SECTION 3: INSTALLATION

3 - 2

090189-OP_r0 (JUNE-2022)

VANAIR MANUFACTURING, INC.

(844) VAN-SERV • www.vanair.com

Cap•Start Hydraulic-Driven

12V/24V • Battery Starter • Charger

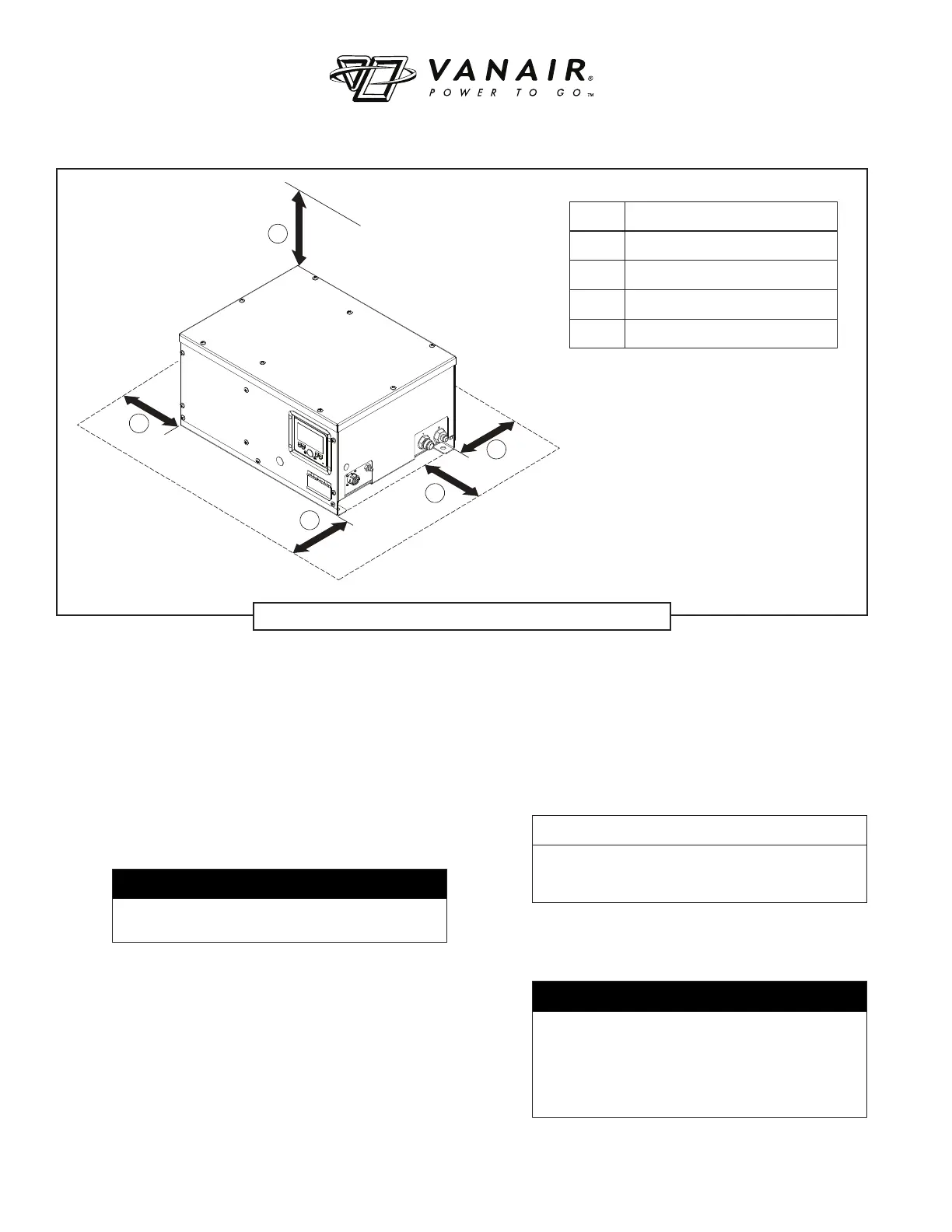

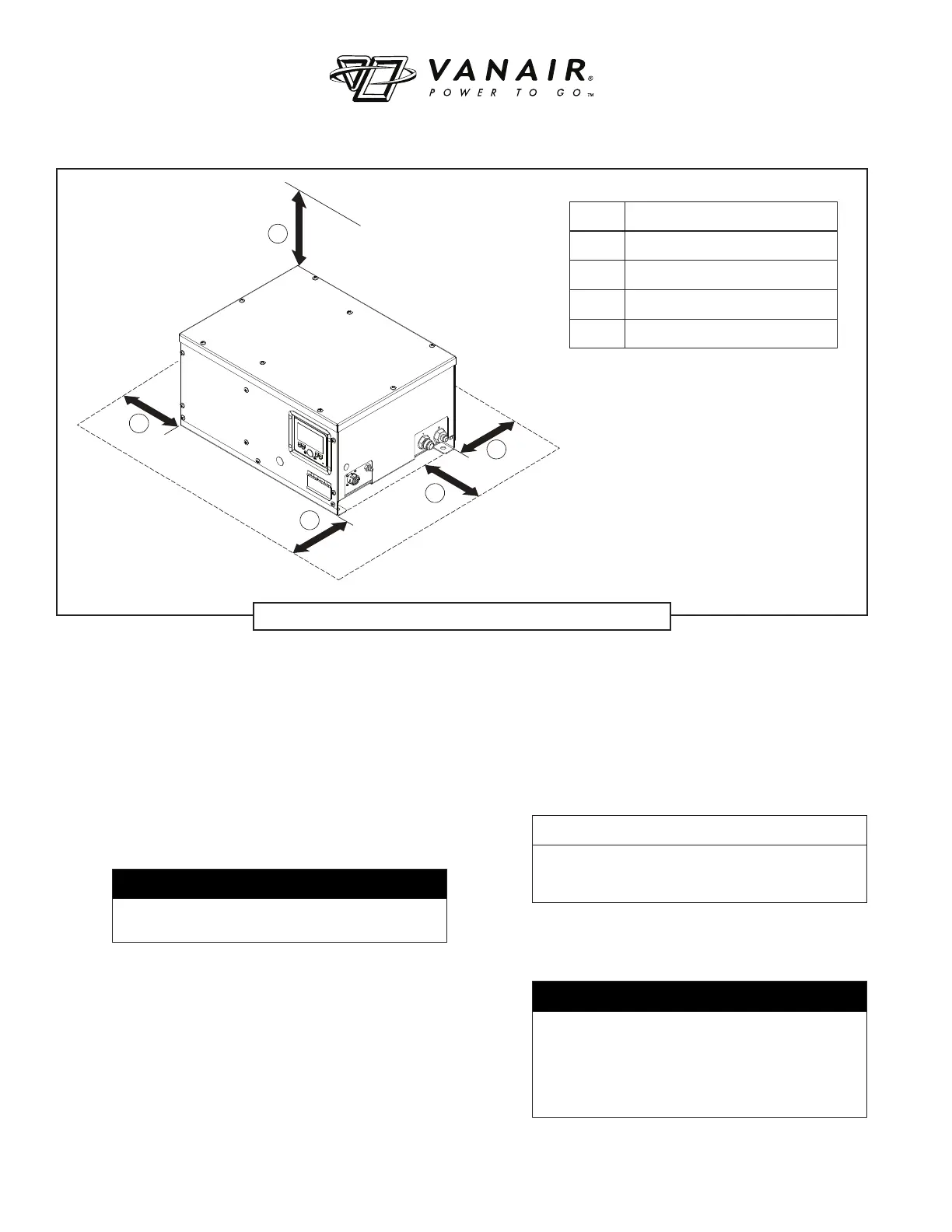

3.3 DETERMINING THE MACHINE

MOUNTING LOCATION

When determining the location to mount the

Cap•Start Hydraulic unit, the following criteria

must be taken into consideration:

• The mounting surface must be level and able to

accommodate the four (4) mounting bolts and

isolators of the base frame. Refer to Figure

3-1 or Figure 3-2 for clearance room and lay-

out of mounting hole slots’ locations.

IMPORTANT

Mounting surface must be able to bear the

weight of the machine (245 lbs).

• Mount the machine with a minimum of four (4)

mounting locations.

• The location must allow for the machine dimen-

sions, and additional space requirements for

minimum cooling, maintenance and access.

Refer to Figure 3-3 to determine the additional

minimum space requirement measurements.

• The external gauges/display must be easily vis-

ible to the operator.

It is recommended, for most installations, to

mount the

machine on the driver’s side of the ve-

hicle. The unit should be situated in such a man-

ner that the fan (rear) and hydraulic cooler (front)

are not obstructed. Do not place the

machine in

any location where it can ingest exhaust fumes,

dust or debris.

NOTE

When considering external system layout hoses

refer to Section

7.12, Hose Guide for proper

routing and mounting practices.

3.4 HYDRAULIC SYSTEM

OVERVIEW

IMPORTANT

Vanair

®

highly recommends consulting a hy-

draulic supply expert for specifying the correct

hydraulic supply components for vehicle-side

integration (including oil reservoir size, hy-

draulic pressure relief, hose size, etc.) for your

application.

A

B

B

C

C

Figure 3-1: Machine Minimum Operational Clearance

KEY DESCRIPTION

A MINIMUM CLEARANCE: 8"

B MINIMUM CLEARANCE: 8"

C MINIMUM CLEARANCE: 8"

D MINIMUM CLEARANCE: 8"

Loading...

Loading...