- Check the continuity of the cable harness between the sensor connector and control unit connector:

Control unit PIN 13 - sensor PIN 1 and control unit PIN 15 - sensor PIN 2. Restore the cabling if nec-

essary.

- If the cabling is intact but the sensor resistance value is incorrect, this means that the sensor is faulty

and must be replaced, otherwise proceed with the checks.

Shorted to positive:

- With the sensor connector and the control unit disconnected, verify that the fault is shorted with the

battery positive of sensor connector PIN 1 (or control unit PIN 13) and restore the cabling.

Shorted to negative:

- Disconnect the sensor connector.

- Check the sensor connector PIN 1 ground insulation.

- If there is no ground insulation restore the cabling.

- If PIN 1 is insulated from the ground and the error persists, this means that there is a probable fault

in the control unit.

LAMBDA PROBE

Function

In charge of telling the control unit whether the

mixture is lean or rich.

Operation / Operating principle

Based on the difference of oxygen in the exhaust

fumes and the environment, this generates volt-

age which is read and interpreted by the injection

control unit. It does not require an external supply

source but, in order to work properly, it should

reach a high operating temperature: that is why

there is a heating circuit inside.

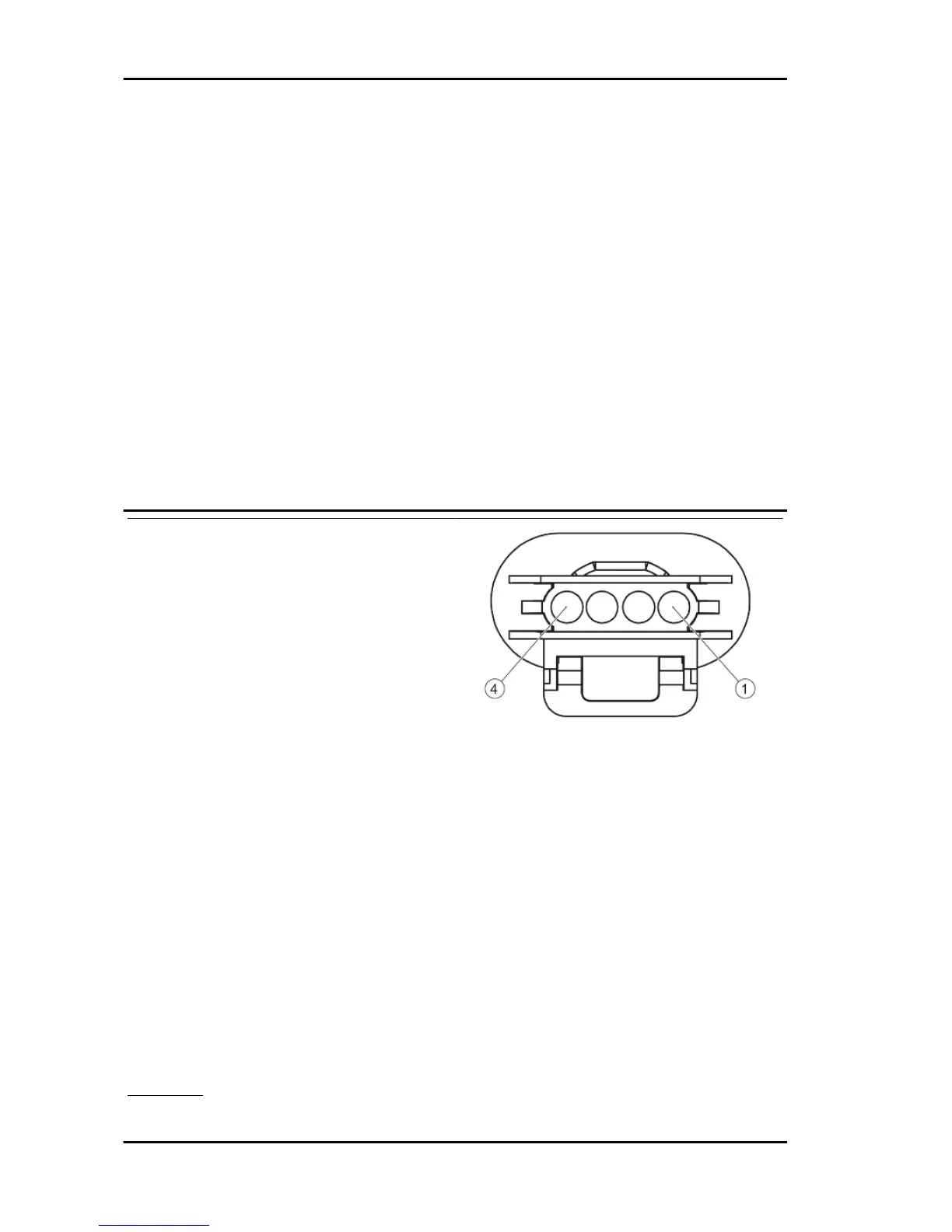

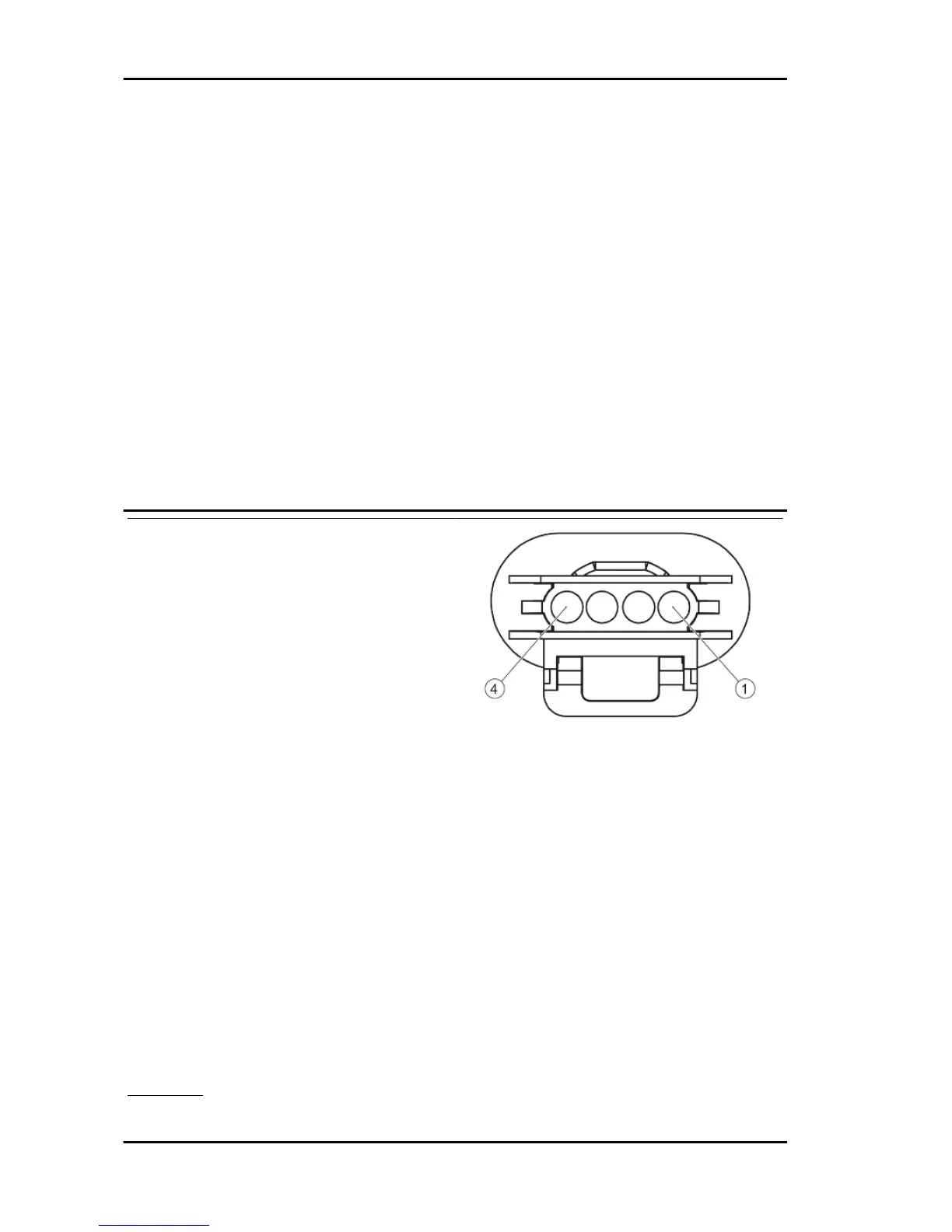

Pinout:

1. Heater supply (1)

2. Heater ground (2)

3. Sensor signal + (3)

4. Sensor signal - (4)

ELECTRICAL ERRORS

Check the air-fuel ratio / Lambda probe P0130 - short circuit to positive / open circuit, short circuit to

negative or carburetion excessively lean / signal not plausible for abnormal title correction or probe

signal fault.

Error cause

Shorted to positive: excessive voltage at PIN 11 or PIN 12 of the control unit connector.

Electrical system Vespa LX - S 125 3V ie 150 3V ie (2012)

ELE SYS - 104

Loading...

Loading...