20 Installation and maintenance instructions 0020308121_04

7.2.6 Replacing the standard connector for the

air/flue pipe, where required

7.2.6.1 Removing the standard connector for the

air/flue pipe

7.2.6.2 Installing the connector for the air/flue pipe,

60/100 mm or 80/125 mm diameter

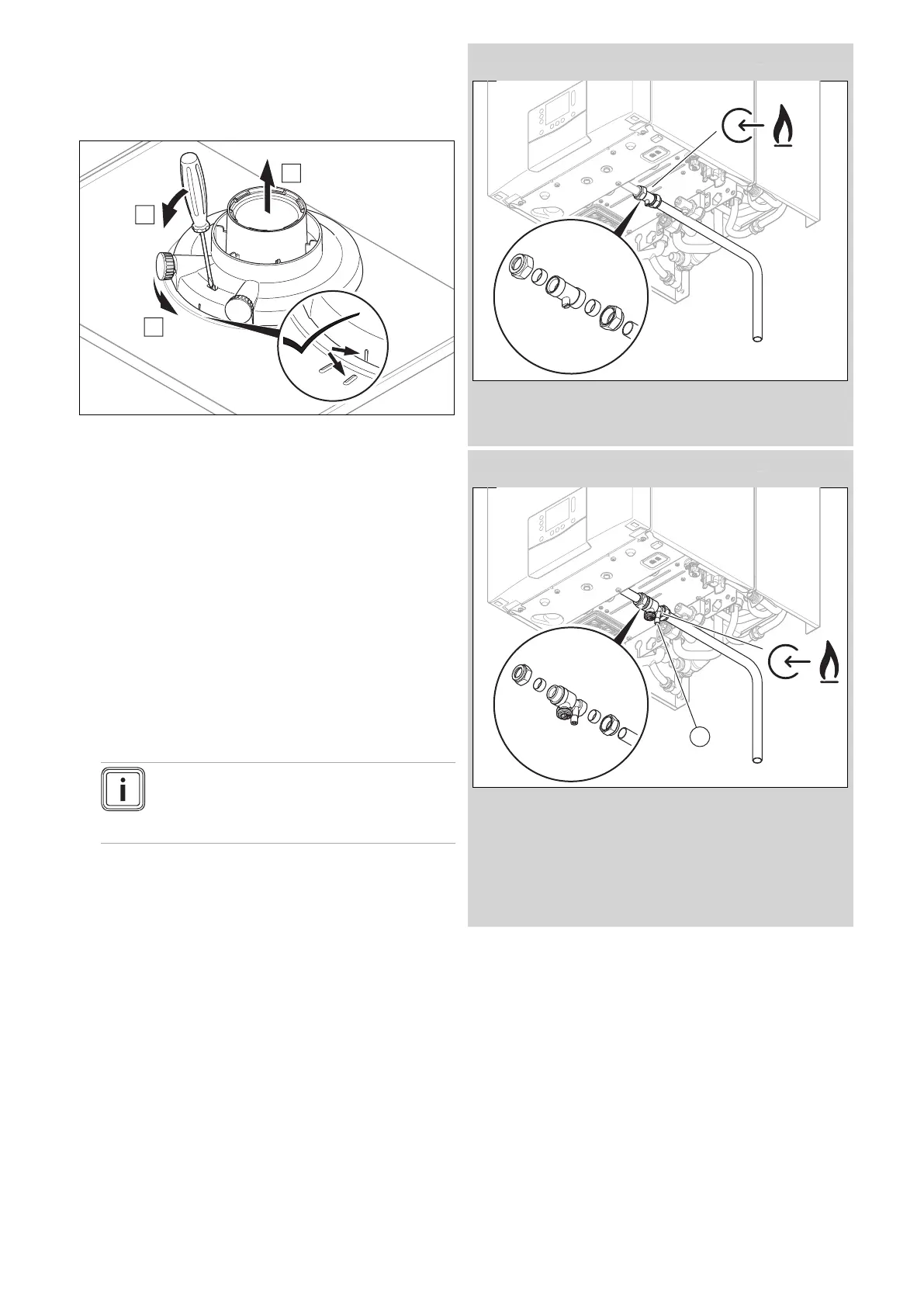

1. Remove the standard connector for the air/flue pipe.

(→ Section 7.2.6.1)

2. Insert the alternative connector. In doing so, pay atten-

tion to the latching lugs.

3. Turn the standard connector clockwise until it clicks

into position.

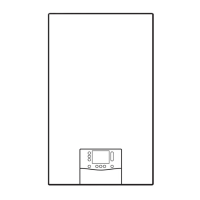

7.3 Installing the gas connection

▶ Install the gas pipe in accordance with the recognised

rules of technology.

▶ Remove the residues from the gas pipe by decoupling on

both sides and blowing through the gas pipe.

▶ Use the enclosed gas isolation valve. Observe the spe-

cified flow direction.

Note

Gas isolation valves with or without test nipple

are available in the dimensions 15 to 15 mm

or 22 to 15 mm.

Condition: Gas isolation valve without test nipple

▶ Connect the product to the gas pipe as shown in accord-

ance with the recognised rules of good engineering prac-

tice.

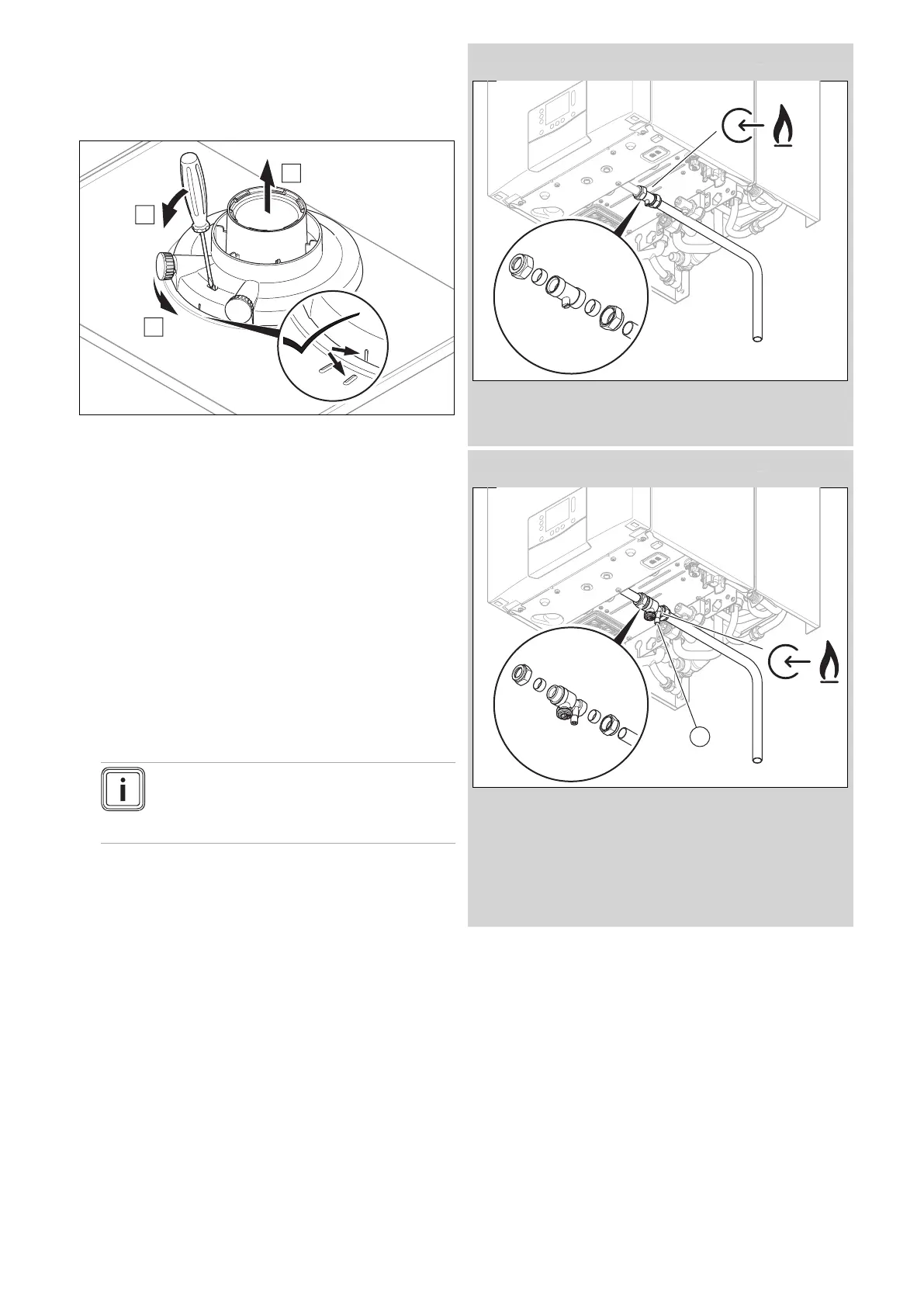

Condition: Gas isolation valve with test nipple (requirement for BS 6891)

▶ Connect the product to the gas pipe as shown in accord-

ance with the recognised rules of good engineering prac-

tice.

▶ Always ensure that the test nipple (1) is sealed and is

correctly checked for tightness. Tightening torque, see

appendix.

– Working materials: 3 mm hex key

▶ Purge the gas pipe before start-up.

▶ Check the entire gas supply for tightness in accordance

with the relevant standards.

Loading...

Loading...