Drive System

Maintenance

Servicing the T racks

Cleaning the T racks

Service Interval : Before each use or daily

Check the tracks for excessive wear and clean them

periodically . If the tracks are worn, replace them.

1. Park the machine on a level surface, engage

the parking brake (if applicable), and lower the

grinder .

2. Shut of f the engine and remove the key .

3. Using a water hose or pressure washer , remove

dirt from each track system.

Important: Ensure that you use high-pressure

water to wash only the track area. Do not use

a high-pressure washer to clean the rest of the

machine. High-pressure washing can damage the

electrical system and hydraulic valves or deplete

grease.

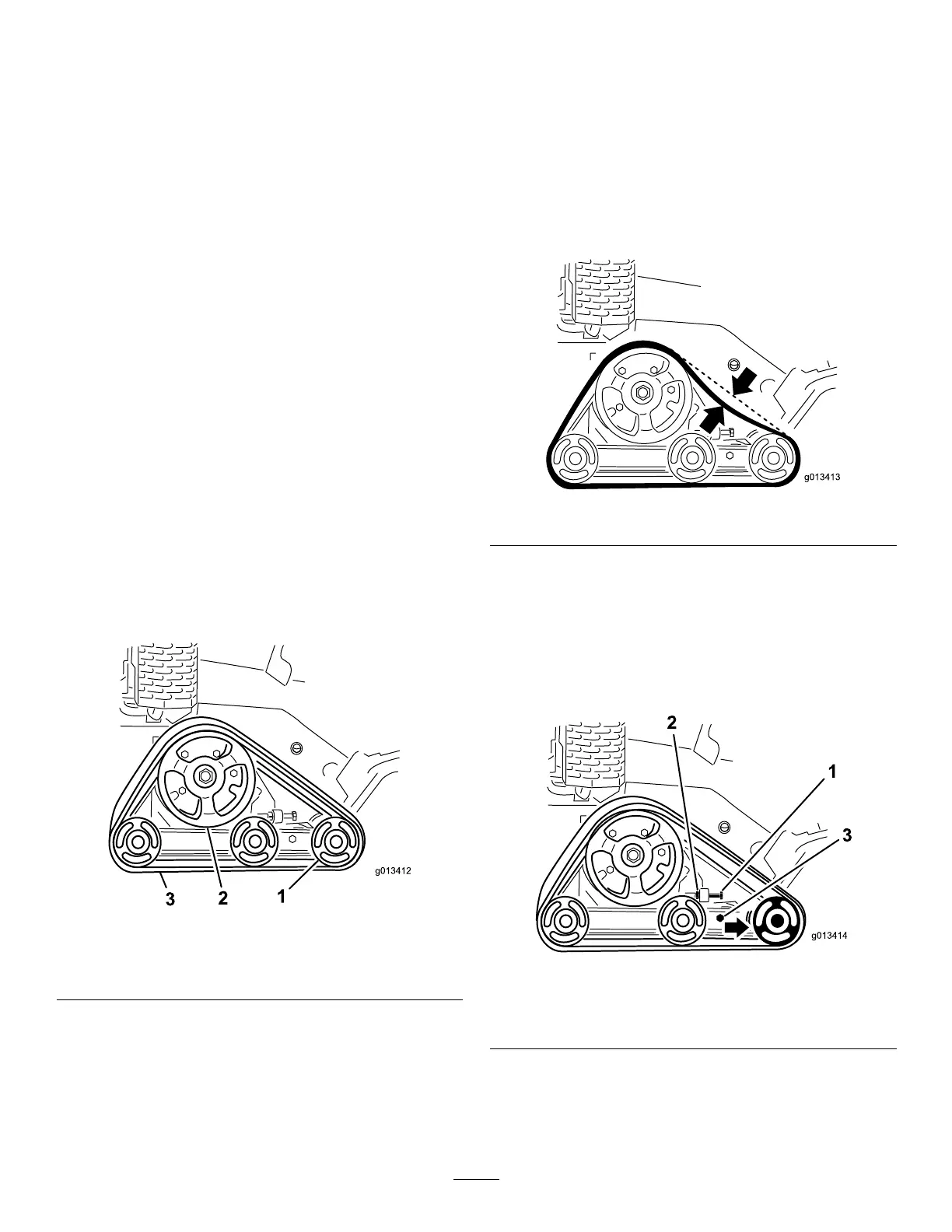

Important: Ensure that you fully clean the road

wheels and the drive wheel ( Figure 41 ). The road

wheels should rotate freely when clean.

g013412

Figure 41

1. Road wheels 3. T rack

2. Drive wheel

Checking and Adjusting the T rack

T ension

Service Interval : After the rst 50 hours

Every 100 hours

T o check the tension of each track, place 20.4 kg (45

lb) on the track midway between the front road wheel

and the drive wheel. The track should ex no more

than 0.6 to 1 cm (1/4 to 3/8 inch). If it does, adjust the

track tension using the following procedure:

g013413

Figure 42

1. Park the machine on a level surface, engage

the parking brake (if applicable), and lower the

grinder .

2. Shut of f the engine and remove the key .

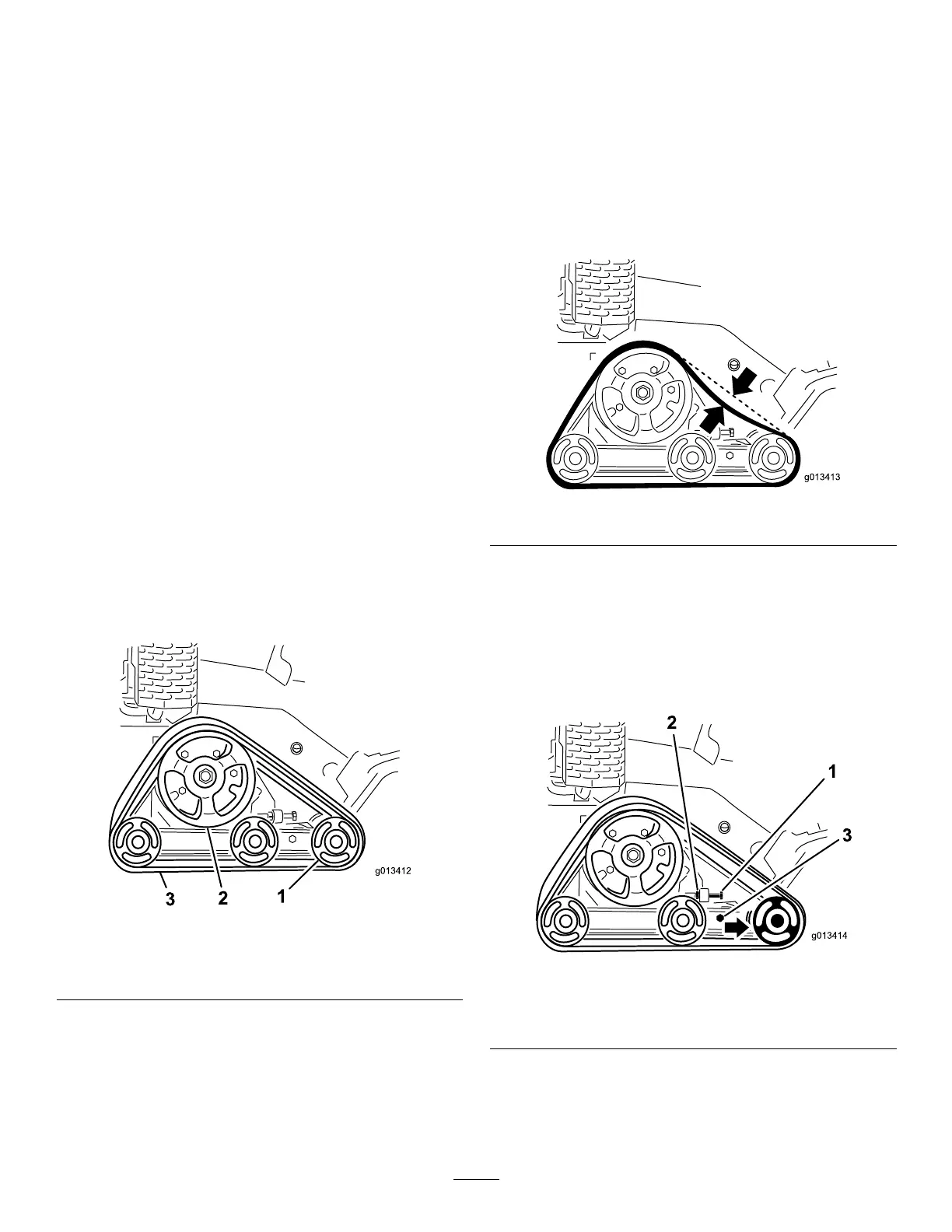

3. Loosen the jam nut on the track tensioning bolt

and the clamp bolts on the tension arm ( Figure

43 ).

g013414

Figure 43

1. T ensioning bolt

3. Clamp bolts

2. Jam nut

4. T orque the tensioning bolt to 32.5 to 40 N∙m (24

to 30 ft-lb) to tighten the track ( Figure 43 ).

5. Ensure that the track deects less than 0.6 to 1

cm (1/4 to 3/8 inch) when 20.6 kg (45 lb) of force

31

Loading...

Loading...