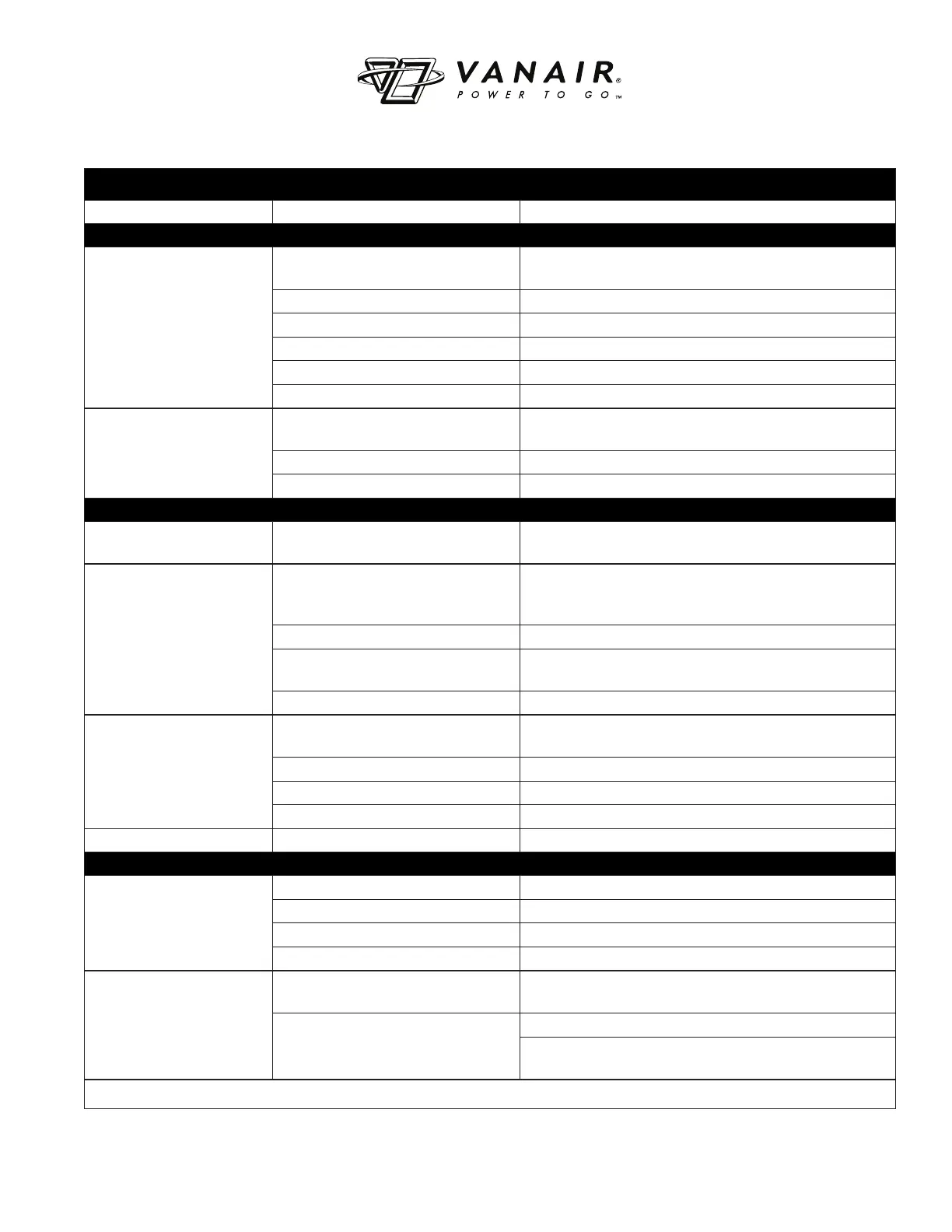

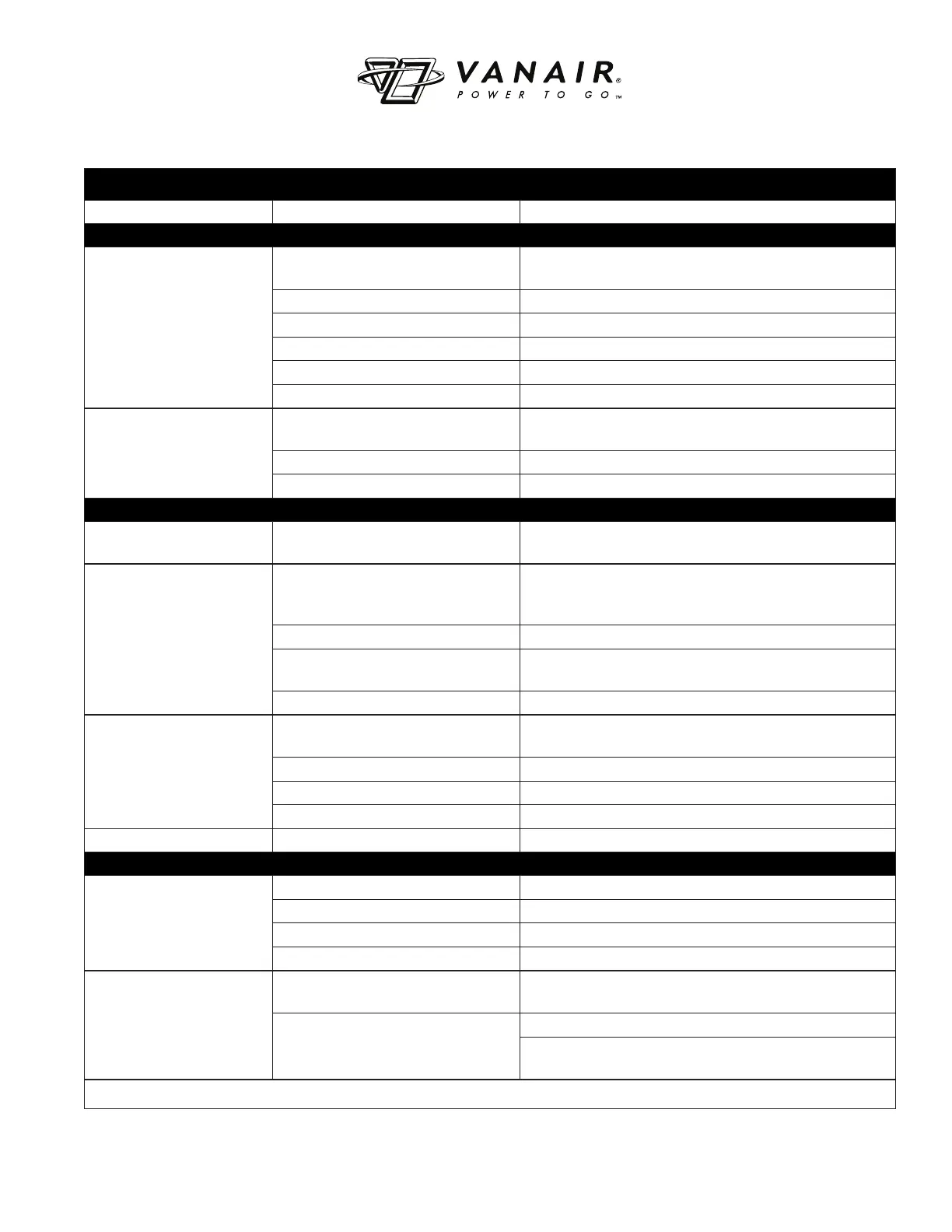

SECTION 6: TROUBLESHOOTING

090189-OP_r0 (JUNE-2022) 6 - 3

VANAIR MANUFACTURING, INC.

(844) VAN-SERV • www.vanair.com

Cap•Start Hydraulic-Driven

12V/24V • Battery Starter • Charger

6.2 TROUBLESHOOTING GUIDE - HYDRAULICS

MALFUNCTION/FAULT POSSIBLE CAUSE CORRECTIVE ACTION

HYDRAULIC DRIVE SYSTEM: INCORRECT FLOW CONDITION (CONTINUED)

Flow is low Flow control is set too low (Closed Cen-

ter System [CCS])

Adjust as necessary.

Relief valve is set too low Adjust as necessary.

Partial fl ow passing over relief Adjust as necessary.

External leak in the system exists Locate and tighten leaking connections.

Pump drive motor RPM is incorrect Replace with correct unit.

Pump, valve, motor is/are worn Overhaul or replace item as noted.

Flow is excessive Flow control is set too high (Closed

Center System [CCS])

Adjust as necessary.

Pump drive motor RPM is incorrect Replace with correct unit. Adjust vehicle RPM.

Replacement pump is not properly sized Replace with correct unit.

HYDRAULIC DRIVE SYSTEM: INCORRECT PRESSURE CONDITION

Pressure is absent No fl ow Refer to information in the “No Existing Flow” column under

INCORRECT FLOW CONDITION in this guide

Pressure is low Pressure relief path is present Refer to information in the “No Existing Flow” and the “Flow is

Low” columns under INCORRECT FLOW CONDITION in this

guide

Pressure relief valve is set too low Adjust pressure relief valve. Rebuild or replace if necessary.

Pressure relief valve is damaged or

inoperable

Rebuild or replace pressure valve.

Pump or motor is damaged or inoperable Overhaul or replace as necessary.

Pressure is erratic Air is present in fl uid Tighten leaking connections, fi ll reservoir to proper level, and

bleed air from system.

Relief valve is worn or inoperable Rebuild or replace valve.

Fluid is contaminated Check system fl uid and fi lters; replace if necessary.

Pump or motor is worn Overhaul or replace as necessary.

Pressure is excessive Pressure relief valve out of adjustment Adjust; Rebuild or replace if necessary.

HYDRAULIC DRIVE SYSTEM: FAULTY OPERATION

Hydraulic Flow Is Present But

Motor Does Not Rotate

Mechanically bound Locate the bind, and repair.

Command signal solenoid is absent Contact the Vanair

®

Service Department.

Solenoid valve is inoperative Replace valve.

Motor is worn or damaged Overhaul or replace motor.

Hydraulic Flow Is Present But

Motor Rotates Slowly

Low system fl ow Refer to information under INCORRECT FLOW CONDITION in

this guide.

Viscosity of fl uid too high Fluid may be too cold; allow system to warm up.

Fluid may be fouled; change system fl uid to correct viscosity

fl uid.

Table continued on next page

Loading...

Loading...