6-22

Lower Unit

4st 4/5/6 2011

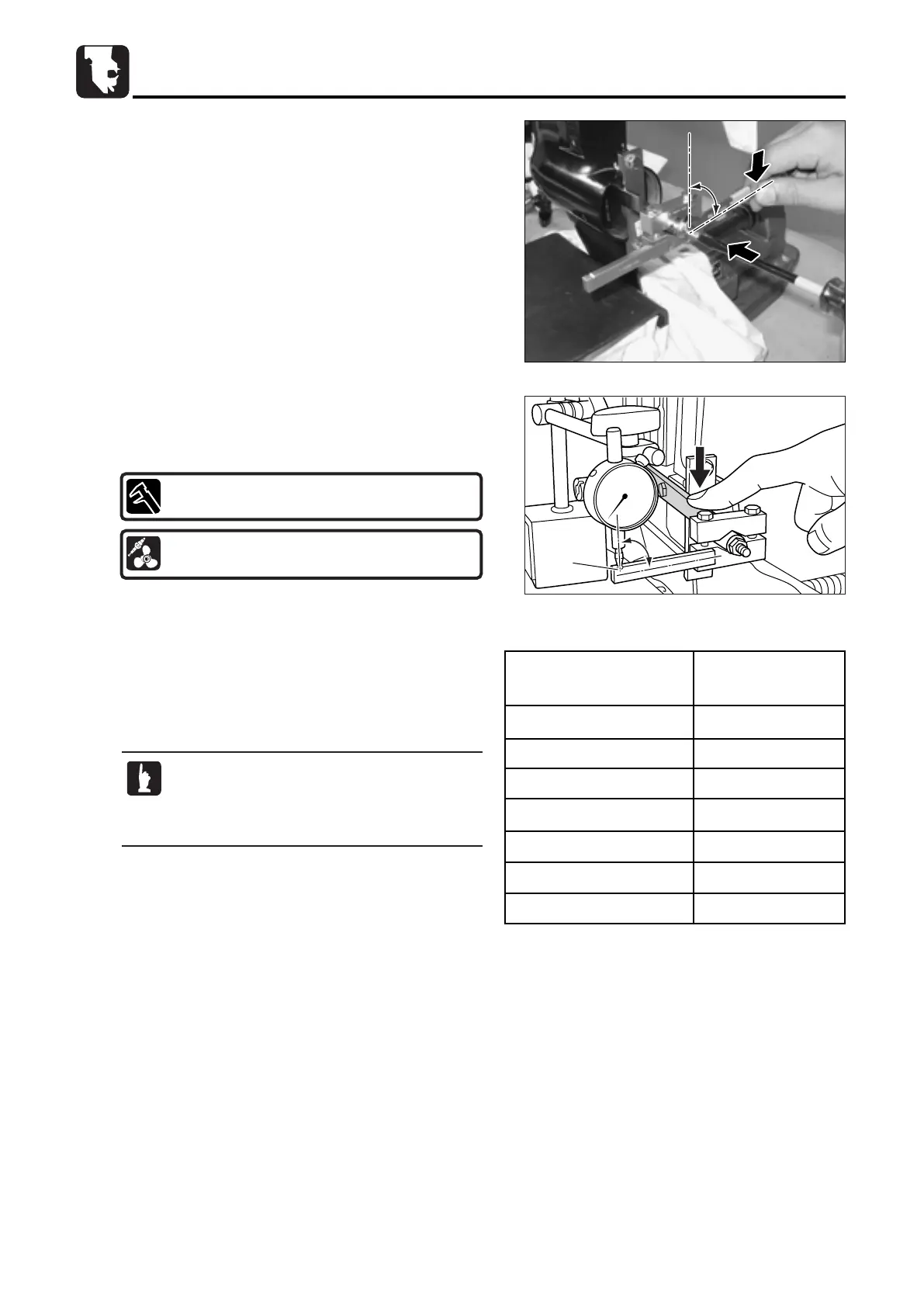

4. Perform shim adjustment at pinion (B) gear side as

necessary based on the gauge value obtained. The table

shows relation between dial gauge readings and shim

adjustments.

3. Secure clamp halves A and B to shaft B using bolts. Move

clamp A while pushing arm in direction a, and read dial

gauge at notch groove b position.

Gauge Reading Shim Adjustment

mm mm

0.00 - 0.15 -0.10

0.16 - 0.49 0

0.50 - 0.52 +0.25

0.53 - 0.59 +0.30

0.60 - 0.65 +0.35

0.66 - 0.71 +0.40

0.72 - 0.77 +0.45

2. First, pull up drive shaft by using hand.

Fix shaft B with bladed screw driver, and tighten nut while

pushing the shaft. At this time, be careful not to overtighten

the nut, or shaft B is locked.

Tighten nut fully by using fingers, and then, additionally

tighten approximately 90 degrees by using spanner wrench.

During the work, fix shaft B by using bladed screw driver.

1.Values in this table indicate dial gauge readings

that are obtained when using special tool.

2.Change gear engagement position and

measure backlash again for check.

Sizes of Adjusting Shims :

For Pinion (B) Gear Side : 0.1, 0.15mm

Proper Backlash Obtained from Gauge Reading :

0.16 - 0.49mm (0.0063 - 0.0193 in)

MFS4-5-6Ech06110422.qxd 11.4.22 5:50 PM ページ22

Loading...

Loading...