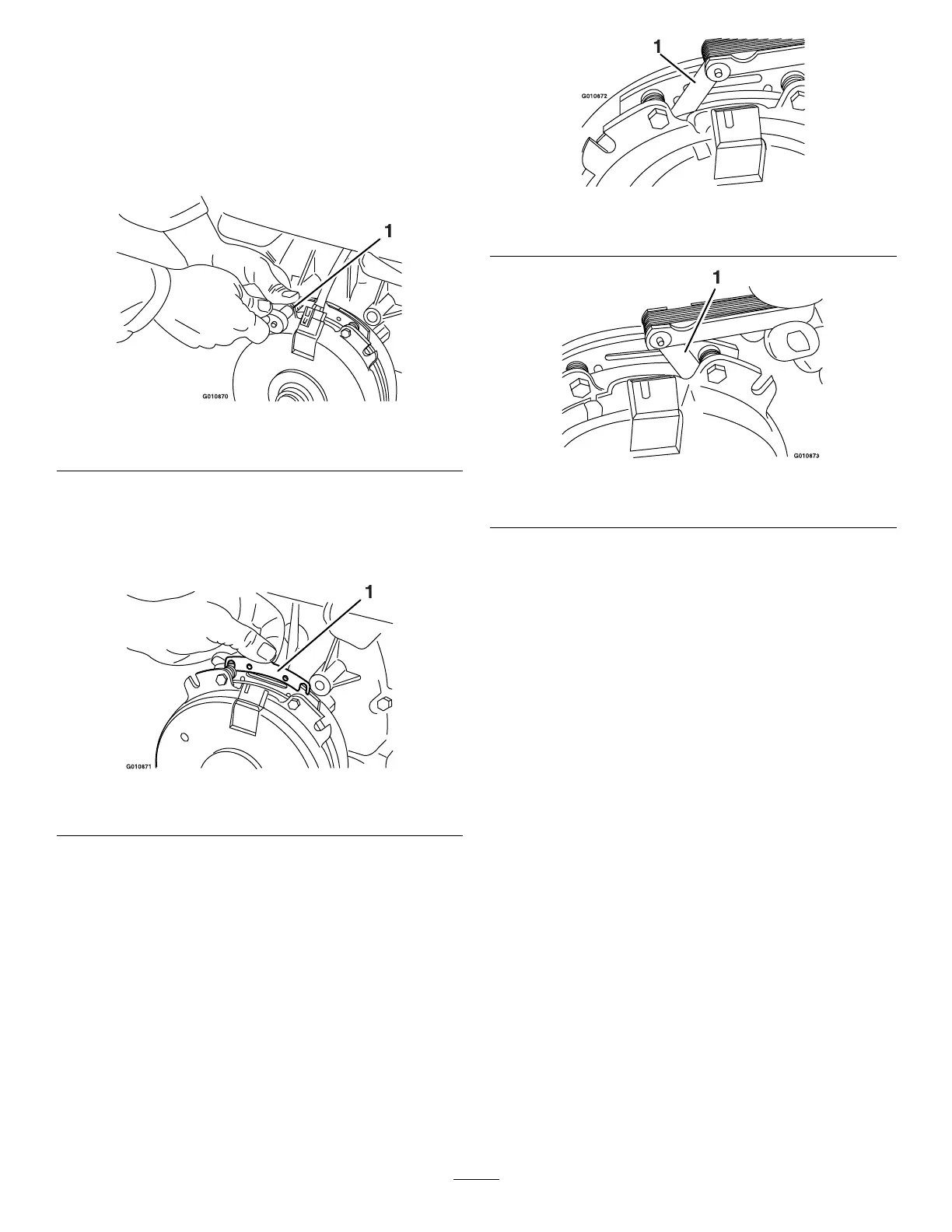

A.Loosenbothbrakemountingbolts1/2to1full

turnasshowninFigure60.

Note:Donotremovethebrakepolefromthe

eldshell/armature.Thebrakepolehasworn

tomatchthearmatureandneedstocontinueto

matchafteryouremovetheshimtoensurethe

properbraketorque.

Figure60

1.Brake-mountingbolt

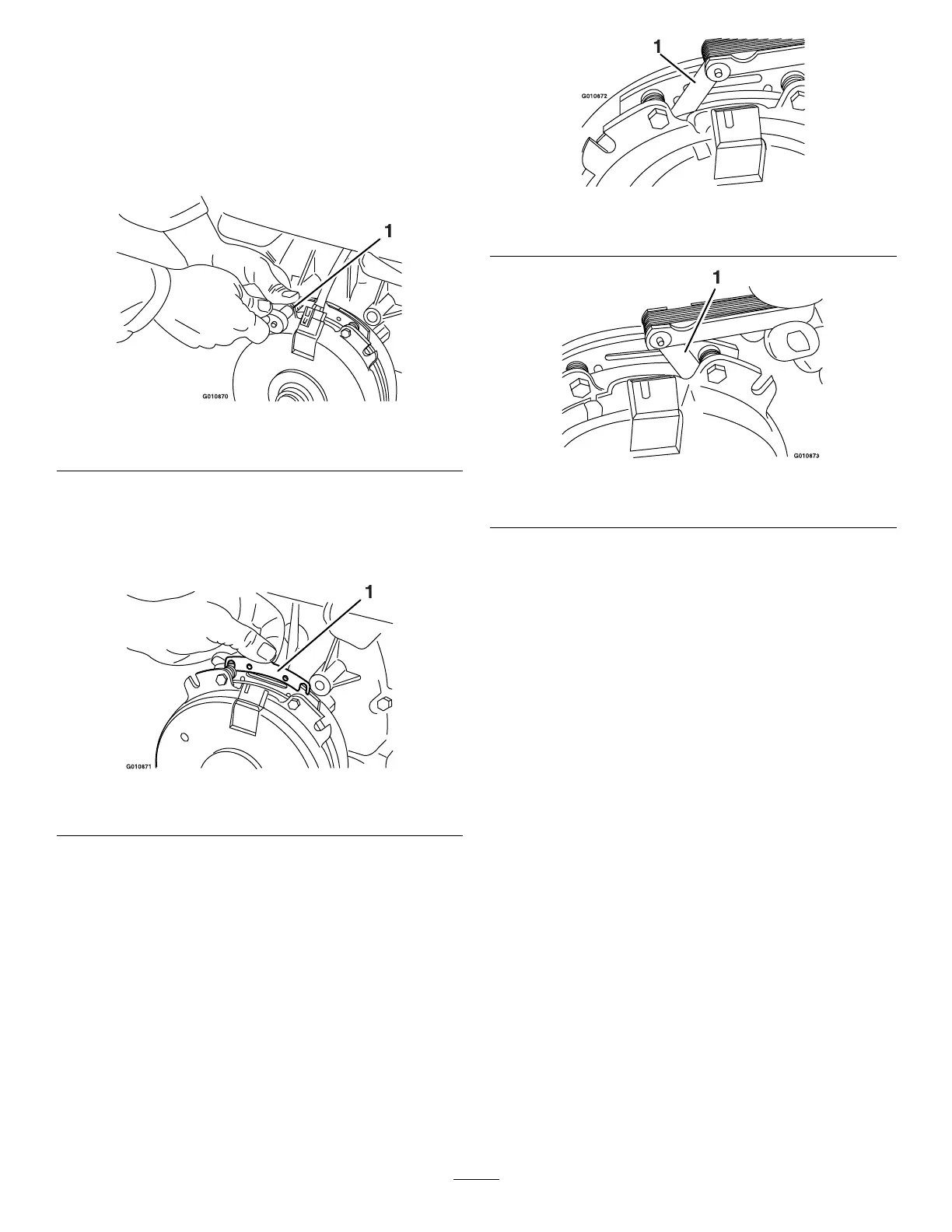

B.Usingneedle-nosepliers,orbyhand,removethe

shim.

Note:Donotdiscardtheshimuntilyouconrm

thattheclutchfunctionsproperly.

Figure61

1.Shim

C.Usingapneumaticline,blowoutanydebrisunder

thebrakepoleandaroundthebrakespacers.

D.Torqueeachbolt(M6x1)to12.3to13.7N∙m

(9.5to10.5ft-lb).

E.Usinga0.010inchthick-feelergauge,verifythat

agapispresentbetweentherotorandarmature

faceonbothsidesofthebrakepoleasshownin

Figure62andFigure63.

Note:Duetothewaytherotorandarmature

faceswear(peaksandvalleys),itissometimes

difculttomeasurethetruegap.

Figure62

1.Feelergauge

Figure63

1.Feelergauge

•Ifthegapislessthan0.010inch,theninstall

theshimandreferto(page).

•Ifthegapissufcient,proceedtothesafety

checkinstepF.

F.Performthefollowingsafetycheck:

i.Sitontheseatandstarttheengine.

ii.Makesurethatthebladesdonotengage

whentheblade-controlswitch(PTO)

isintheOFFpositionandtheclutchis

disengaged.

Note:Iftheclutchdoesnotdisengage,

installtheshim,andreferto(page).

iii.Engageanddisengagetheblade-control

switch(PTO)10consecutivetimesto

ensurethattheclutchisfunctioning

properly.

Note:Iftheclutchdoesnotengage

properly,referto(page).

42

Loading...

Loading...