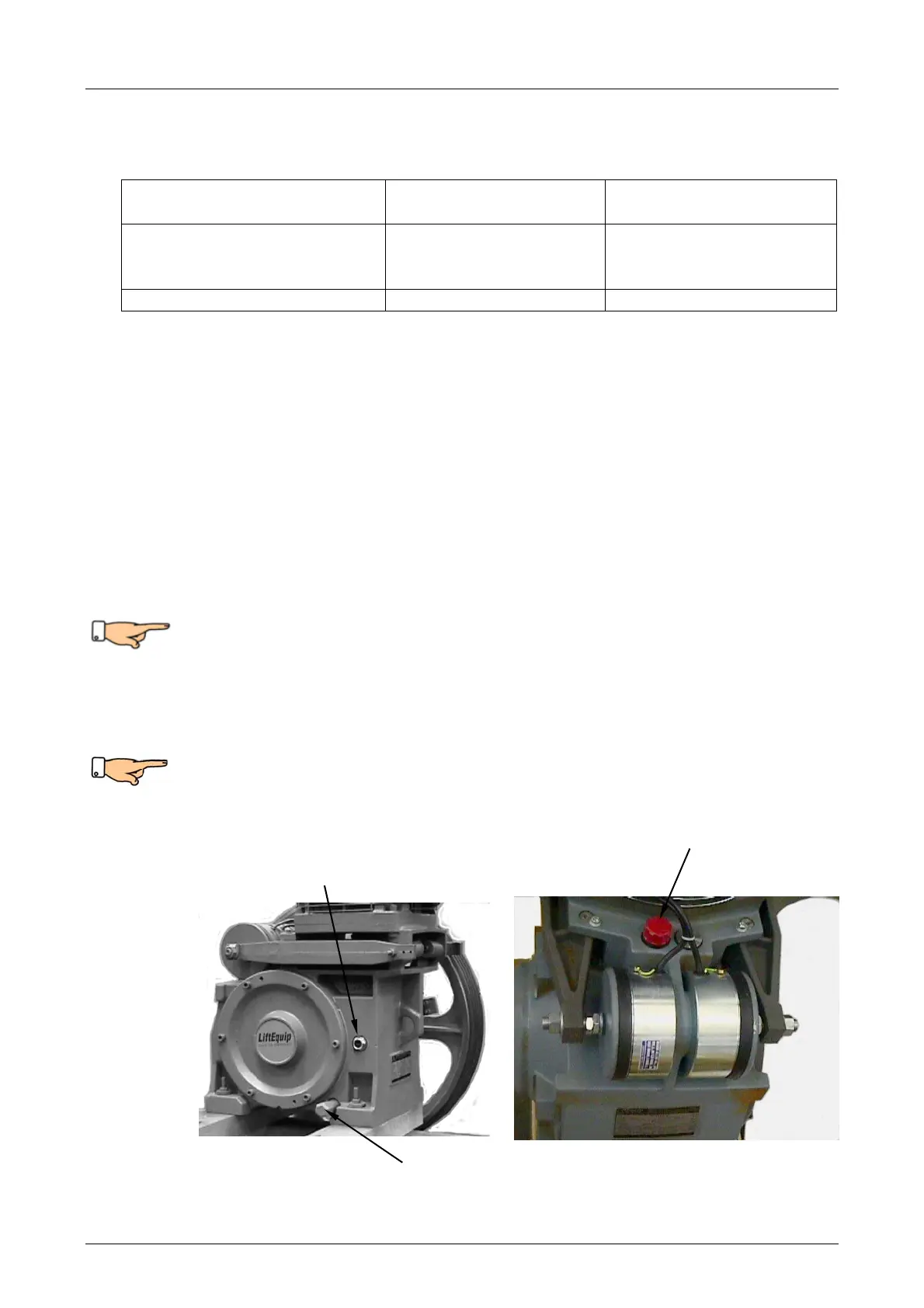

through the upper opening on the gear box casing (red cap, see Fig.

7.1.2).

Check the level at the oil gauge glass (see Fig 7.1)

Enter the date for the next oil change in the type plate on the gear box

casing.

Never mix various types of oil.

Do not let any oil seep through to the groundwater.

Dispose of old oil as well as cleaning cloths contaminated with oil and

grease according to applicable regional regulations.

Use only lubricants approved by THYSSENKRUPP AUFZUGSWERKE.

Note: THYSSENKRUPP AUFZUGSWERKE GmbH shall not be liable for

losses caused by the use of non-approved lubricants.

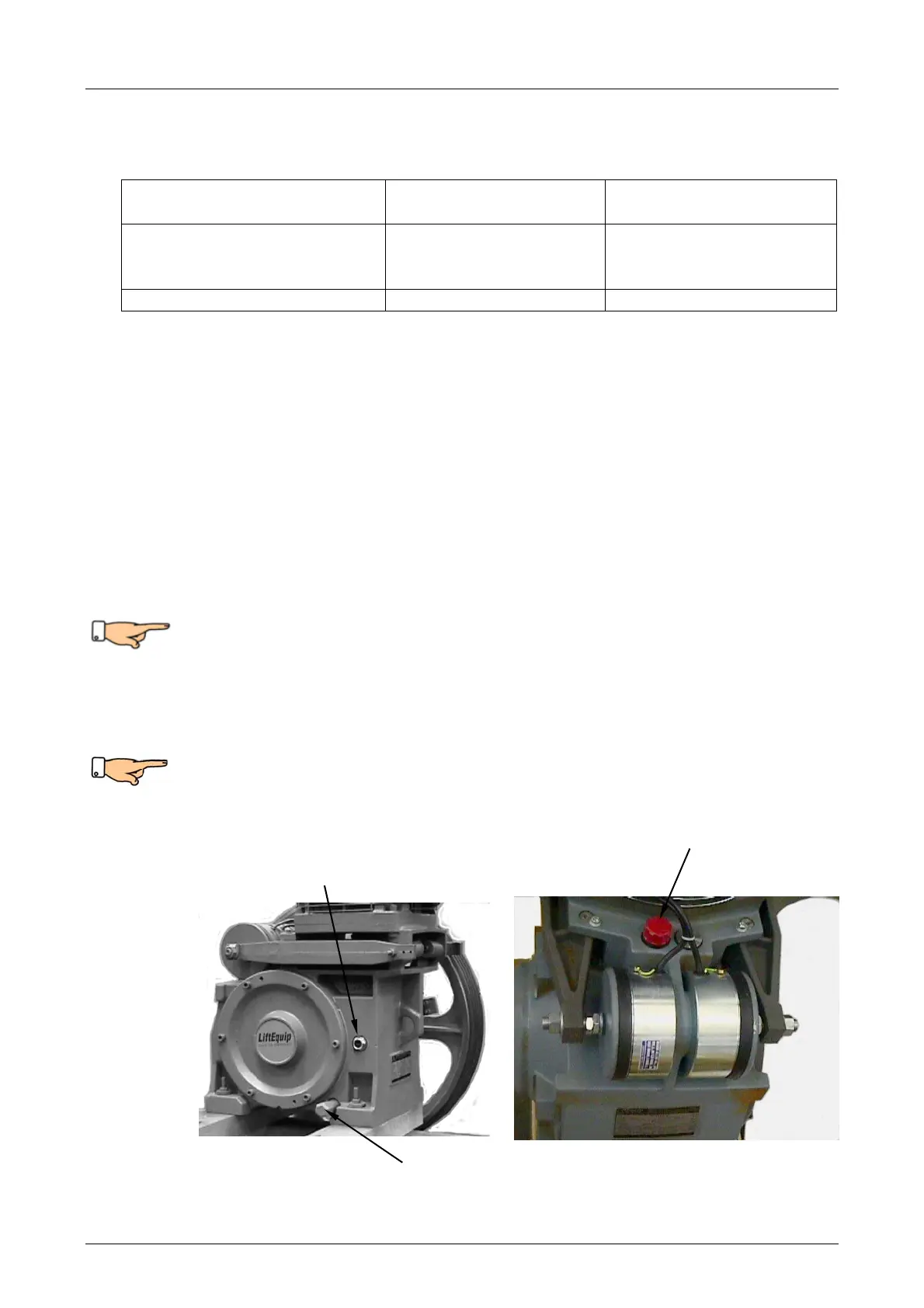

Version with vertical motor position

Fig. 7.1.1

Oil filling hole

Fig. 7.1.2

Oil gauge glass

Oil drain

Loading...

Loading...