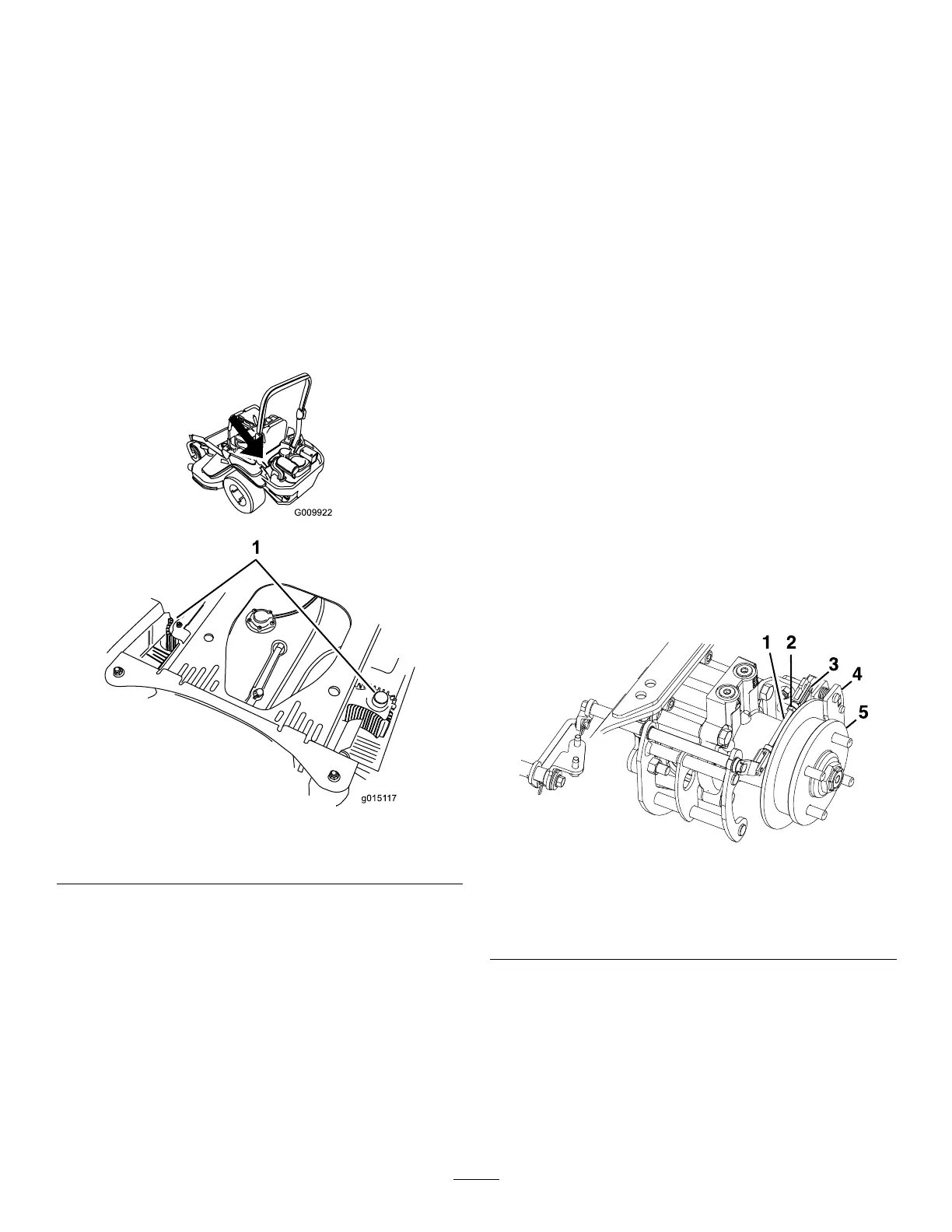

Checking and Cleaning the

Hydraulic-Unit Shrouds

Service Interval : Before each use or daily

1. Park the machine on a level surface, disengage

the blade-control switch (PT O), and engage the

parking brake.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. Move the seat forward.

4. Clean the debris and grass from the

hydraulic-unit shrouds ( Figure 95 ).

5. Position the seat.

g009922

g0151 17

Figure 95

1. Hydraulic-unit shrouds

Brake Maintenance

Adjusting the Parking

Brake

Service Interval : After the rst 100 hours

Every 500 hours

Check to ensure that parking brake is adjusted

properly . This procedure must be followed after the

rst 100 hours or when a brake component has been

removed or replaced.

1. Park the machine on a level surface, disengage

the blade-control switch, and engage the parking

brake.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. Raise the rear of the machine up and support

the machine with jack stands.

4. Remove the rear tires from the machine.

5. Remove any debris from the brake area.

6. Release the drive wheels; refer to Using the

Drive-Wheel-Release V alves ( page 36 ) .

7. Disengage the parking brake.

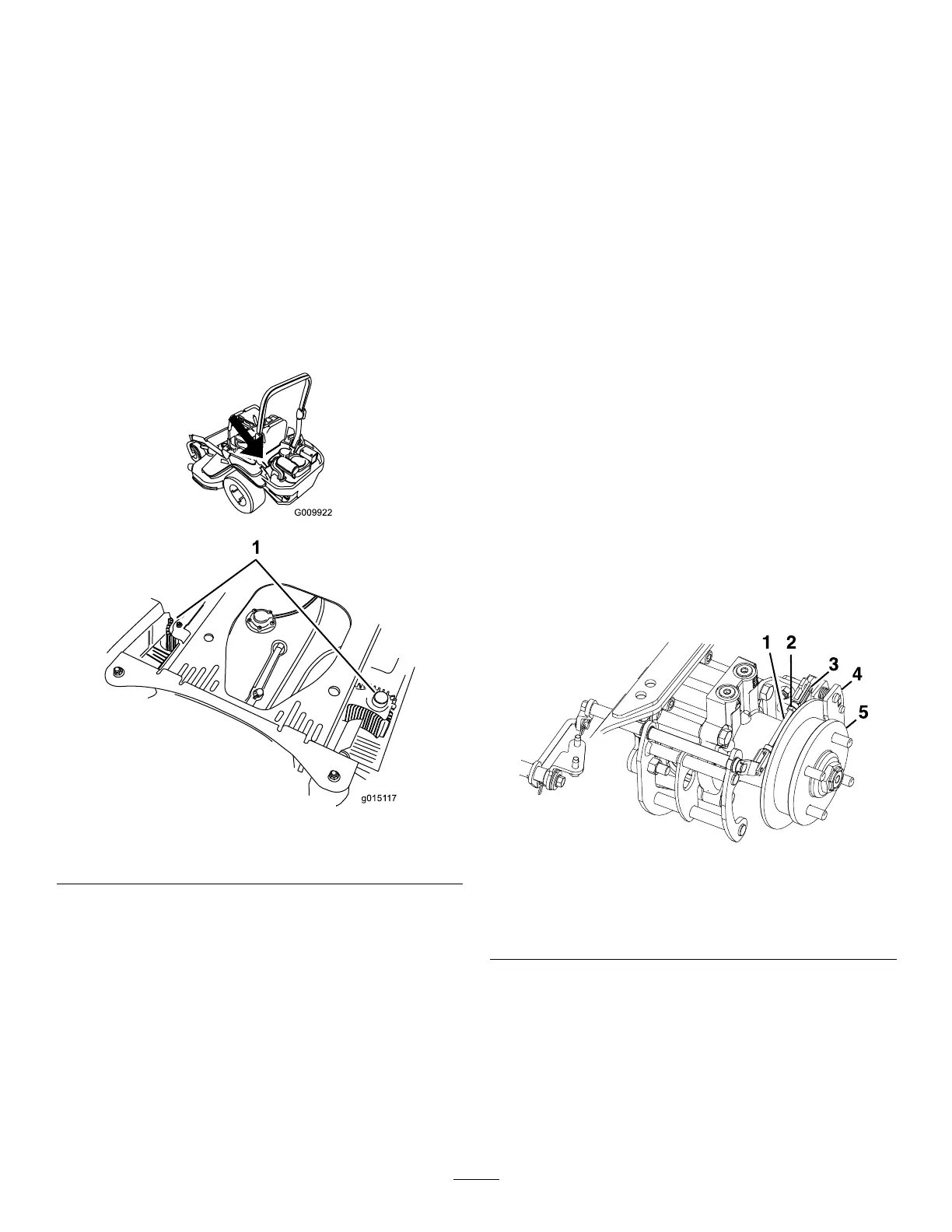

8. Remove the spring clevis pin from the rear

linkage and caliper ( Figure 96 ).

g297209

Figure 96

1. Rear linkage

4. Caliper

2. Jam nut 5. Wheel hub

3. Spring clevis pin

9. Loosen the jam nut on the rear linkage.

10. Push the caliper lever forward with nger

pressure until the brake pad contacts the hub

rotor .

1 1. Adjust the rear linkage until the spring clevis pin

can be inserted in the hole in the caliper lever .

Note: T o lengthen the linkage, rotate the clevis

1 turn outward.

66

Loading...

Loading...