Maintenance

Section

4-13AB38 Work Platform

4.10

Every 500 working hours, or annually

Brushes - Check the wear, the correct seating,

and the regularity of the working

surface.

Springs - They should not be burned or

damaged, and they must apply a

constant and equal pressure on the

brushes.

Commutator - The surface must be clean and

regular without grooving or burning.

Every 1000 working hours, or every two years

Bearings- All the bearings are fitted with a

double shield and lubricated with

high temperature grease.

Check for leaks, vibration and noise.

If necessary replace with bearings

of identical type.

Screws - Check that all nuts, particularly the

cable nuts and screws are tight.

General - Check that foreign bodies or dirt

have not entered the motor.

Check that the ventilation holes are

clean and not obstructed.

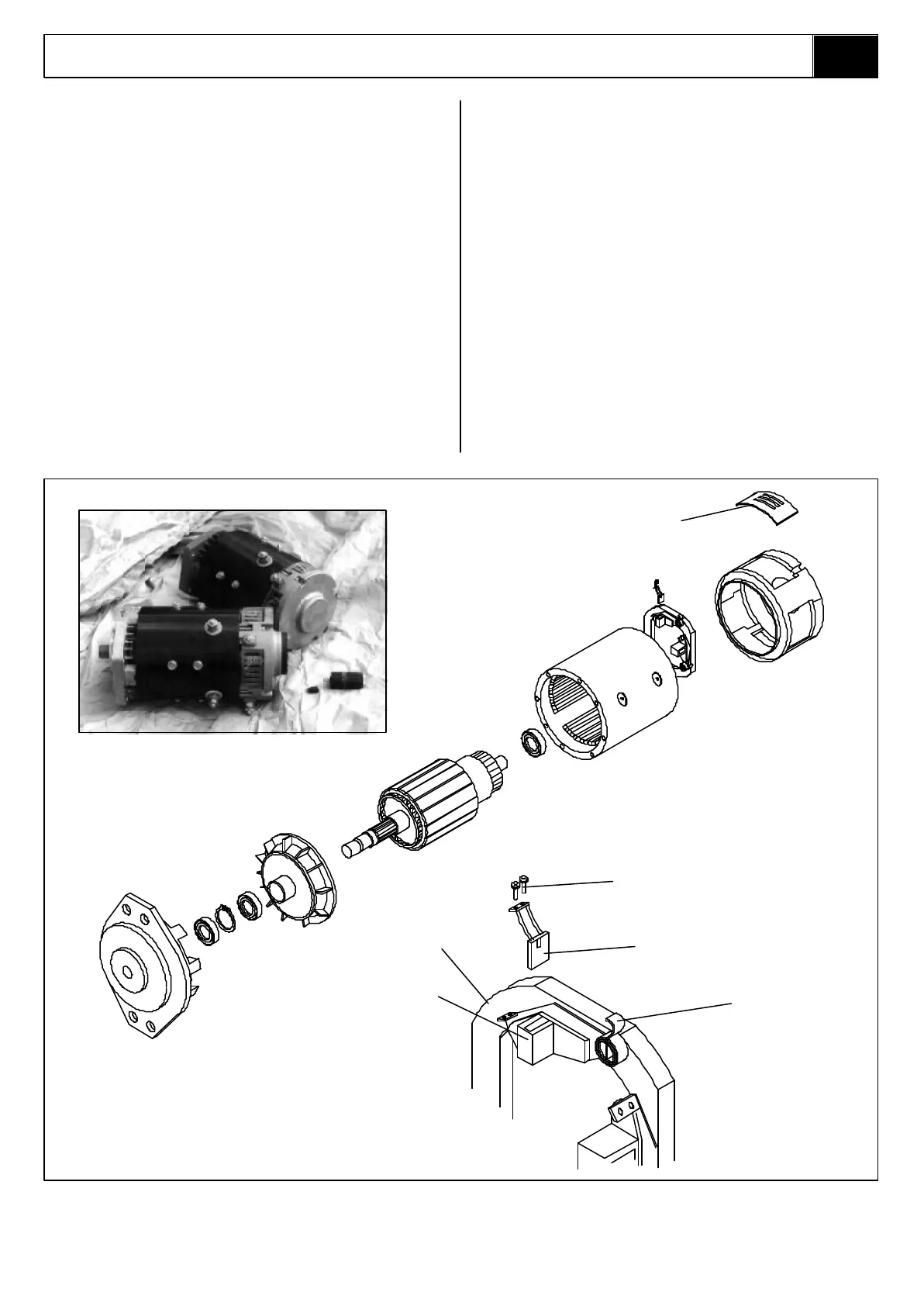

Figure 4-11: Traction Motor Maintenance

1. Brush

2. Bolt

3. Spring

4. Brush Box Support

5. Brush Box

6. Inspection/

Ventilation Cover

6

5

4

2

1

3

Loading...

Loading...