ii

4st 9.9/15/20 2008

About this manual

This service manual is designed so that service persons are able to perform their work correctly.

Understand the following matters well for efficient repairs.

1 Each chapter begins with the introduction of special tools that are used for the work described in the

chapter so that the service persons are able to figure out the tools needed.

2 Parts that are serviced in each chapter and their details are presented by using a component composition

diagram.

3 Fastening torques are described in the component composition diagram and in the body text and are

critical points of the applicable repair.

4 Pictograms indicate that there is an important instruction for the relevant parts. It also shows the type of

lubricant and its application point(s).

5 The component composition diagrams describe the names of the parts, the quantity of the parts used,

size of fasteners and special notes.

6 Specific works are described in detail by using illustrations and adding advice on the work.

6-12

Lower Unit

4st 9.9/15/20 2008

Do not reuse removed bearing.

3. Use commercially available universal puller plate to remove

ball bearing.

4

3

2

3

4. Use a press to remove oil seal 2 and needle bearing 3 at

the same time.

Before removing, check bearing for play or

deflection. Replace if necessary.

Before removing, check bearing for play or

deflection. Replace if necessary. Direct

attachment with side without O-ring to needle

bearing.

Do not reuse removed bearing.

Needle Bearing Attachment 3 :

P/N. 3BA-99710-0

Driver Rod 4 :

P/N. 3AC-99702-0

2 Oil seal

3 Needle bearing

Do not reuse.

Do not reuse.

10)

Disassembly of Propeller Shaft Housing

1. Tighten universal puller plate to make gap between reverse

gear (C gear) and propeller shaft housing.

2. Remove reverse gear (C gear) ass'y by putting two bladed

screw drivers into the gap to force the gap to open.

Universal Puller Plate :

P/N. 3AC-99750-0

6-4

Lower Unit

4st 9.9/15/20 2008

18

20

19

17

1

1-1

5

3

5

4

8

7

6

10

9

2

2

11

12

13

14

21

22

16

15

5

3

14N·m (10 lb·ft) [1.4 kgf·m]

TB

1342342134 2

1342

G

R

E

A

SE

OBMOBMOBM

OBM

OIL

GEARGEARGEAR

GEAR

O

IL

GEARGEARGEAR

GEAR

O

IL

GEARGEARGEAR

GEAR

TB

1342342134 2

1342

19 N·m (14 lb·ft) [1.9 kgf·m]

24 N·m (17 lb·ft) [2.4 kgf·m]

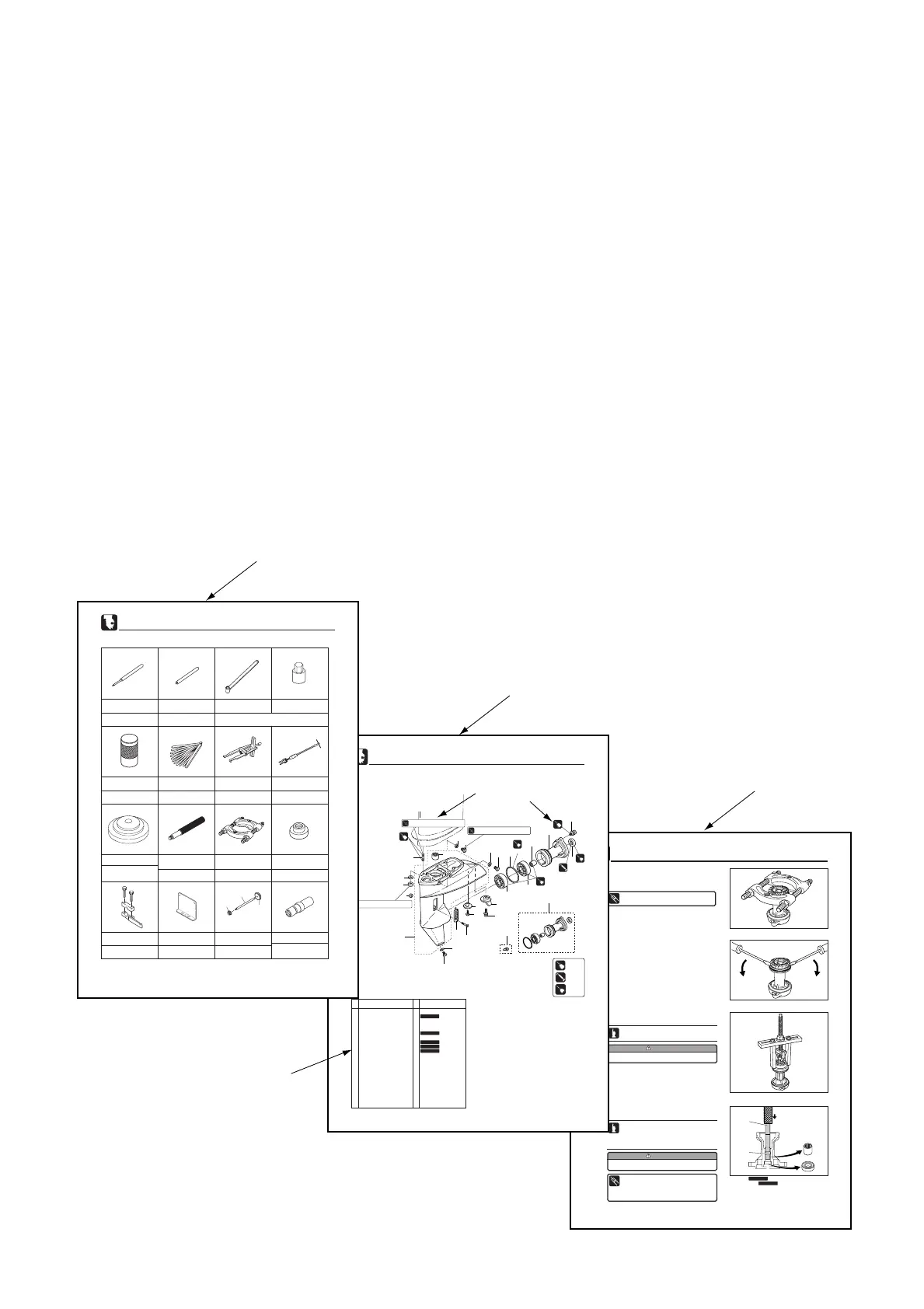

2.Parts Layout

Gear Case

1 Gear Case 1

1-1 Needle Bearing 1

2 Ball Bearing, 6205HS 2

3 Oil Plug 2

4 Water Plug 1

5 Gasket, 8.1-15-1 3

6 Propeller Shaft Housing 1

7 Needle Bearing, 17-24-20 1

8 O-Ring, 2.4-59.6 1

9 Oil Seal, 17-30-9 1

10 Bolt 2

11 Trim Tab 1

12 Bolt 1

13 Sub Water Strainer 1

14 Screw 1

15 Water Strainer 2

16 Screw 1

17 Nylon Nut, 4P-0.7 1

18 Stud Bolt 4

19 Nut 4

20 Washer, 8.1-16-1.5 4

21 Propeller Shaft Housing Ass'y 1

22 Sub Water Pipe Plug 1 Option

Ref.

No.

Description

Remarks

Q'ty

O

IL

GEARGEAR

GEAR

OBM

1342

P/L Fig. 14

Do not reuse.

Do not reuse.

Do not reuse.

Do not reuse.

Do not reuse.

6-2

Lower Unit

4st 9.9/15/20 2008

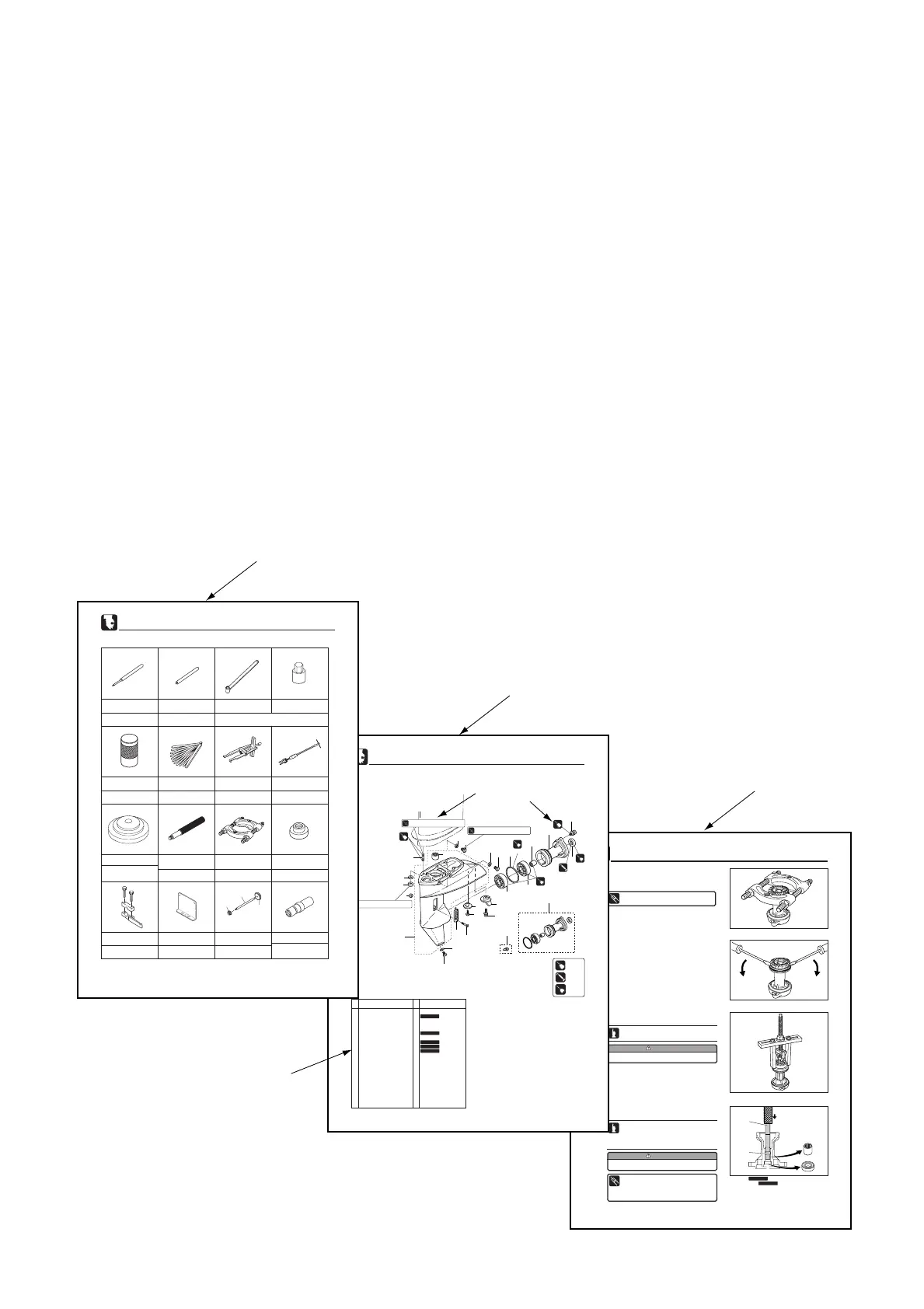

1.Special Tools

Removing spring pin

Spring Pin Tool A

P/N. 345-72227-0

Used with driver rod and needle

bearing attachment

Positioning propeller shaft housing

needle bearing

Driver Rod

P/N. 3AC-99702-0

Center Plate

P/N. 3AC-99701-0

Used with center plate and

needle bearing attachment

Used with driver rod Installing oil

seal in the propeller shaft housing

Oil Seal Attachment 2

P/N. 3AG-99820-0

Installing forward (A) gear

bearing

Removing/installing Pinion (B) Gear Nut

Bevel Gear Bearing Installation Tool

P/N. 346-72719-0

Bevel Gear B Nut Wrench

P/N. 346-72231-0

Bevel Gear B Nut Socket

P/N. 346-72232-0

Slide Hammer Kit

P/N. 3AC-99080-0

Removing forward (A) gear

bearing outer race

Universal Puller Plate

P/N. 3AC-99750-0

Removing forward (A) gear

bearing outer race

Bevel Gear Bearing Puller Ass'y

P/N. 3A3-72755-0

Installing spring pin

Spring Pin Tool B

P/N. 345-72228-0

Installing forward gear (A)

bearing outer race

Bearing Outer Press Kit

P/N. 3B7-72739-1

Removing reverse

gear/bearing

3BJ-72733-0

3B7-72731-0

3BJ-72732-0

Needle Bearing Attachment

P/N. 3BA-99710-0

Used with driver rod and center plate

Installing propeller shaft housing

needle bearing

Measuring gaps

Thickness Gauge

P/N. 353-72251-0

Measuring backlash

Backlash Measuring Tool Clamp

P/N. 3B7-72720-0

ø110 x ø71 ø29.5 x ø16.5

Used to attach dial gauge

whwn measuring backlash

Dial Gauge Plate

P/N. 3B7-72729-0

E_MFS20C_ch00_081218.qxd 09.1.20 5:09 PM ページ 2

Loading...

Loading...