EMR3 Truck Installation Installation Procedures - Fuel Oil Truck Application

11

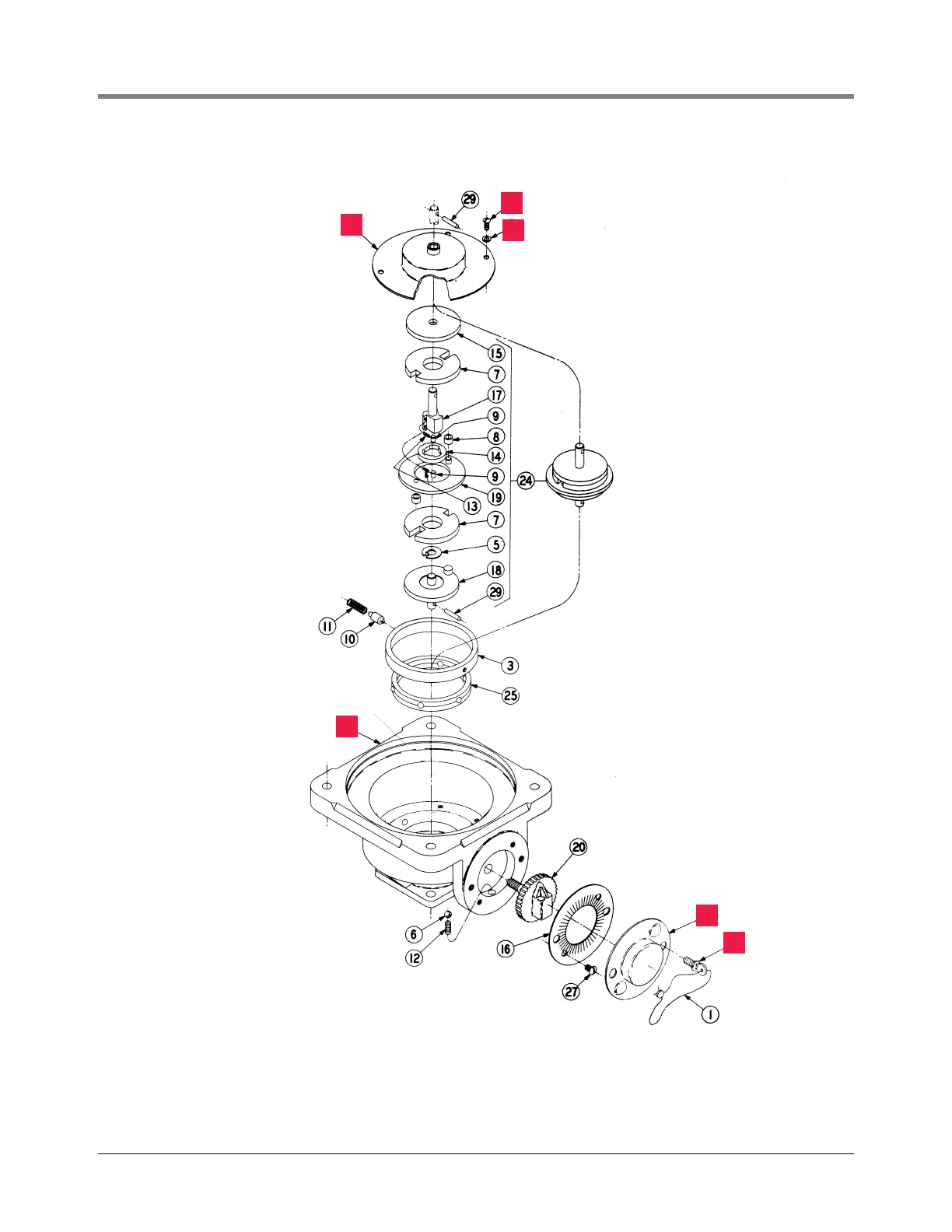

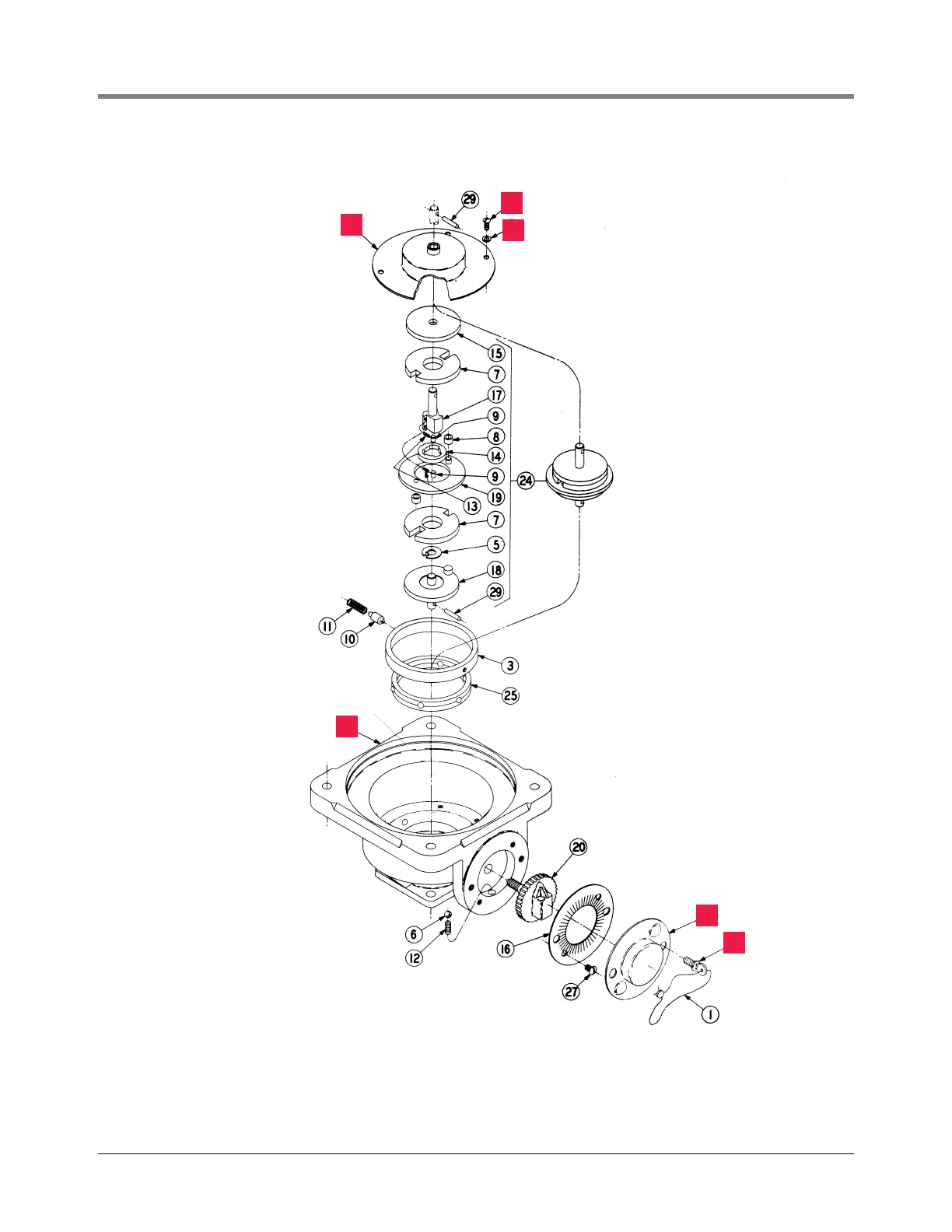

Figure 7. Disassembling the Tokheim Daniels, & Donovan calibrator

22

23

4

28

26

21

Disassemble the Tokheim

calibrator and keep parts

4, 21, 22, 23, 26, and 28

(items in square blocks)

emr\tok1.eps

Loading...

Loading...