VAMP 220 / 220R Arc protection system

User manual

VAMP Ltd

36

Vamp 24h support phone : +358 (0)40 573 6316

VM220.EN004

X2

X3

X1

X6

X2

X3

X1

X6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

8

9

10

11

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

8

9

10

11

14

15

16

17

18

La> BIO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

8

9

10

11

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

8

9

10

11

14

15

16

17

18

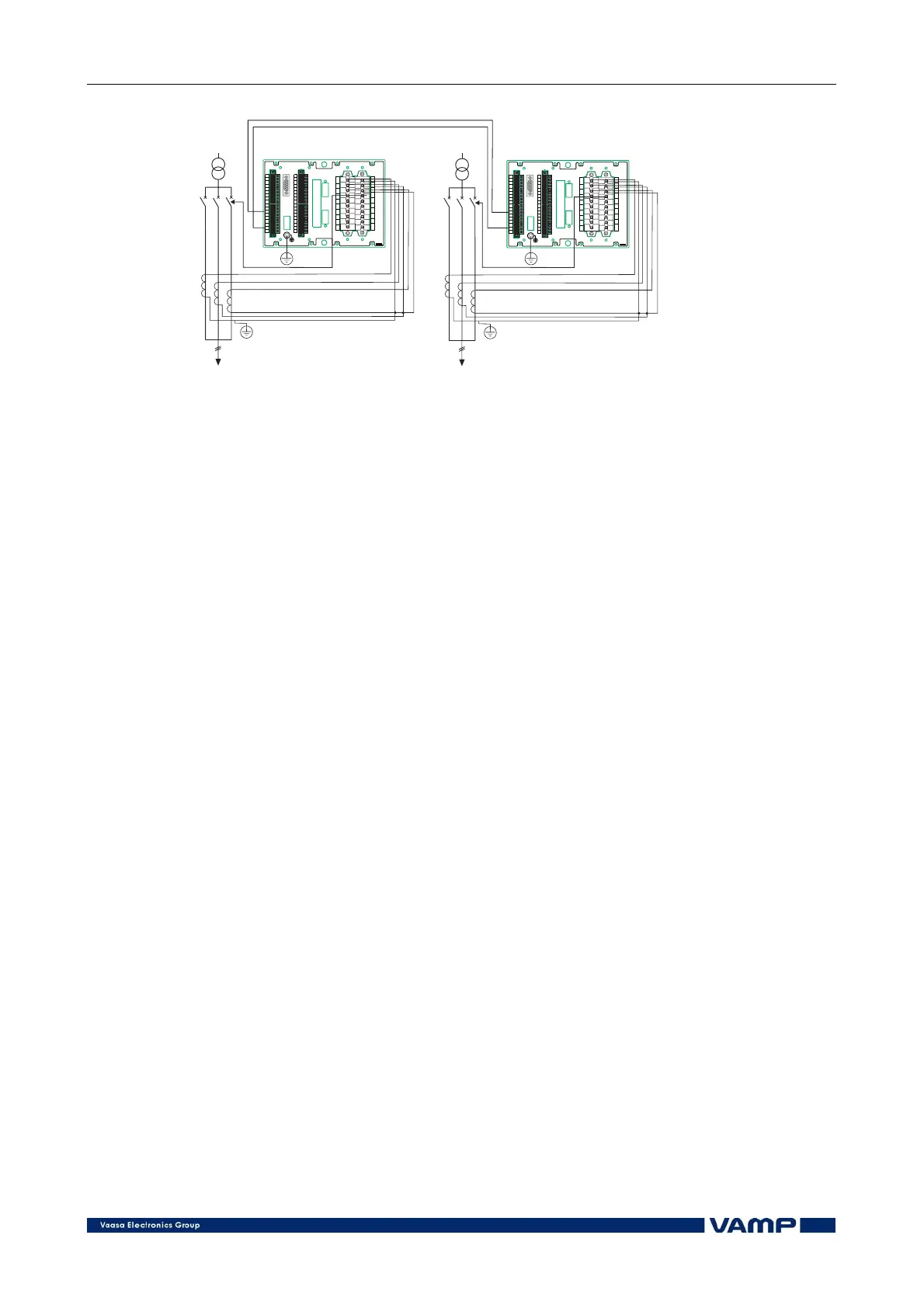

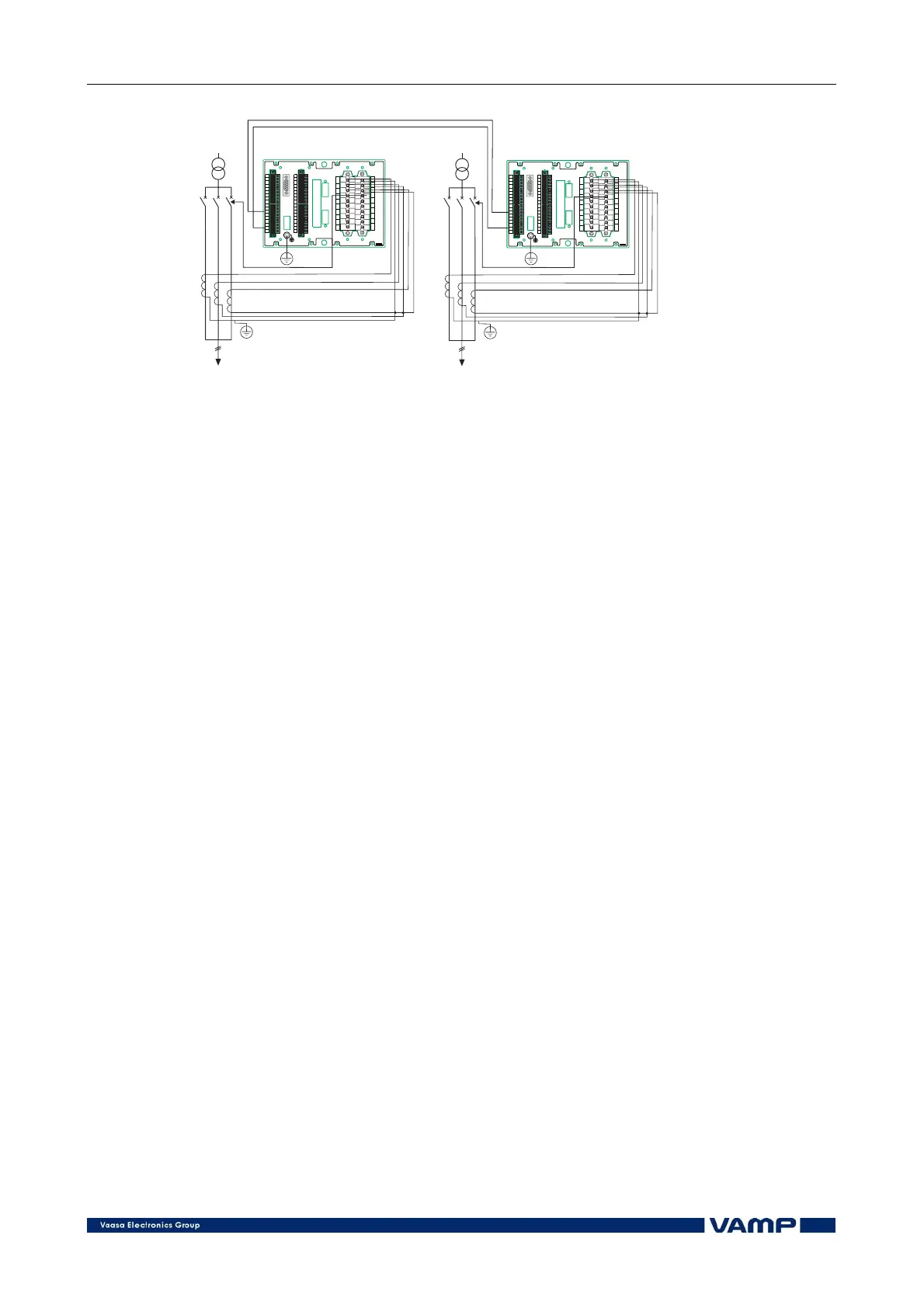

Figure 5.7-1 Arc protection system with two master units (example).

5.8. Wiring systems with selective arc

protection

Wire the system as follows:

• Connect the arc sensors of one certain zone in normal way

to the slave units.

• Connect each slave unit to a master unit belonging to the

zone.

• Connect the bidirectional arc information La via the BI/O

bus (terminal X3-12,17) to all master units in that zone.

The unidirectional arc information (terminals X3-14,17, Lc>)

can be fed from the master unit (terminals X3-12,17, La>) of

the next zone. By doing so, the system will trip also the circuit

breakers which feed the next zone. See Figure 2.7-1.

5.9. Checking wirings

Check the secondary wiring by visual inspection and, when

needed, by measuring, to eliminate possible incorrect wirings,

which may cause malfunction of the system or associated

devices.

5.9.1. Visual inspection

Perform a visual inspection of the wiring. Especially check the

wire bunches for adequate slack where needed over hinges.

Check the screw terminals for correct tightness.

Check, that no wire strands are protruding from the terminals.

Loading...

Loading...