0020308121_04 Installation and maintenance instructions 87

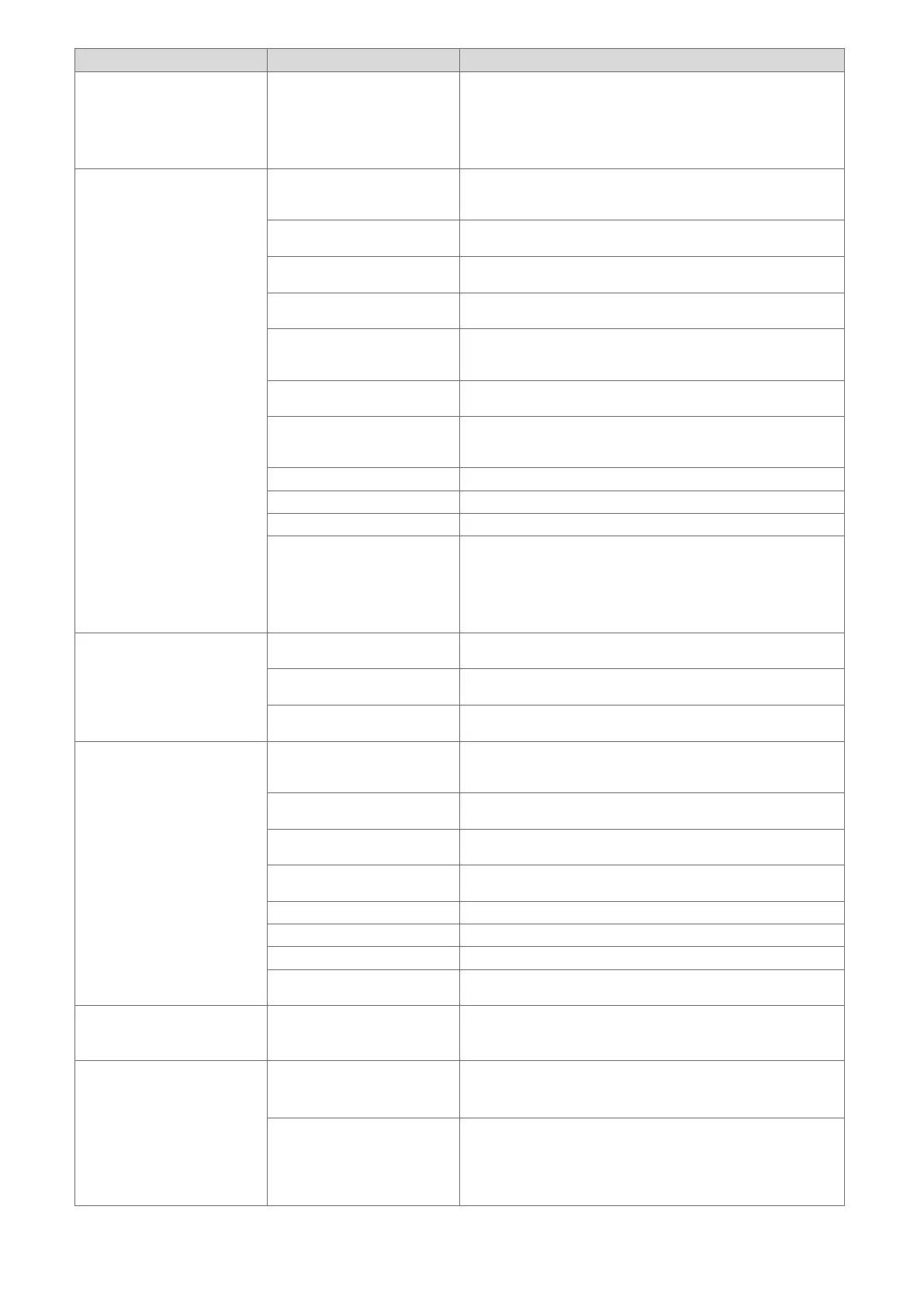

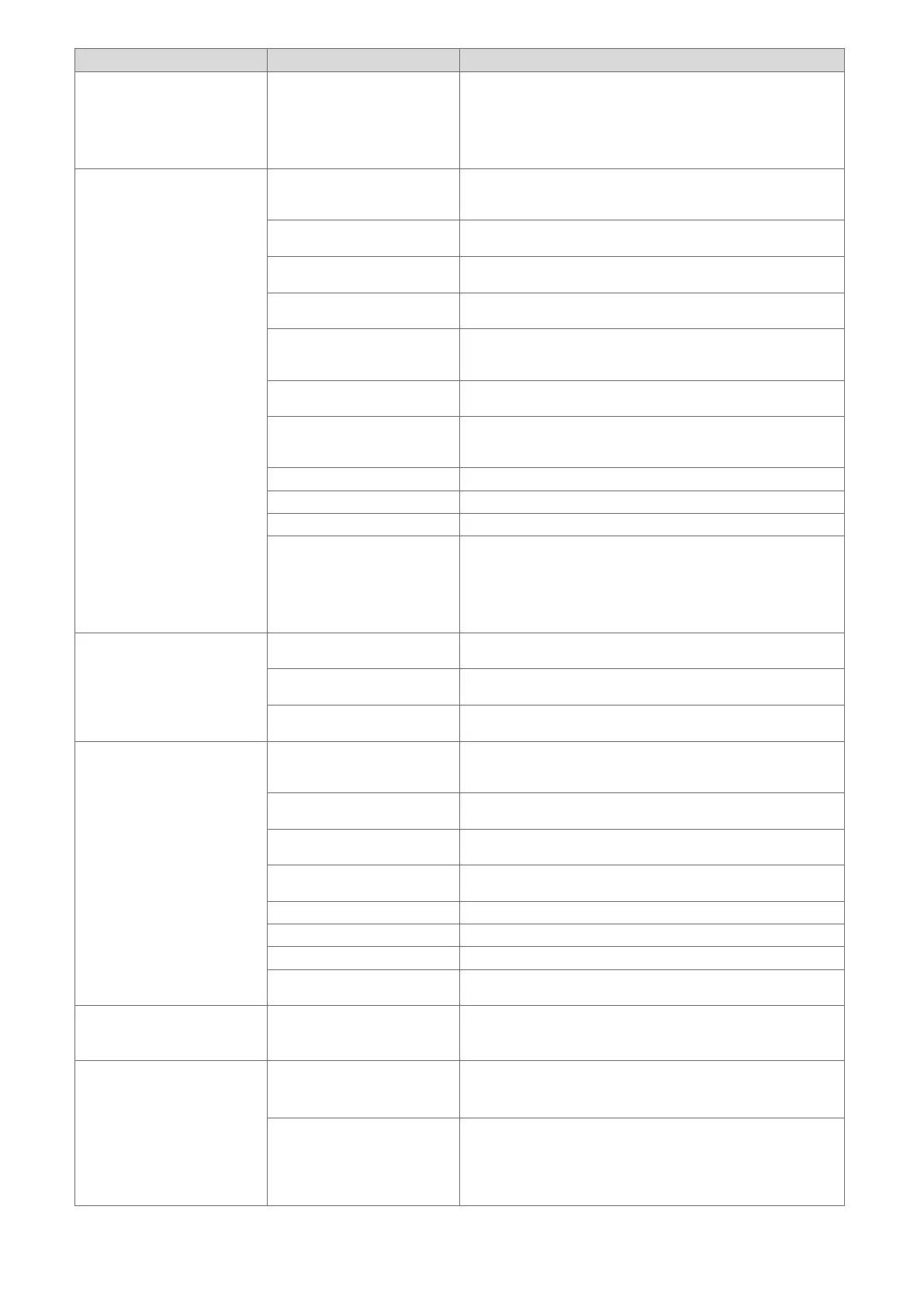

Code/meaning Possible cause Measure

N.096

The gas valve stepper motor

has reached the maximum per-

missible step number.

Air-mass flow sensor dirty or

defective (only in conjunction

with the conversion set compris-

ing the air intake pipe with in-

tegrated non-return valve and

air-mass flow sensor)

1. Check the air-mass flow sensor for dirt.

2. If required, replace the entire air intake pipe.

N.097

The air ratio is too low.

Fault in the flue gas route

caused by recirculation or flue

gas blockage

▶ Check the entire flue gas route.

Condensate discharge pipe

blocked

▶ Check the condensate discharge pipe.

Gas flow pressure too low ▶ Check the gas flow pressure and the external gas pressure

switch.

Incorrect gas type set ▶ Check the gas type and the gas type setting under D.156 and

D.157.

Gas valve assembly offset in-

correctly stored in D.052 und

ggf. D.182

▶ Check the offset setting for the gas valve assembly.

Fault in the electrical connection

for the gas valve assembly

▶ Check and, if required, replace the wiring harness for the gas

valve assembly.

Gas valve assembly not elec-

trically connected/incorrectly

connected

▶ Check the electrical connection to the gas valve assembly.

Control electrode defective ▶ Check and, if required, replace the control electrode.

PCB defective ▶ Replace the PCB.

Fan defective ▶

Check and, if required, replace the fan.

Air-mass flow sensor dirty or

defective (only in conjunction

with the conversion set compris-

ing the air intake pipe with in-

tegrated non-return valve and

air-mass flow sensor)

1. Check the air-mass flow sensor for dirt.

2. If required, replace the entire air intake pipe.

N.100

The signal for the outdoor tem-

perature sensor has been inter-

rupted.

Outdoor temperature sensor not

connected

▶ Check the settings on the control.

Outdoor temperature sensor

defective

▶ Check the outdoor temperature sensor.

Outdoor temperature sensor not

installed

▶ Deactivate the weather-compensated control using D.162.

N.144

The ionisation signal for the

control electrode is too low. The

drift adaptation has failed again.

Fault in the flue gas route

caused by recirculation or flue

gas blockage

▶ Check the entire flue gas route.

Condensate discharge pipe

blocked

▶ Check the condensate discharge pipe.

Gas flow pressure too low ▶ Check the gas flow pressure and the external gas pressure

switch.

Incorrect gas type set ▶ Check the gas type and the gas type setting under D.156 and

D.157.

Control electrode defective ▶ Check and, if required, replace the control electrode.

Gas valve defective ▶ Replace the gas valve.

PCB defective ▶ Replace the PCB.

Interruption in the wiring har-

ness

▶ Check the wiring harness including all plug connections and, if

required, replace it.

N.194

The power supply unit for the

PCB is defective.

Power supply unit for the PCB

is defective

▶ Replace the PCB.

N.270

The temperature spread via

the secondary heat exchanger

(heating flow – domestic hot

water connection) is too high.

The unit switches from regulat-

ing to controlling until the cause

has been eliminated by cus-

tomer service.

Strainer at cold water inlet dirty ▶ Check the strainer at the cold water inlet for dirt, clean it and, if

required, replace it.

Cold water adjusting valve not

installed (only on a product with

no factory-installed flow rate

limiter)

▶ Install the cold water adjusting valve.

Loading...

Loading...