7.Applyathincoatofspecieduidontotheseal

ofthenewtransmissionlter.

8.Installthelterbyrotatingitclockwiseontothe

lteradapteruntilthesealcontactsthebaseof

theadapter,thentightenthelteranadditional

3/4to1turn(Figure65).

9.Installthelterguardwiththe3washer-head

bolts(1/4x3/4inch)thatyouremovedinstep3

(Figure65),andtightentheboltsto1117to1243

N∙cm(90to110in-lb).

FillingtheTransmissionswith

Fluid

ServiceInterval:Aftertherst100hours

Every250hoursthereafter

1.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowthedrivewheelstoturnfreely.

CAUTION

Raisingthemachineforservice

ormaintenancerelyingsolelyon

mechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,

whichcouldcauseinjury.

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

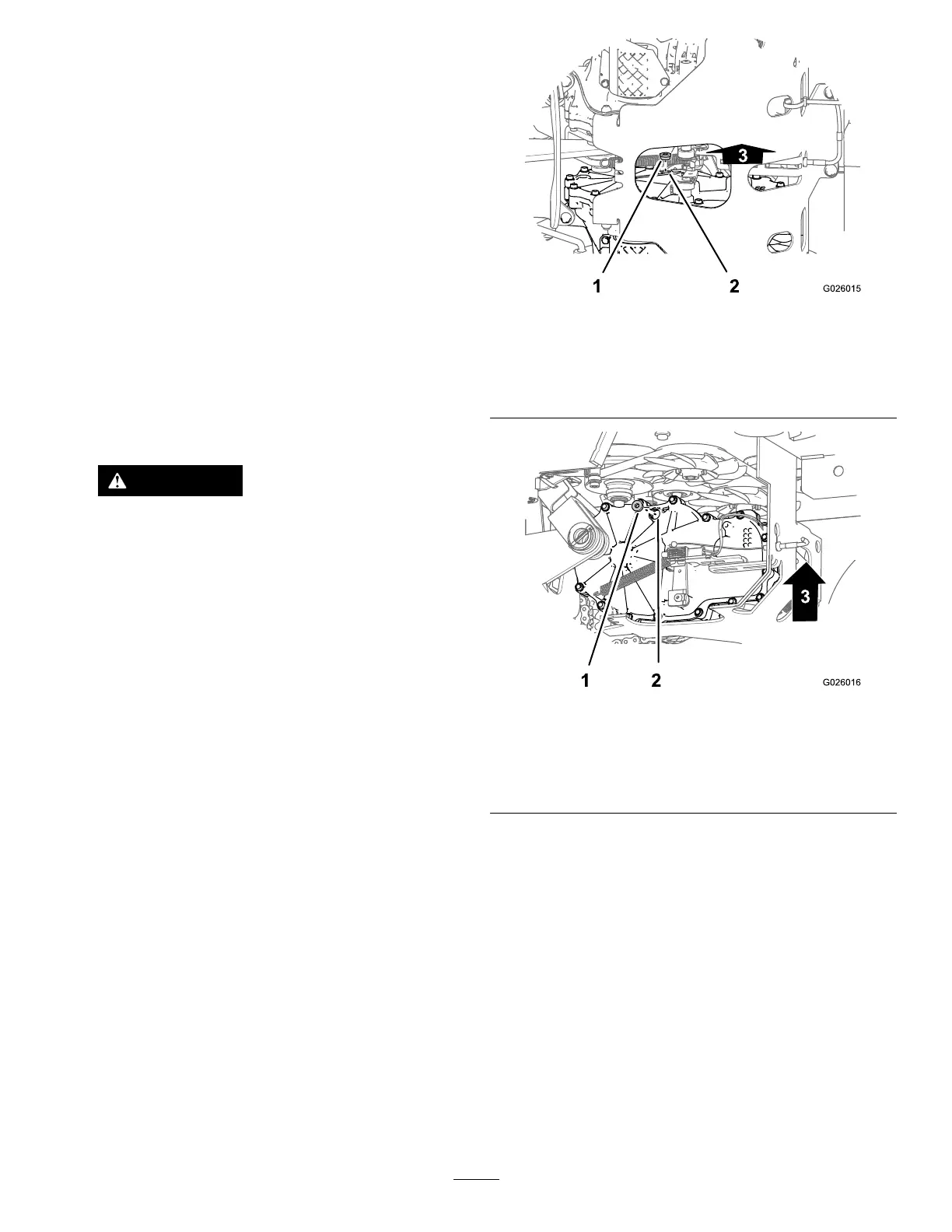

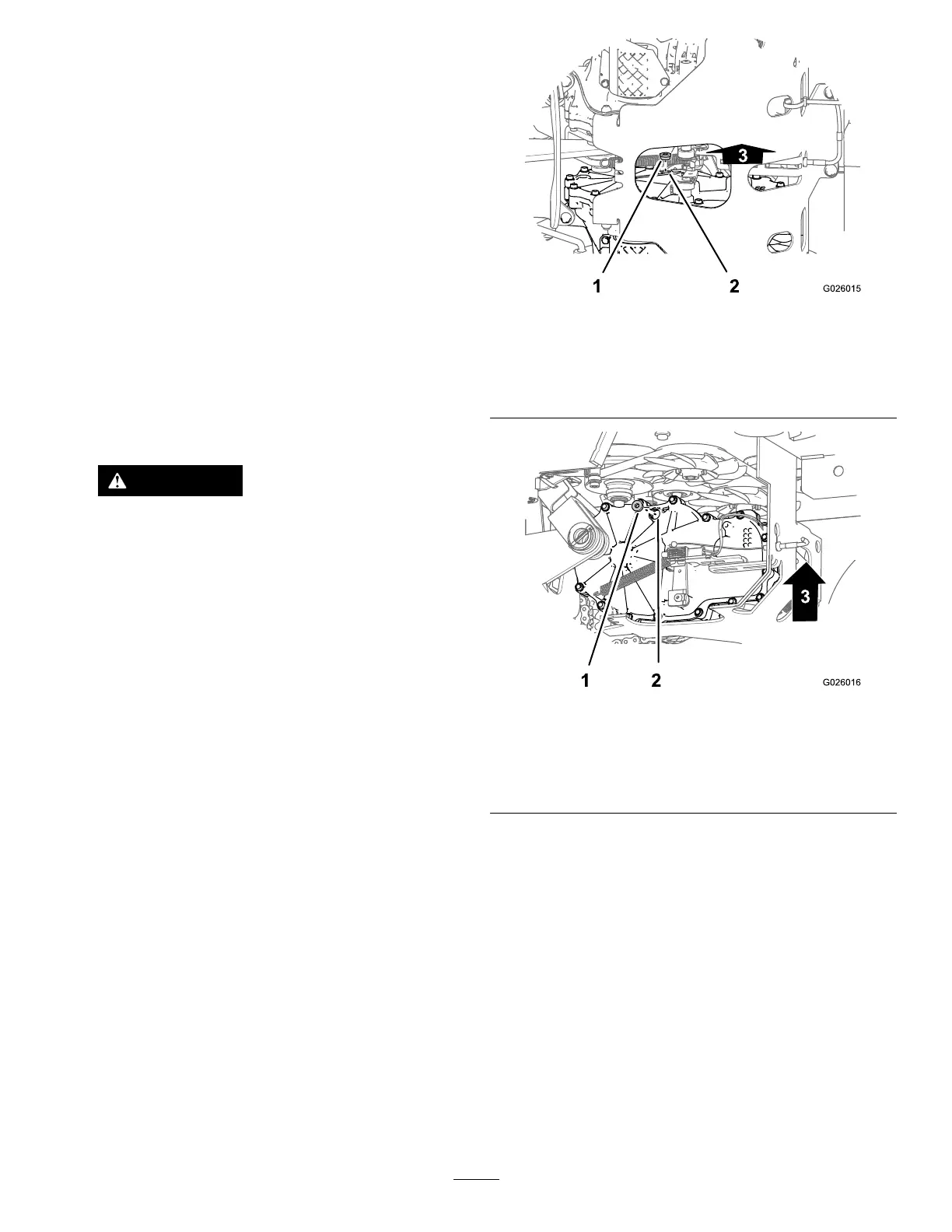

2.Alignadrainpanunderthesightplugsofthe

transmissions(Figure66andFigure67).

g026015

Figure66

Lefttransmissionshown

1.Sightplug

3.Up

2.Sight-plugport

g026016

Figure67

Lefttransmissionshown

1.Sightplug

3.Up

2.Sight-plugport

3.Attheinboardsideofthetransmission,near

thetop,removethesightplugfrom1ofthe

transmissions(Figure66andFigure67).

4.Addthespecieduidtotheexpansiontank

untiluidowsfromthesight-plugport;referto

CheckingtheTransmissionFluidLevel(page

53).

5.Installthesightplugandtorqueitto244N∙m

(180in-lb).

6.Repeatsteps3through5fortheother

transmission.

7.Addthespecieduidintotheexpansiontank

untiltheuidlevelisattheFullColdlineofthe

tank.

54

Loading...

Loading...