Printed in the Federal Republic of Germany TR-Electronic GmbH 2007, All Rights Reserved

03/11/2016 TR - ECE - BA - DGB - 0065 - 03 Page 51 of 68

6 Commissioning

6.1 CAN interface

The CAN field bus interface (separated via optoelectronics with CAN-BUS-Driver

PCA82C250T) in the measuring system is determined according to the international

standard ISO/DIS 11898 and covers the two lower layers of the ISO/OSI reference

module.

The transformation of measuring system information into the CAN protocol occurs by

the protocol chip PCA82C200. The function of the protocol chip is monitored by a

watchdog.

The PREDEFINED MASTER/SLAVE CONNECTION SET is used for the measuring

system who only works as a slave. It will be used only the Group 2 Messages with

the exception of the Group 1 Message For Slave I/O Poll Response.

Establishing or breakdown of a connection must occur via Group 2 Only

Unconnected Explicit Request Message.

The measuring system contains an I/O Communication Port and an Explicit

Message Communication Port. The I/O communication port is used for polling the

measuring system position and must be made accessible by setting the watchdog

(after the I/O connection master/slave was set up before). Is the I/O port not

retriggered (polled) punctually the connection is interrupted and the red LED flashes.

The connection for the I/O port must be installed again.

During programming, data is exchanged between the measuring system and the

master in binary form.

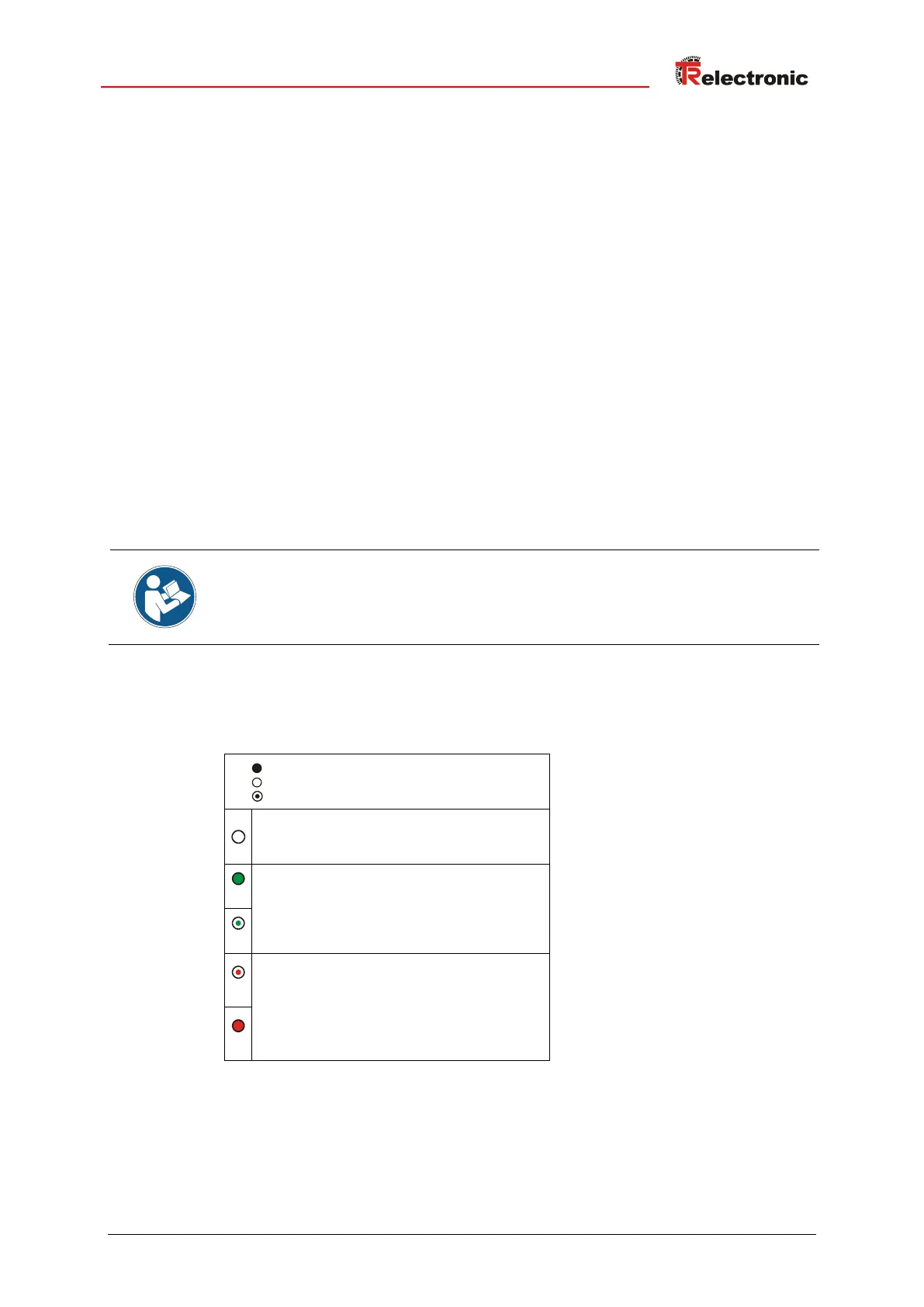

6.1.1 Bus status

Measuring system is not online

- no DUP-MAC-ID test

- Device may not be powered

Online, with connections in the established state

- Device is allocated to a master

DUP-MAC-ID test successful

- No allocation to a master

Recoverable faults

e.g. I/O-connections are in the time-out state

- Turn off system --> turn on system

- Replace measuring system device

Loading...

Loading...