78 Installation and maintenance instructions 0020308121_04

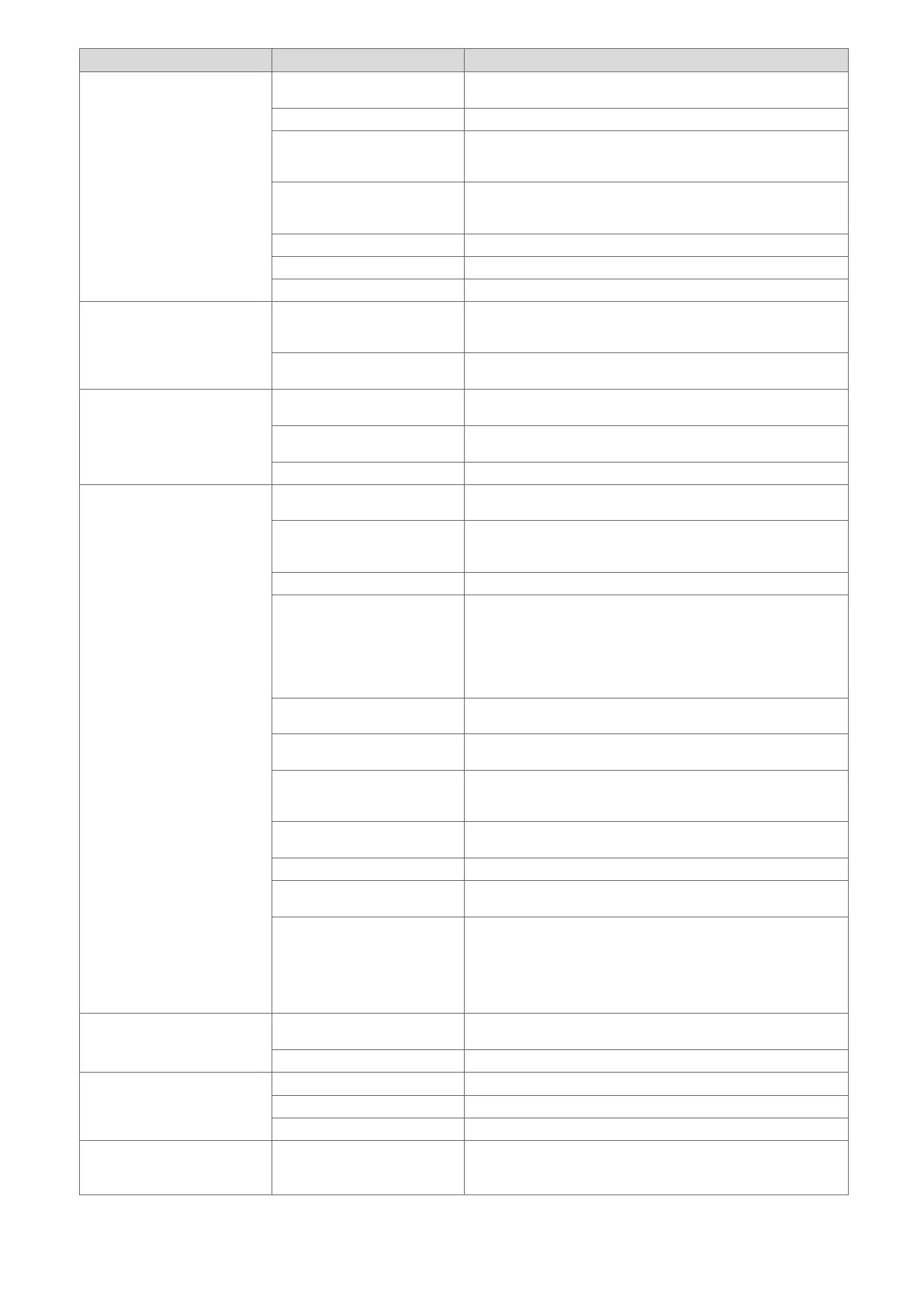

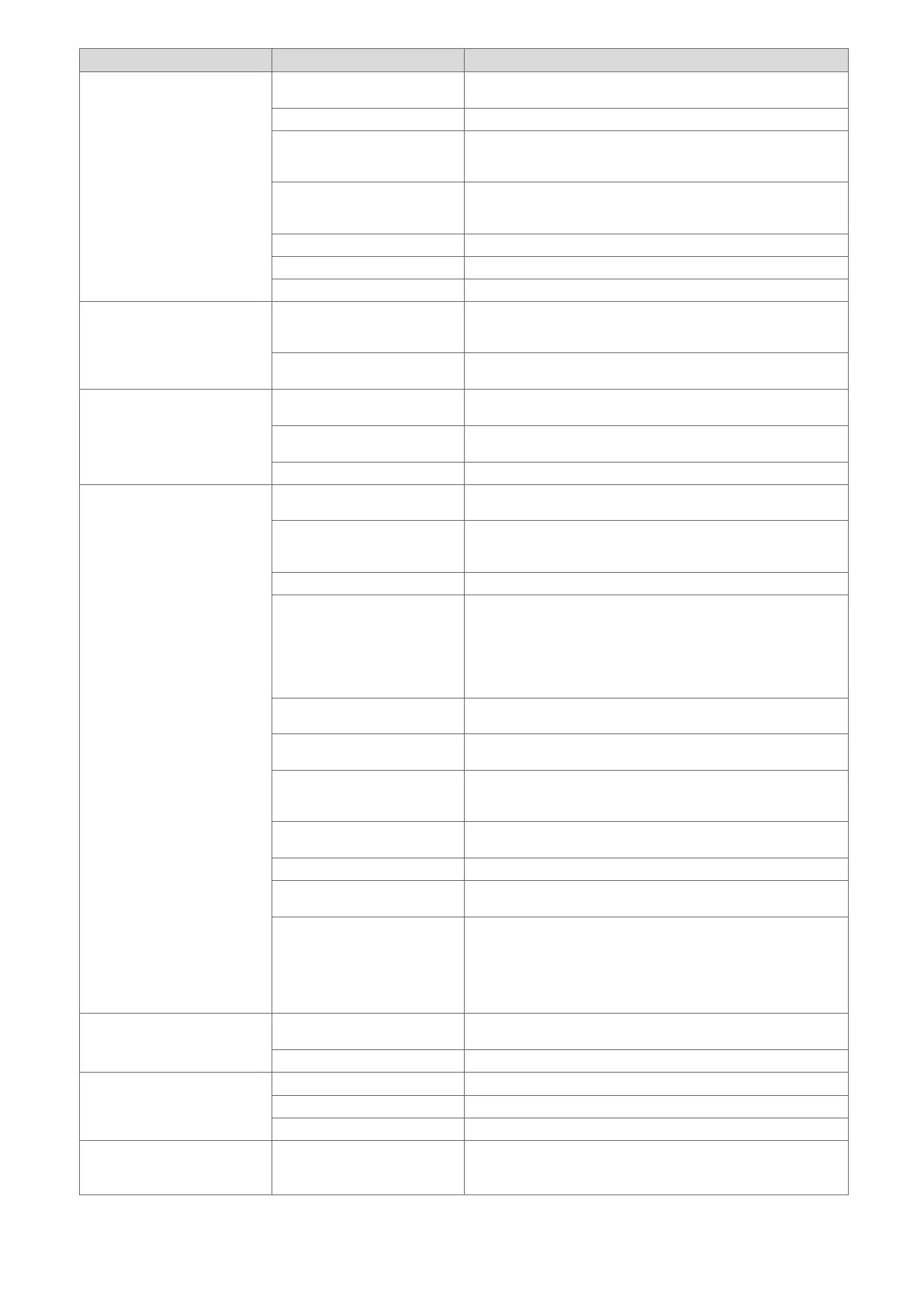

Code/meaning Possible cause Measure

F.044

The ionisation signal for the

control electrode is too low. The

drift adaptation has failed.

Interruption in the wiring har-

ness

▶ Check the wiring harness including all plug connections and, if

required, replace it.

Burner defective ▶ Check and, if required, replace the burner.

Gas valve assembly defect-

ive/incorrect spare part gas

valve assembly

▶ Check and, if required, replace the gas valve assembly.

Gas valve assembly offset in-

correctly stored in D.052 und

ggf. D.182

▶ Check the offset setting for the gas valve assembly.

Control electrode defective ▶

Check and, if required, replace the control electrode.

Gas valve defective ▶ Replace the gas valve.

PCB defective ▶ Replace the PCB.

F.047

The signal for the domestic hot

water temperature sensor at the

output for the internal cylinder is

implausible.

Fault in the electronic connec-

tion for the cylinder outlet tem-

perature sensor

▶ Check the wiring harness between the PCB and sensor, in-

cluding all plug connections.

Cylinder outlet temperature

sensor defective

▶ Replace the cylinder outlet temperature sensor.

F.049

The eBUS has short-circuited or

two active eBUS sources have

inverted polarity.

Short circuit in the eBUS con-

nection

▶ Check all eBUS connections.

Different polarities at the eBUS

connection

▶ Check the polarity (±) of the eBUS connections.

PCB defective ▶ Replace the PCB.

F.057

The combustion regulation has

failed and the associated limp

home mode has failed.

Limp home mode failed ▶ Check the limp home mode and fault history, and carry out the

required measures.

Fault in the flue gas route

caused by recirculation or flue

gas blockage

▶ Check the entire flue gas route.

Air intake pipe blocked ▶ Check and, if required, replace the air intake pipe.

Condensate in the combustion

chamber due to a blocked con-

densate discharge

1. Check and, if required, clean the condensate discharge pipe

including the siphon.

2. Check the combustion chamber (electrodes, insulating mats,

burner).

3. If required, replace the insulating mats in the combustion

chamber.

Condensate pump (if fitted)

defective

▶ Check and clean the condensate pump. Replace the condens-

ate pump, if required.

Gas flow pressure too low ▶ Check the gas flow pressure and the external gas pressure

switch.

Gas valve assembly offset in-

correctly stored in D.052 und

ggf. D.182

▶ Check the offset setting for the gas valve assembly.

Interruption in the wiring har-

ness

▶ Check the wiring harness including all plug connections and, if

required, replace it.

PCB defective ▶ Replace the PCB.

Fan defective ▶ Use D.033 and D.034 to check whether the fan speed deviates

by more than 20–30 rpm.

Air-mass flow sensor dirty or

defective (only in conjunction

with the conversion set compris-

ing the air intake pipe with in-

tegrated non-return valve and

air-mass flow sensor)

1. Check the air-mass flow sensor for dirt.

2. If required, replace the entire air intake pipe.

F.061

The ASIC or µControl does not

run in the defined times.

Fault in the electrical connection

for the gas valve assembly

▶ Check and, if required, replace the wiring harness for the gas

valve assembly.

PCB defective ▶ Replace the PCB.

F.062

The flame switch-off was detec-

ted after a delay.

Gas valve defective ▶ Replace the gas valve.

PCB defective ▶ Replace the PCB.

Ignition electrode defective ▶ Check and, if required, replace the ignition electrode.

F.063

EEPROM reports faults during

the read/write test.

PCB defective ▶ Replace the PCB.

Loading...

Loading...