SECTION 6: TROUBLESHOOTING

6 - 2 090189-OP_r0 (JUNE-2022)

VANAIR MANUFACTURING, INC.

(844) VAN-SERV • www.vanair.com

Cap•Start Hydraulic-Driven

12V/24V • Battery Starter • Charger

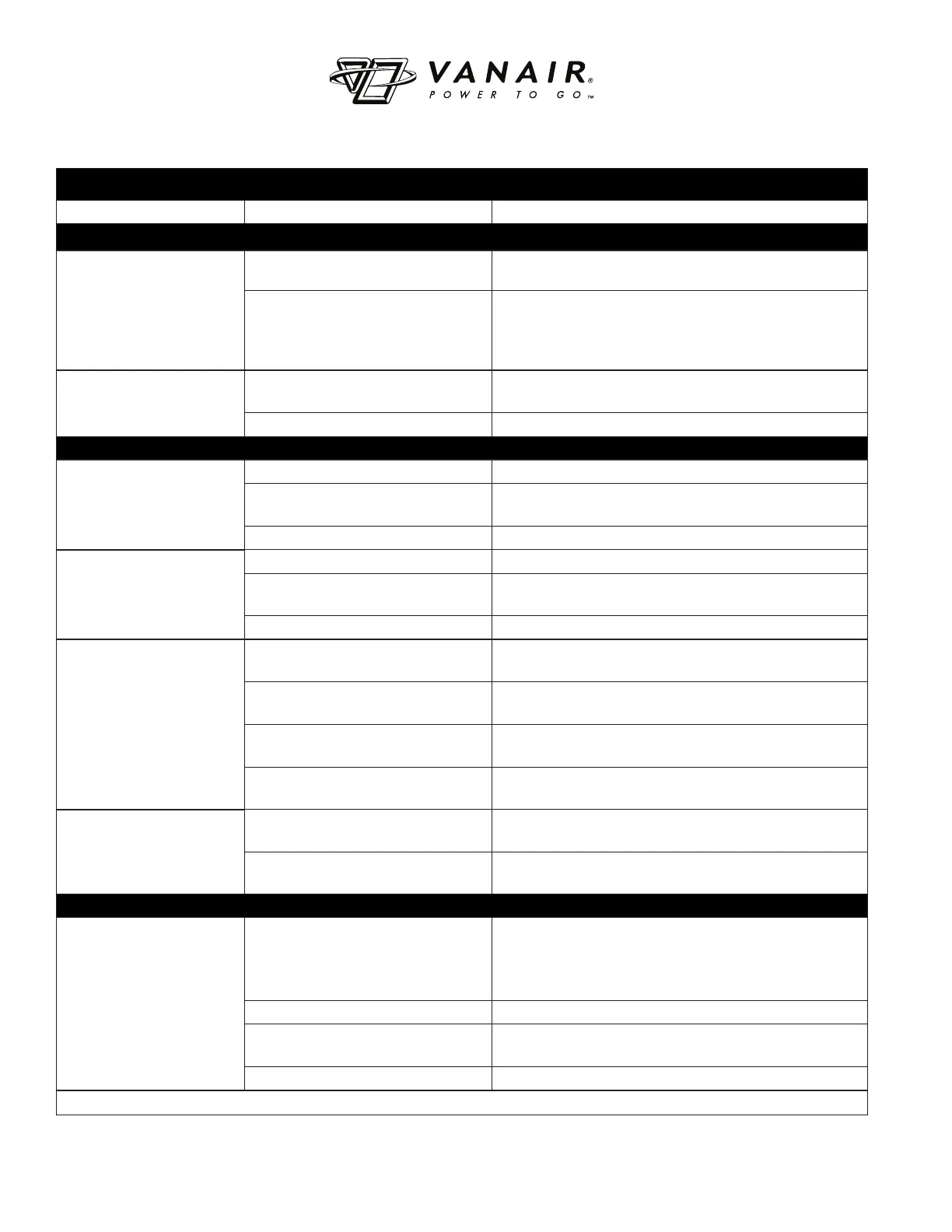

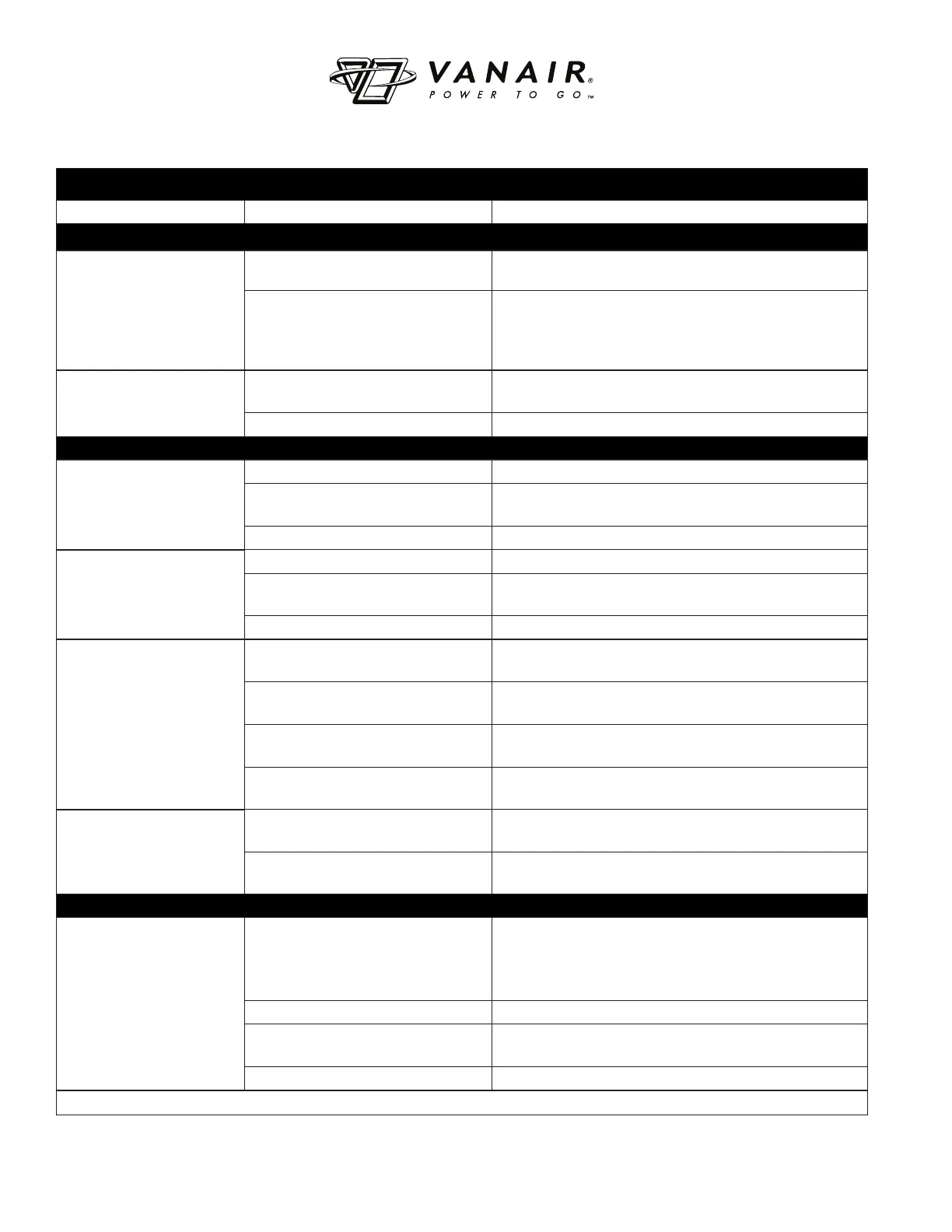

6.2 TROUBLESHOOTING GUIDE - HYDRAULICS

MALFUNCTION/FAULT POSSIBLE CAUSE CORRECTIVE ACTION

HYDRAULIC DRIVE SYSTEM: EXCESSIVE NOISE

Motor is too noisy Coupling is mis-aligned Align unit and check condition of seals, bearings and coupling.

Motor and/or coupling is/are worn or

damaged

Regard any or all of the following: Tighten leaking connections;

fi ll reservoir to proper level (with rare exception all return lines

should be below fl uid level in reservoir); bleed air from system;

replace pump shaft seal (and shaft if worn at seal journal).

Relief valve too noisy Valve setting is set too low or too close to

another valve setting

Install pressure gauge and adjust to correct pressure.

Worn poppet and/or seat Overhaul or replace poppet and/or seat.

HYDRAULIC DRIVE SYSTEM: EXCESSIVE HEAT

Motor is heated Fluid is heated Refer to information under “Fluid is heated” heading below.

Relief or unloading valve is set too high Install pressure gauge and adjust to correct pressure (keep at

least 125 psi difference between valve settings).

Motor is worn or damaged Overhaul or replace motor.

Relief valve is heated Fluid is heated Refer to information under “Fluid is heated” heading below.

Valve is set incorrectly Install pressure gauge and adjust to correct pressure (keep at

least 125 psi difference between valve settings).

Valve is worn or damaged Rebuild or replace valve.

Fluid is heated System pressure is too high Install pressure gauge and adjust to correct pressure (keep at

least 125 psi difference between valve settings).

System pressure is too high Install pressure gauge and adjust to correct pressure (keep at

least 125 psi difference between valve settings).

Fluid is fouled or quantity too low Change fi lters and also system fl uid if improper viscosity; fi ll

reservoir to proper level.

Fluid viscosity is not correct Change fi lters and also system fl uid if improper viscosity; fi ll

reservoir to proper level.

Oil discharge from regulator

weep hole

Fluid cooling system is faulty Clean cooler and/or cooler strainer; replace cooler control valve;

repair or replace cooler.

Pump, valve, motor, cylinder or other

component is/are worn

Overhaul or replace item as noted.

HYDRAULIC DRIVE SYSTEM: INCORRECT FLOW CONDITION

No existing fl ow at motor Motor not receiving fl uid Regard any or all of the following:

Replace dirty fi lters; clean clogged inlet line; clean or replace

reservoir breather vent; fi ll reservoir to proper level; overhaul or

replace supercharge pump.

Entire fl ow passing over relief valve Adjust as necessary.

Pump is damaged Check for damaged pump or pump drive—replace as neces-

sary, and align coupling.

Pump is assembled improperly Overhaul or replace pump.

Table continued on next page

Loading...

Loading...