Adjusting the T racking

1. Disengage the blade-control switch (PT O).

2. Drive to an open at area, move the

motion-control levers to the N EUTRAL -L OCK

position.

3. Move the throttle midway between the F AST and

S LOW positions.

4. Move both motion-control levers all the way

forward until they both hit the stops in the T -slot.

5. Check which way the machine tracks.

6. Engage the parking brake, shut of f the engine,

and remove the key .

7. Adjust the stop plates as needed.

• If the machine tracks to the right, loosen the

bolts and adjust the left stop plate rearward

on the left T -slot until the machine tracks

straight ( Figure 74 ).

• If the machine tracks to the left, loosen the

bolts and adjust the right stop plate rearward

on the right T -slot until the machine tracks

straight ( Figure 74 ).

8. T ighten the stop plate ( Figure 74 ).

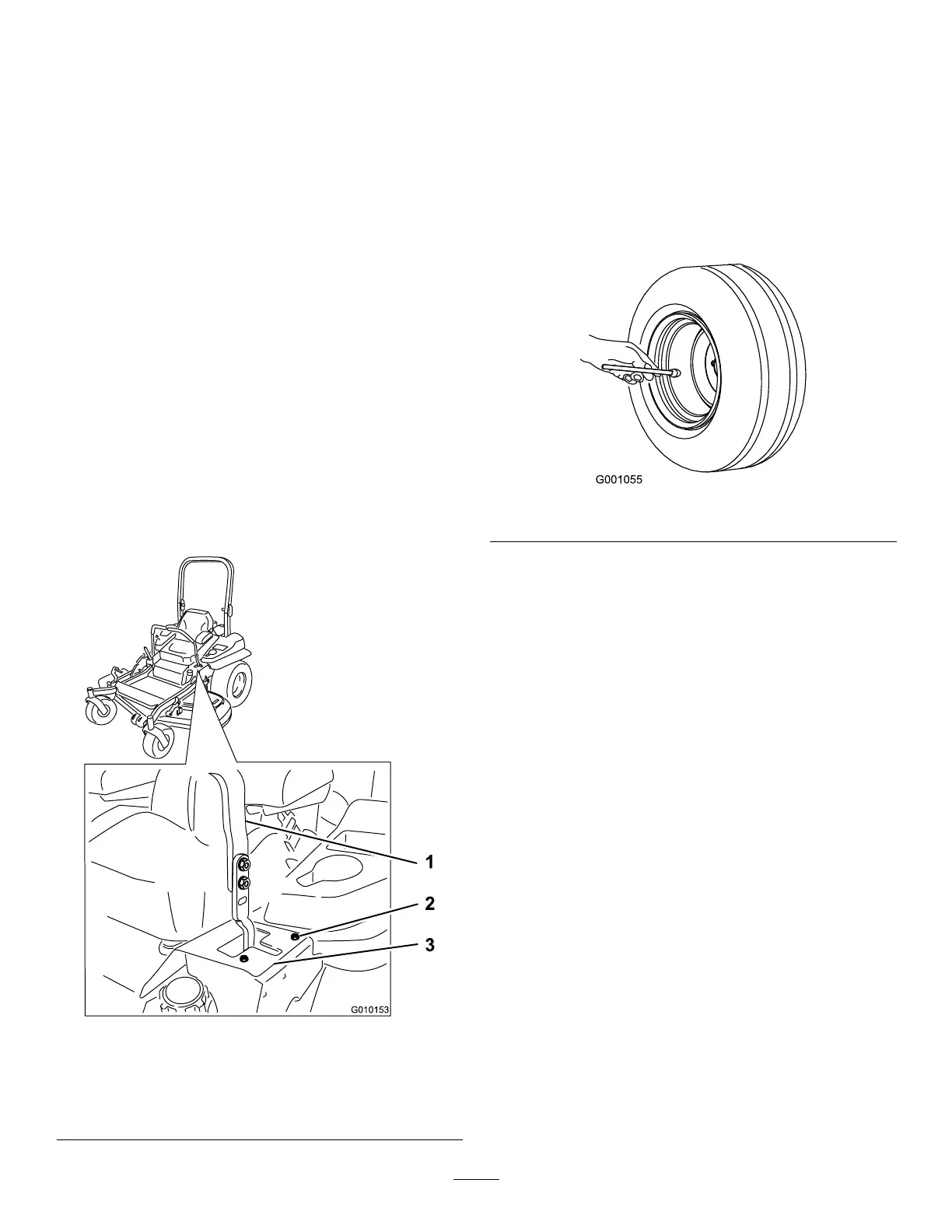

g010153

Figure 74

Left control lever shown

1. Control lever 3. Stop plate

2. Bolt

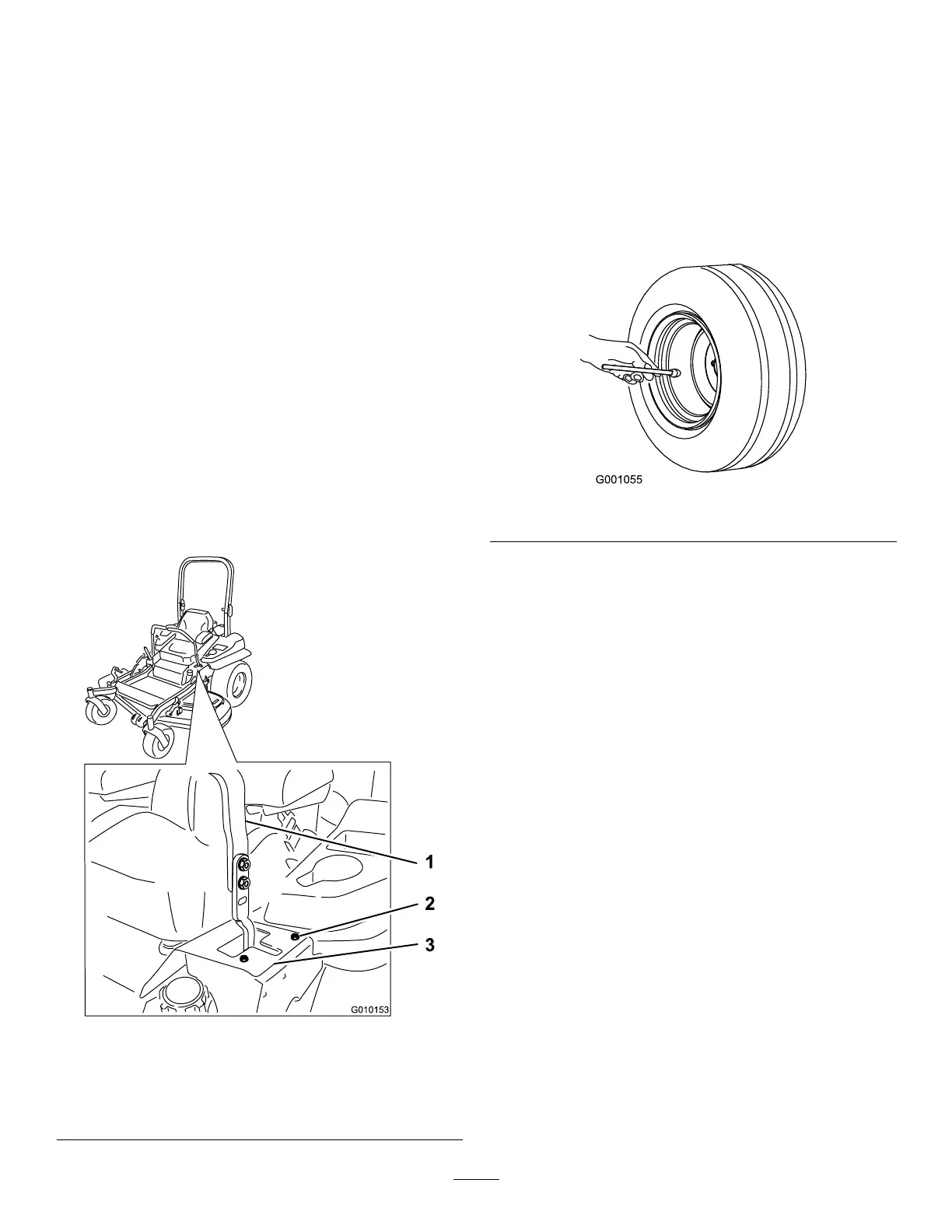

Checking the T ire Pressure

Service Interval : Every 50 hours/Monthly (whichever

comes rst)

Maintain the air pressure in the rear tires at 90 kPa

(13 psi). Uneven tire pressure can cause uneven cut.

Check the tires when they are cold to get the most

accurate pressure reading.

Note: The front tires are semi-pneumatic tires and do

not require air pressure maintenance.

g001055

Figure 75

Checking the Wheel Lug

Nuts

Check and torque the wheel lug nuts to 122 to 129

N∙m (90 to 95 ft-lb).

56

Loading...

Loading...