RT-SVX24Q-EN

207

Microchannel Condenser Coil

Repair and Replacement

If microchannel condenser coil repair or replacement is

required, refer to General Service Bulletin RT-SVB83*-

EN for further details.

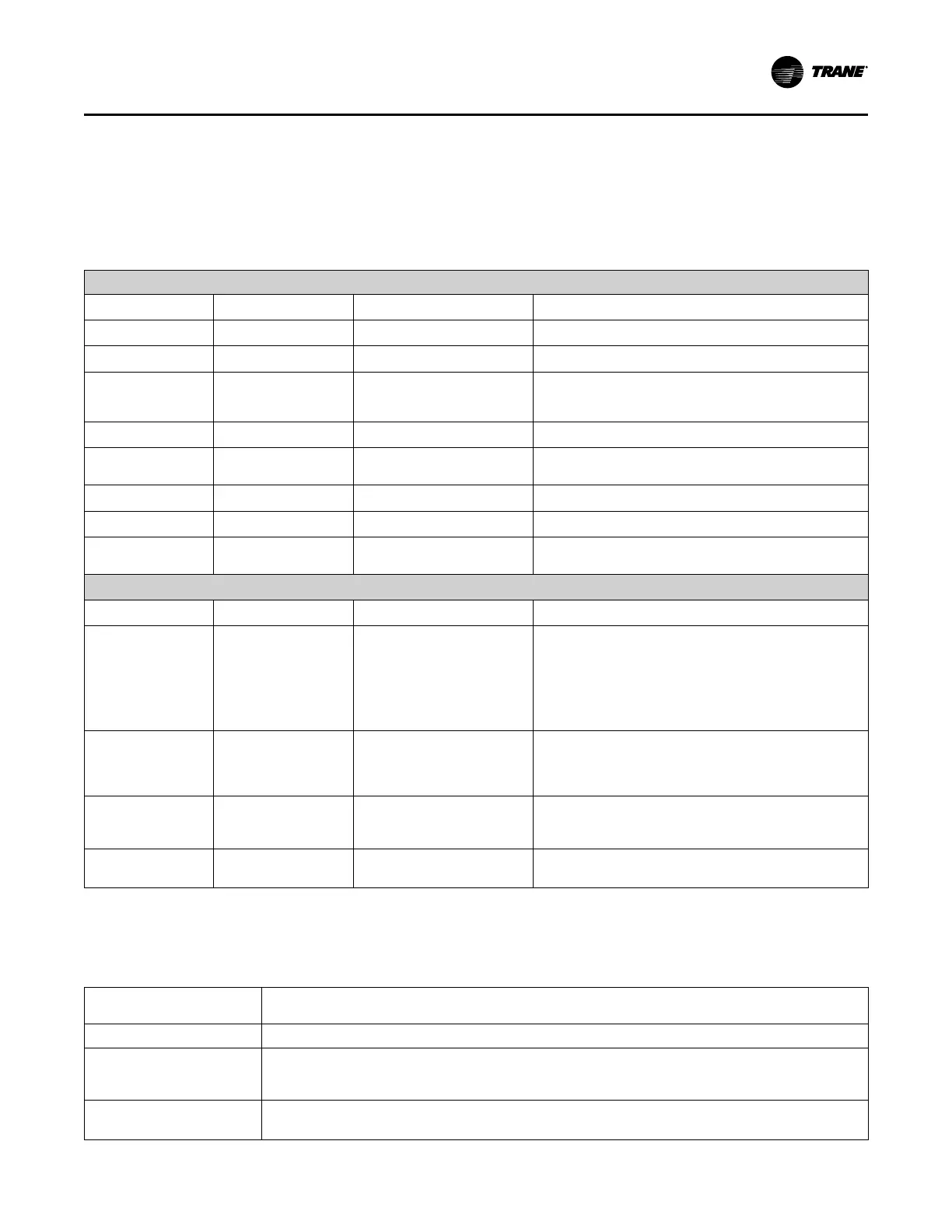

Table 79. Evaporative condenser models—maintenance and troubleshooting

Maintenance Schedule

Component

Action

Frequency

Comments

Fan Motor

None Required Non-grease bearings

Sump Pump Inspect / Clean 1 – 2 times per year Clean inlet openings to pump

Sump Inspect / Clean

1 – 2 times per year

depending on water hardness

and unit run time

Sump can be drained and hosed out using hose bib

provided at water fill solenoid valve. Vacuuming scale out is

an alternate method

Sump Float Switch Inspect 1 – 2 times per year

Float should be free for full float travel

Sump Float Make Up

Valve

Inspect for proper

water level

1 – 2 times per year

Spray Nozzles Inspect / Clean 1 – 2 times per year Inspection through access panel

Conductivity Sensor Inspect / Clean 1 – 2 times per year Clean sensor to ensure accurate readings

Conductivity

Controller

Inspect / Recalibrate 1 – 2 times per year

Recalibrate controller

Troubleshooting

Component

Problem Check Fix

Fan Motor Does not run

Condenser Fan Relay closure

and control voltage indicating

a call from compressor control

panel for the condenser fan to

operate. Sump Pump

Overload Trip. Fan Motor

Overload Trip. Fan fuse trip.

Check each motor overload and reset if necessary. Check

amp draw for each leg.

Sump Pump

Does not run

Sump Pump Overload Trip

Low Water Level or faulty float

switch. Unit in ‘Dry Mode’

Operation

Reset – check amps on each leg to determine if faulty

motor. Check and clean debris around float switch. Check

Ambient thermostat setting and mode of operation (close

on rise). See section 2 for T’stat setup instructions.

Sump Pump

Low Flow

Pump may be operating

backwards or impeller inlet

may be slightly blocked.

Change pumping direction by changing any two legs to the

pump motor. Disconnect Power and remove pump to

inspect for possible impeller obstruction.

Spray Nozzle Dry area on coil

Check for proper spray

pattern over each quadrant.

Remove debris from clogged nozzle.

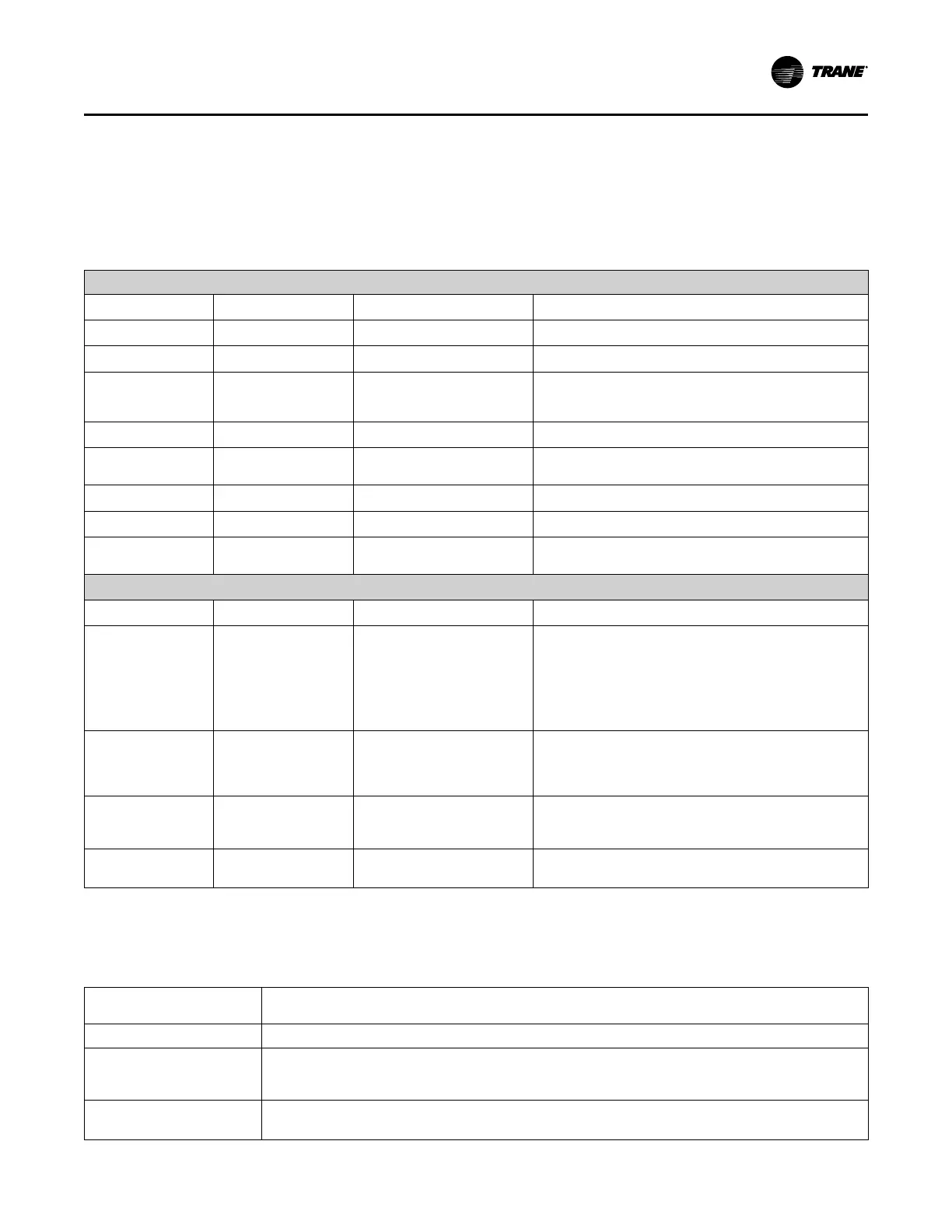

Final Process

Record the unit data in the blanks provided.

Table 80. Unit data log

Complete Unit Model

Number:

Unit Serial Number:

Unit “DL” Number

(“design special” units

only):

Wiring Diagram Numbers

(from unit control panel):

SSeerrvviiccee aanndd MMaaiinntteennaannccee

Loading...

Loading...