ServicingtheCasterWheels

andBearings

Thecasterwheelsrotateonarollerbearingsupportedbya

spannerbushing.Ifthebearingiskeptwelllubricated,wear

willbeminimal.Failuretokeepthebearingwelllubricated

causesrapidwear.Awobblycasterwheelusuallyindicatesa

wornbearing.

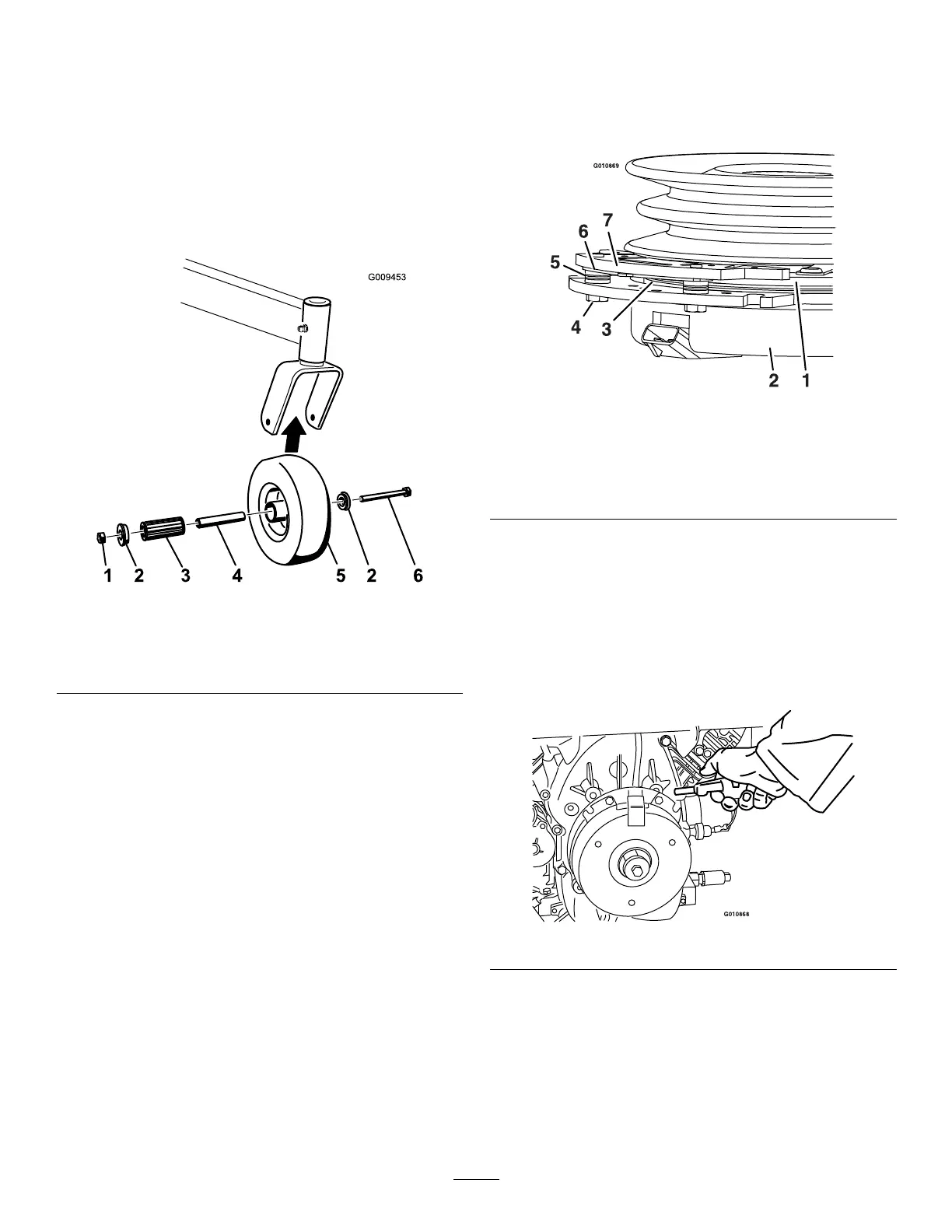

1.Removethelocknutandwheelboltholdingthecaster

wheeltothecasterfork(Figure57).

Figure57

1.Locknut4.Rollerbearing

2.Bushing

5.Casterwheel

3.Spannerbushing

6.Wheelbolt

2.Remove1bushing,thenpullthespannerbushingand

rollerbearingoutofthewheelhub(Figure57).

3.Removetheotherbushingfromthewheelhuband

cleananygreaseanddirtfromthewheelhub(Figure

57).

4.Inspecttherollerbearing,bushings,spannerbushing

andtheinsideofthewheelhubforwear.

Note:Replaceanydamagedorwornparts(Figure57).

5.Place1bushingintothewheelhub(Figure57).

6.Greasetherollerbearingandspannerbushing,and

slidethemintothewheelhub(Figure57).

7.Placethesecondbushingintothewheelhub(Figure

57).

8.Installthecasterwheelintothecasterforkandsecure

itwiththewheelboltandlocknut(Figure57).

9.Tightenthelocknutuntilthespannerbushingbottoms

againsttheinsideofthecasterforks(Figure57).

10.Greasethettingonthecasterwheel.

UsingtheClutchShim

Somelatermodelyearunitshavebeenbuiltwithclutchesthat

containabrakeshim.Whentheclutchbrakehasworntothe

pointwheretheclutchnolongerengagesconsistently,you

canremovetheshimtoextendtheclutchlife.

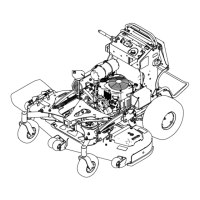

Figure58

1.Armature5.Brakespacer

2.Fieldshell6.Regaptheshim.

3.Rotor7.Brakepole

4.Brake-mountingbolt

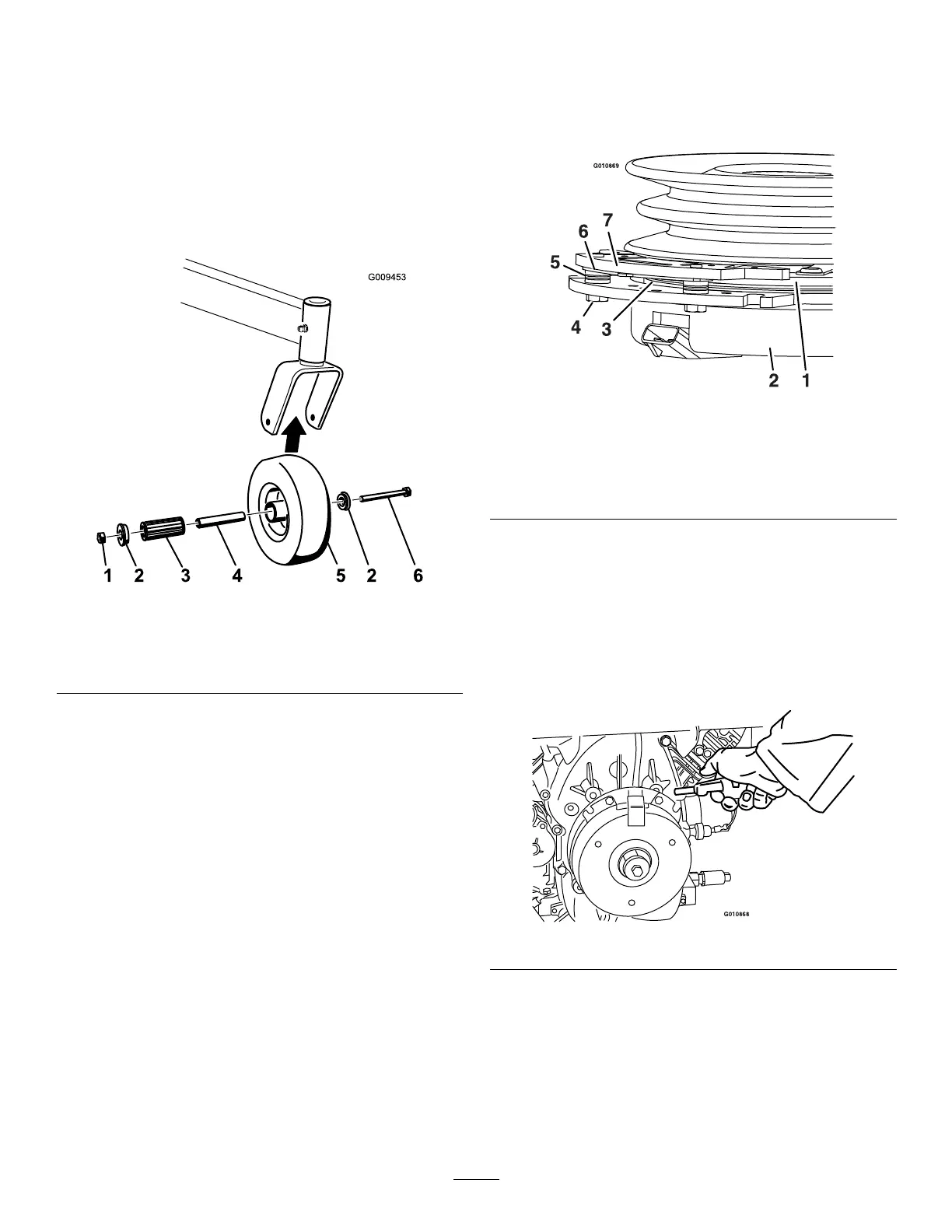

RemovingtheClutchShim

1.Shutofftheengine,waitforallmovingpartstostop,

andremovethekey.

2.Engagetheparkingbrakeandwaitformachinetocool

completely.

3.Usinganaircompressor,blowoutanydebrisunderthe

brakepoleandaroundthebrakespacers.

Figure59

4.Checktheconditionofthewire-harnessleads,

connectors,andterminals.Cleanorrepairthemas

necessary.

5.Verifythat12Vispresentattheclutchconnector

whentheyouengagetheblade-controlswitch(PTO).

6.Measurethegapbetweentherotorandarmature.If

thegapisgreaterthan1mm(0.04inch),proceedwith

thefollowingsteps:

41

Loading...

Loading...