SERVICE

Service - 49

engine speed for a few minutes. Turn the steer-

ing wheel to the left and right a couple of times to

purge any trapped air out of the hydraulic system.

13. Shut o the power unit engine and allow the

power unit to sit for a minimum of ve minutes.

14. Check the hydraulic oil level. Refer to the Checking

the Hydraulic Oil Level section.

15. Inspect both of the hydraulic lters for signs of

leakage. If any leaks are evident, the lter may

need tightened further, or the lter may need to

be removed, the gasket and lter mount cleaned,

and the lter reinstalled following the procedures

for changing the lter.

16. Reinstall the hydraulic lter access cover.

Changing the Hydraulic Oil

1. Wash the underside of both the front and rear

transaxles thoroughly.

2. Park the power unit on a level surface and adjust

the steering to aim the power unit straight ahead.

3. Fully raise the front hitch and lower the 3 point

hitch (if equipped).

4. Shut o the engine and allow time for the hydrau-

lic system to cool.

WARNING

Hot oil can cause severe burns. Allow the oil tem-

perature to drop from hot to warm before draining

the hydraulic oil.

5. Place a drain pan (minimum 13.5 liter / 14 quart)

under the front transaxle.

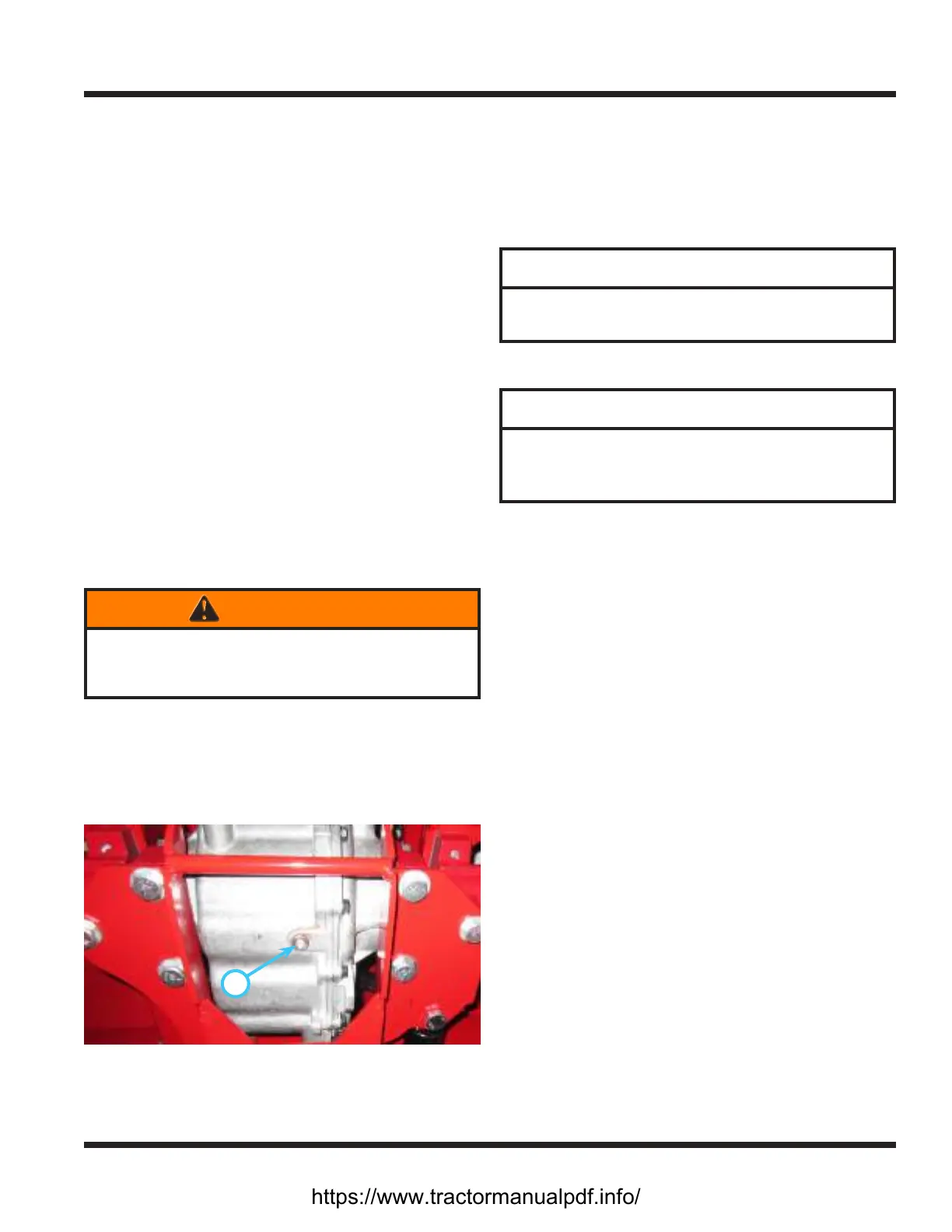

6. Remove the drain plug (A) from the front trans-

axle and allow the hydraulic oil to drain from the

system. Loosen the cap on the hydraulic oil tank

to allow venting.

7.

A

If the transaxle is equipped with a pipe plug,

clean the drain plug and apply pipe sealant to the

threads, making sure to leave the last two threads

bare to prevent the thread sealant from contami-

nating the hydraulic oil. Reinstall the plug into the

front transaxle and tighten 1 to 1-1/2 turns past

nger tight (approximately 48-54 Nm / 35-40 ft-lbs

of torque).

If the transaxle is equipped with an o-ring plug,

reinstall the plug into the rear transaxle and

torque to 34-39 Nm (25-29 ft-lbs).

ATTENTION

Do not overtighten the transaxle plug. Overtighten-

ing can cause the transaxle case to crack.

8. Clean up any spilled oil and dispose of oil in accor-

dance with local laws.

ATTENTION

Oil is hazardous to the environment. Drain oil into

an approved container and dispose of used oil in

accordance with local laws.

9. If the hydraulic lters are being changed with the

oil, proceed to the Changing the Hydraulic Oil

Filters section before completing the remaining

steps in this section.

10. Add HydroTorq XL synthetic hydraulic oil to the

hydraulic oil tank until the oil level in the plastic

sight tube is within the proper range indicated by

the oil level decal.

11. Start the power unit and let it run at low idle

engine speed for a few minutes. Turn the steer-

ing wheel to the left and right a couple of times to

purge any trapped air out of the hydraulic system.

12. Shut o the power unit engine and allow the

power unit to sit for a minimum of ve minutes.

13. Check the hydraulic oil level. Refer to the Checking

the Hydraulic Oil Level section.

https://www.tractormanualpdf.info/

Loading...

Loading...