Hydraulic System

Maintenance

Hydraulic System Safety

• Seek immediate medical attention if uid is injected

into skin. Injected uid must be surgically removed

within a few hours by a doctor .

• Ensure that all hydraulic-uid hoses and lines are

in good condition and all hydraulic connections

and ttings are tight before applying pressure to

the hydraulic system.

• Keep your body and hands away from pinhole

leaks or nozzles that eject high-pressure hydraulic

uid.

• Use cardboard or paper to nd hydraulic leaks.

• Safely relieve all pressure in the hydraulic system

before performing any work on the hydraulic

system.

Hydraulic Fluid

Specications

Every 1,500 hours/Every 2 years (whichever

comes rst)

Hydraulic T ank Capacity: 23 L (6 US gallons)

Use only 1 of the following uids in the hydraulic

system:

• T oro Premium T ransmission/Hydraulic T ractor

Fluid (refer to your Authorized Service Dealer for

more information)

• T oro Premium All Season Hydraulic Fluid

(refer to your Authorized Service Dealer for more

information)

• If either of the above T oro uids are not available,

you may use another Universal T ractor

Hydraulic Fluid (UTHF ), but they must be only

conventional, petroleum-based products. The

specications must fall within the listed range for

all the following material properties and the uid

should meet the listed industry standards. Check

with your hydraulic uid supplier to determine if the

uid meets these specications.

Note: T oro will not assume responsibility for

damage caused by improper substitutions, so use

only products from reputable manufacturers who

will stand behind their recommendations.

Material Properties

cSt at 40°C: 55 to 62V iscosity , ASTM D445

cSt at 100°C: 9.1 to 9.8

V iscosity index, ASTM D2270

140 to 152

Pour Point, ASTM D97 -37 to -43°C (-35 to -46°F)

Industry Standards

API GL-4, AGCO Poweruid 821 XL, Ford New Holland

FNHA-2-C-201.00, Kubota UDT , John Deere J20C, V ickers

35VQ25 and V olvo WB-101/BM

Note: Many hydraulic uids are almost colorless,

making it dif cult to spot leaks. A red dye additive

for the hydraulic system uid is available in 20 ml

(0.67 oz) bottles. One bottle is suf cient for 15 to

22 L (4 to 6 US gallons) of hydraulic uid. Order

Part No. 44-2500 from your Authorized Service

Dealer .

Checking the

Hydraulic-Fluid Level

Service Interval : Every 25 hours

Refer to Hydraulic Fluid Specications ( page 37 ) .

1. Park the machine on a level surface, engage

the parking brake (if applicable), and lower the

grinder .

2. Shut of f the engine and remove the key .

3. Look into the glass bubble on the right side of

the machine. If you cannot see hydraulic uid in

the bubble, continue this procedure to add uid.

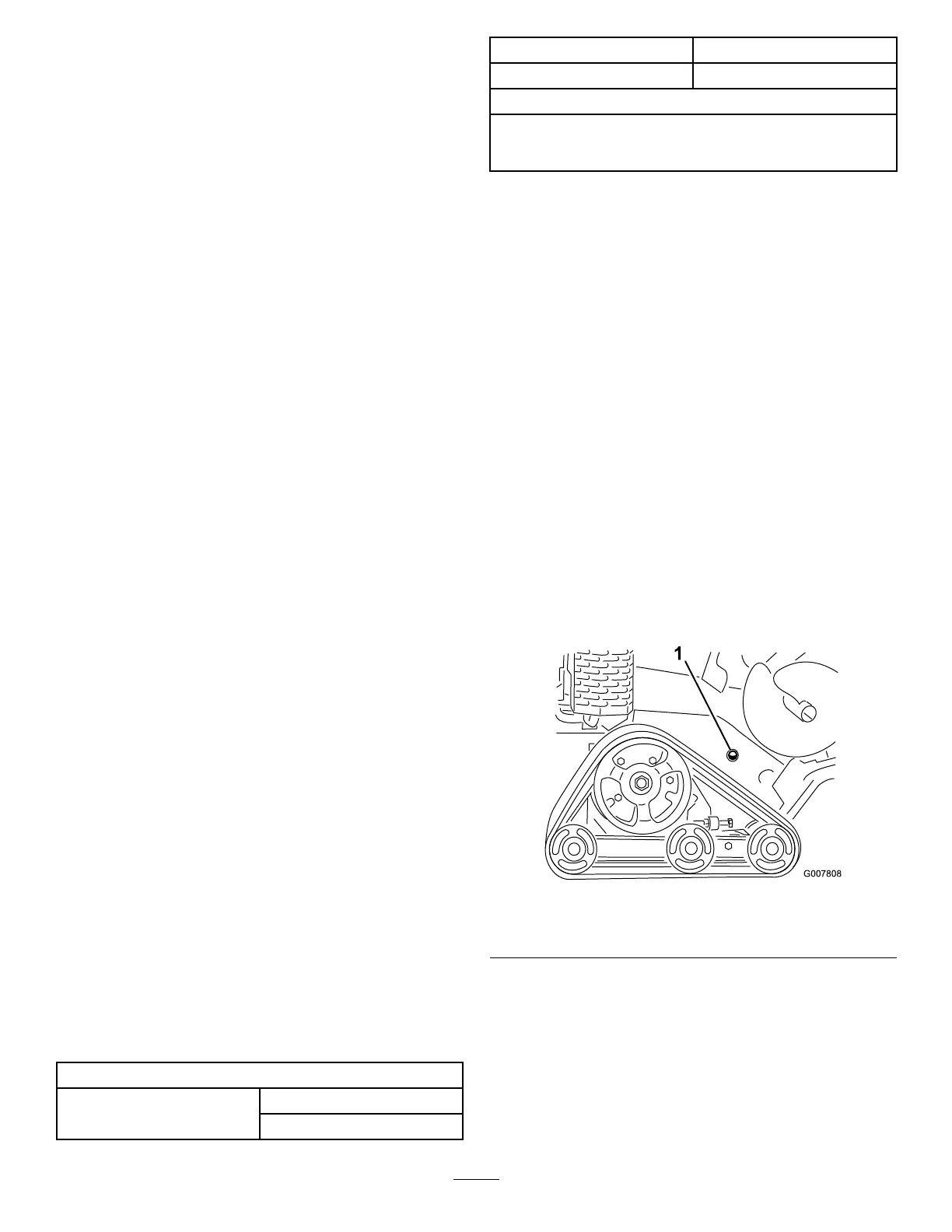

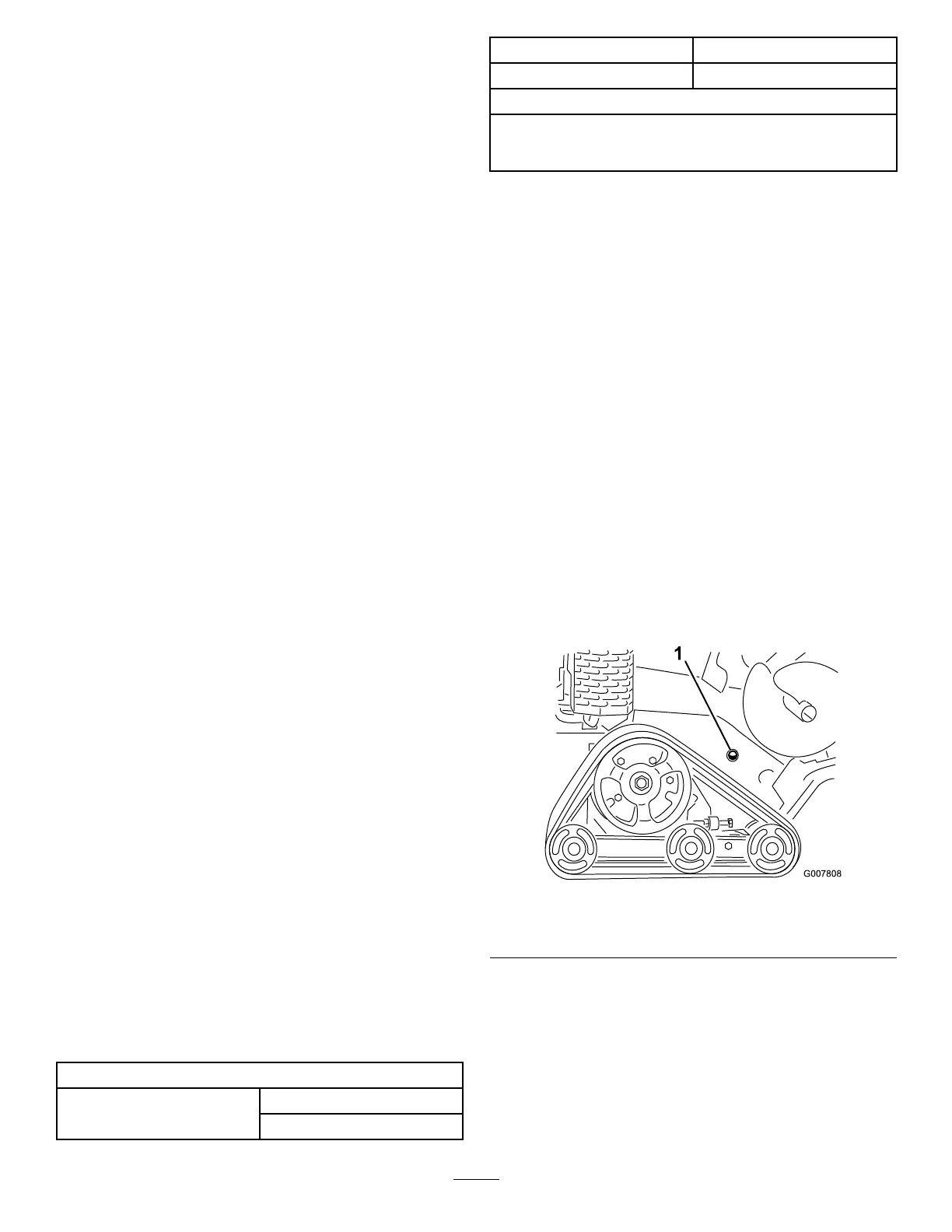

g007808

Figure 53

1. Hydraulic-uid check bubble

4. Remove the cover plate; refer to Removing the

Cover Plate ( page 21 ) .

5. Clean the area around the ller neck of the

hydraulic tank and remove the cap and lter

from the ller neck using a socket ( Figure 54 ).

37

Loading...

Loading...