8 BCXC-SVX01A-EN

Pre-Installation

ConsiderationsInstallation

Unit Location

Recommendations

When selecting and preparing the unit

installation location, consider the

following recommendations.

1. Consider the unit weight. Reference

the unit weight on the unit nameplate

or in the Dimensions and Weights

section on pages 9–10.

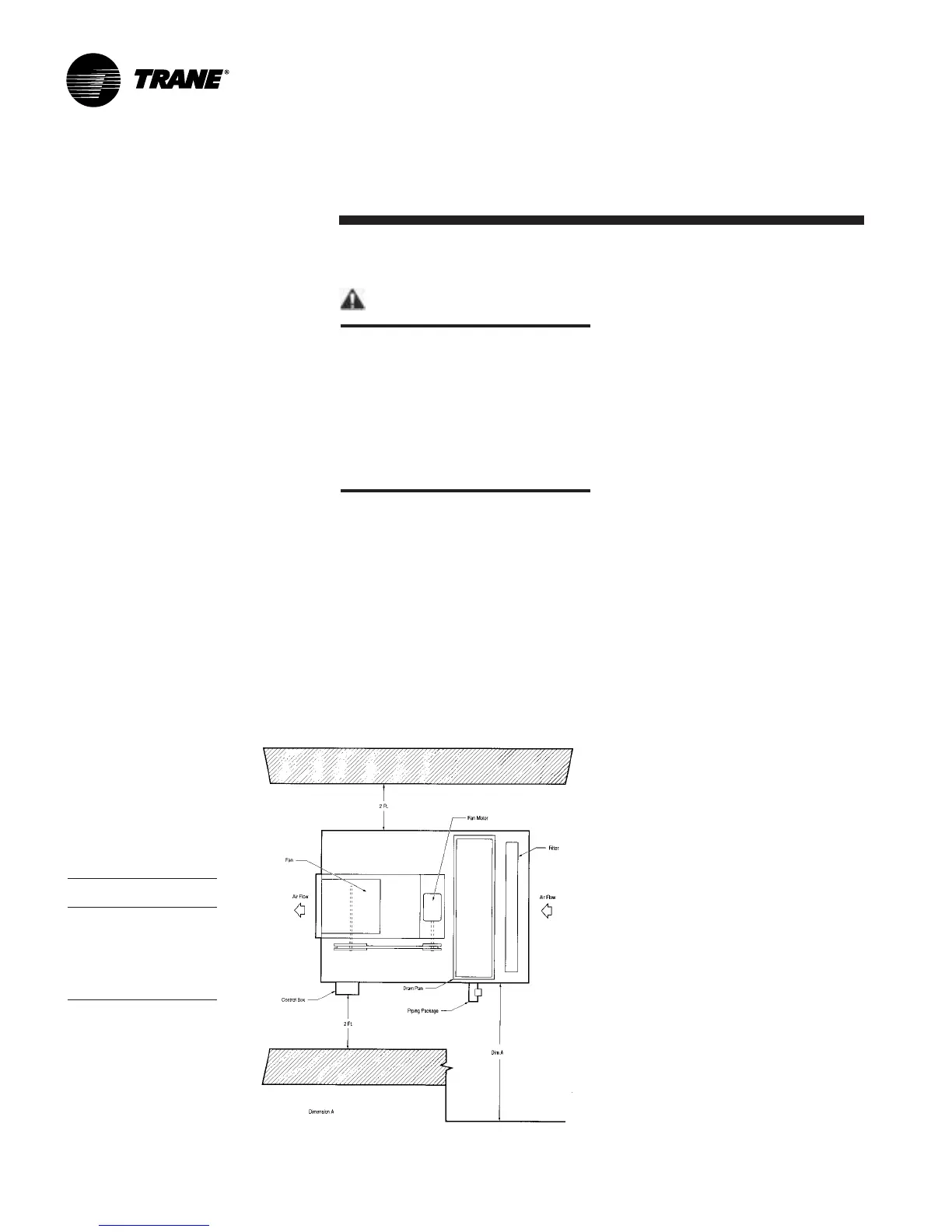

2. Allow sufficient space for the

recommended clearances, access

panel removal, and maintenance

access. Refer to Figure I-PC-1.

3. The installer must provide threaded

suspension rods for ceiling mounted

units. All units must be installed level.

4. Coil piping and condensate drain

requirements must be considered.

Allow room for proper ductwork and

electrical connections. Support all

piping and ductwork independently of

unit to prevent excess noise and

vibration.

Skid Removal

The unit ships on skids that provide

forklift locations from the front or rear.

The skid allows easy maneuverability of

the unit during storage and

transportation. Remove the skids before

placing the unit in its permanent location.

Remove the skids using a forklift or jack.

Lift one end of the unit off of the skids.

Vibration isolators for external isolation

are field supplied.

Pre-Installation Checklist

Complete the following checklist before

beginning unit installation.

!

Verify the unit size and tagging with

the unit nameplate.

!

Make certain the floor or foundation is

level, solid, and sufficient to support the

unit and accessory weights. Reference

unit and accessory weights on pages

9–14. Level or repair the floor before

positioning the unit if necessary.

!

Allow minimum recommended

clearances for routine maintenance

and service. Refer to unit submittals for

dimensions.

!

Allow one and one half fan diameters

above the unit for the discharge

ductwork.

WARNING

Improper Unit Lift!

Test lift the unit approximately 24

inches to verify proper center of

gravity lift point. To avoid dropping of

unit, reposition lifting point if unit is

not level. Failure to properly lift unit

can result in serious injury, possible

equipment or property-damage, or

death.

Unit Handling Procedure

1. Position rigging sling under wood skid

using spreader bars to avoid unit

damage.

2. Use a forklift with caution to prevent

unit damage. The fork length must be at

least 68 inches long to safely fork the unit

from front or back.

3. The unit center of gravity will fall within

the center of gravity block at various

locations depending on unit options.

4. See unit nameplate for unit weight.

Table I-PC-1. Service

Requirements, in. (cm)

Unit Size Dimension A

012 20 (50.8)

018 25 (63.5)

024 25 (63.5)

036 37 (94.0)

054 37 (94.0)

072 45(114.3)

090 45 (114.3)

Rigging and Handling

Before preparing the unit for lifting,

estimate the approximate center of

gravity for lifting safety. Because of

placement of internal components, the

unit weight may be unevenly distributed,

with more weight in the coil area.

Approximate unit weights are given in

the Dimensions and Weights section

beginning on page 9. Also, you may

reference the unit weight on the unit

nameplate.

Before hoisting the unit into position, use

a proper rigging method such as straps,

slings, or spreader bars for protection

and safety. Always test-lift the unit to

determine the exact unit balance and

stability before hoisting it to the installa-

tion location.

Figure I-PC-1. Top view of blower coil unit showing recommended service and code

clearances.

Loading...

Loading...