the hydraulic uid to drain from the hose and

tank into the pan.

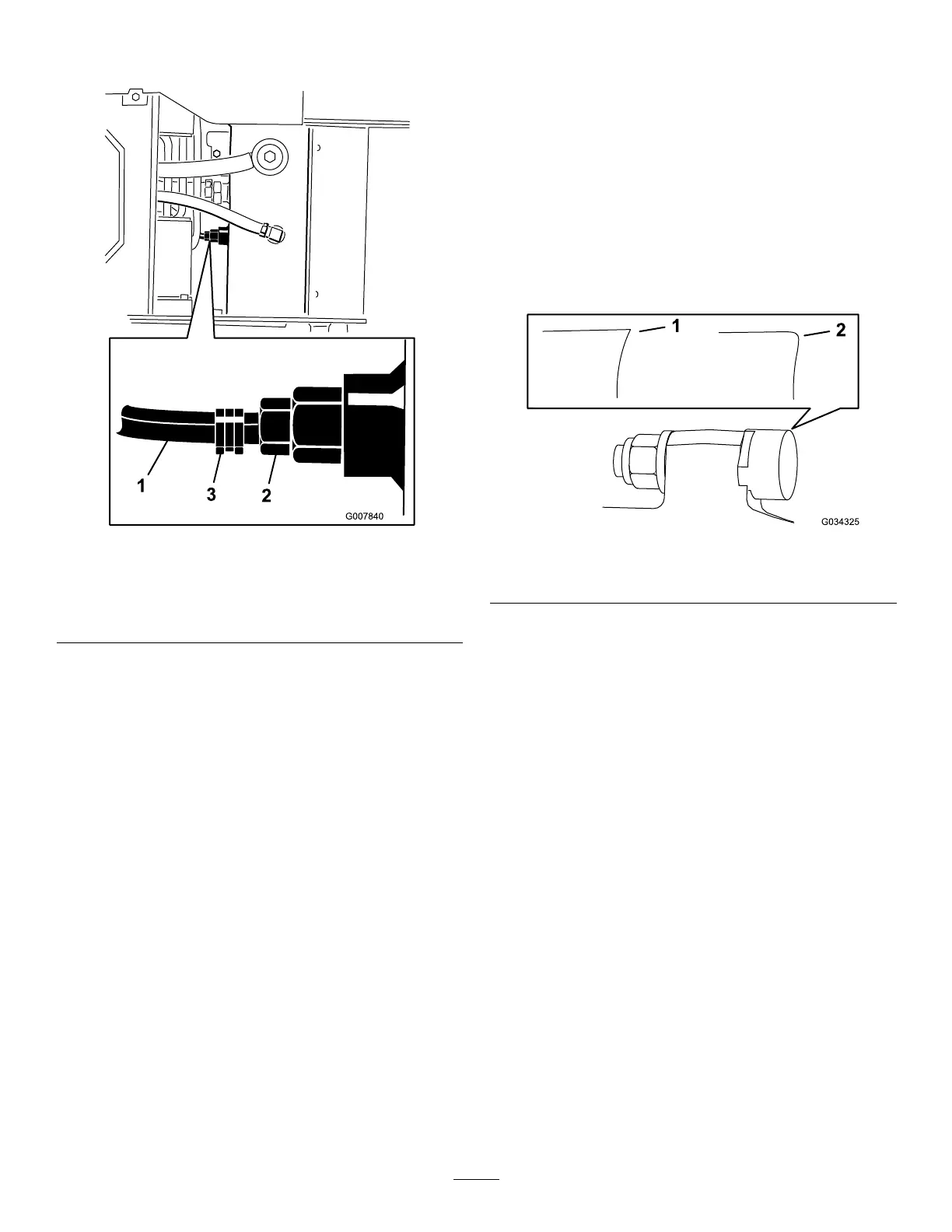

g007840

Figure 56

1. Hose

2. Hydraulic-tank tting

3. Hose clamp

8. When nished, install the hose onto the tting

and secure it with the hose clamp.

Note: Dispose of the used oil at a certied

recycling center .

9. Fill the hydraulic tank with hydraulic uid; refer

to Hydraulic Fluid Specications ( page 37 ) .

10. Install the hydraulic lter and ller cap ( Figure

54 ) and torque the bolt on top to 13 to 15.5 N∙m

(1 10 to 140 in-lb).

1 1. Start the engine and let it run for a few minutes.

12. Shut of f the engine.

13. Check the hydraulic-uid level and top it of f if

necessary; refer to Checking the Hydraulic-Fluid

Level ( page 37 ) .

14. Clean up any spilled uid.

15. Install the top cover .

Grinder Maintenance

Replacing the T eeth

Service Interval : Before each use or daily —Check

the condition of the teeth; rotate

or replace any that are worn or

damaged and torque the nuts for all

teeth.

Due to the high amount of wear placed on the teeth,

you need to rotate and replace them periodically

( Figure 57 ).

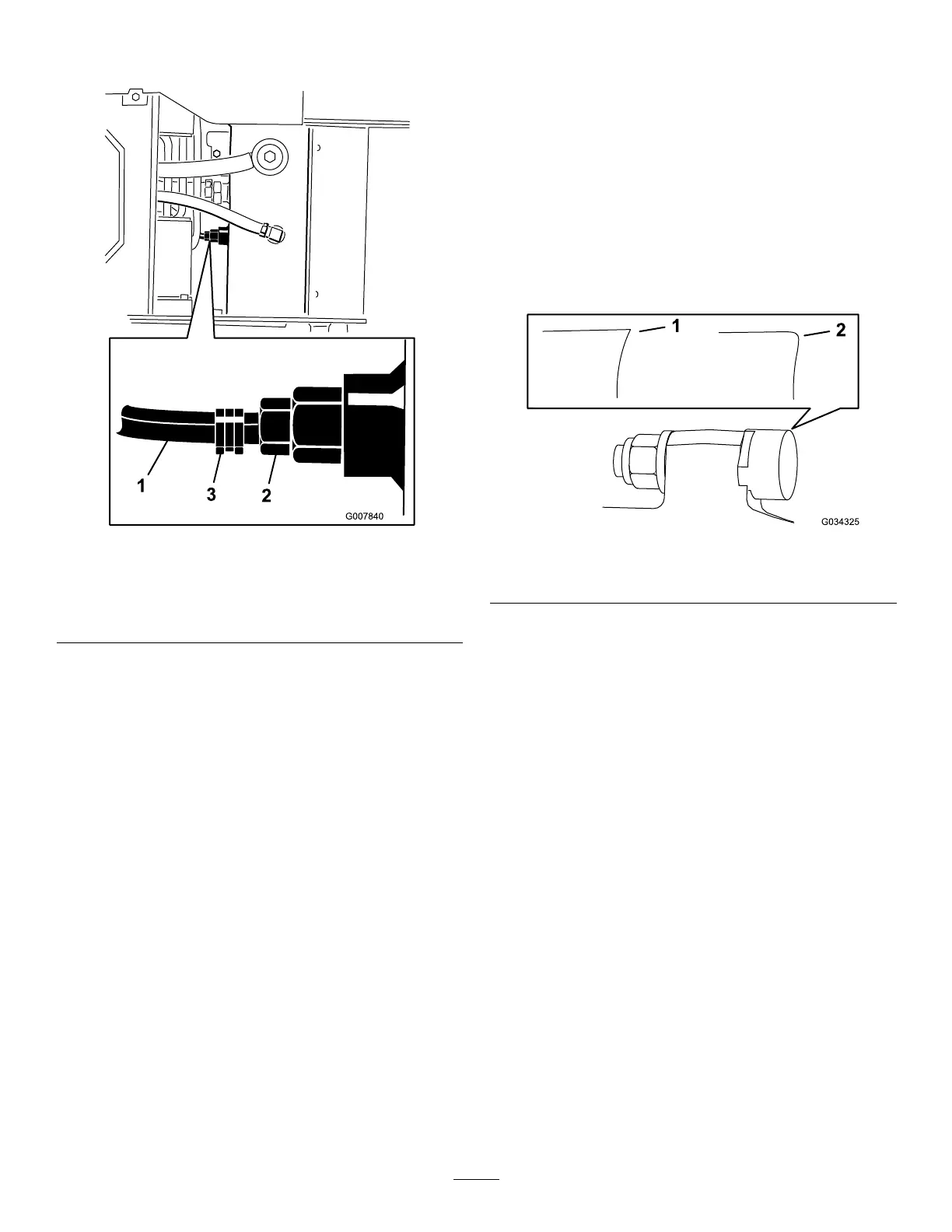

g034325

Figure 57

1. Sharp tooth

2. W orn tooth

Each tooth is indexed with 3 positions so you can

rotate it twice, exposing a new sharp edge before

replacing the tooth. T o rotate a tooth, loosen the nut

securing the tooth ( Figure 58 ). Push the tooth forward

and rotate it one third of a turn, bringing an unused

edge to the outside. T orque the nut securing the tooth

to 68 N∙m (50 ft-lb).

T o replace a tooth, remove the nut securing the tooth

to remove it, then install a new tooth, spacer , and

nut in the same position ( Figure 58 ). T orque the nut

securing the tooth to 68 N∙m (50 ft-lb).

39

Loading...

Loading...