Prevent excessive scale build-up (calcium carbonate) on the heating

surfaces. For heating systems with operating temperatures up to

100 °C, the VDI Directive 2035 sheet 1 "Prevention of heating system

damage in hot water heating systems - scaling in DHW and hot water

heating systems" applies [in Germany; check local regulations] with

the following guide values. For more detailed information, see the

annotations to VDI Directive 2035.

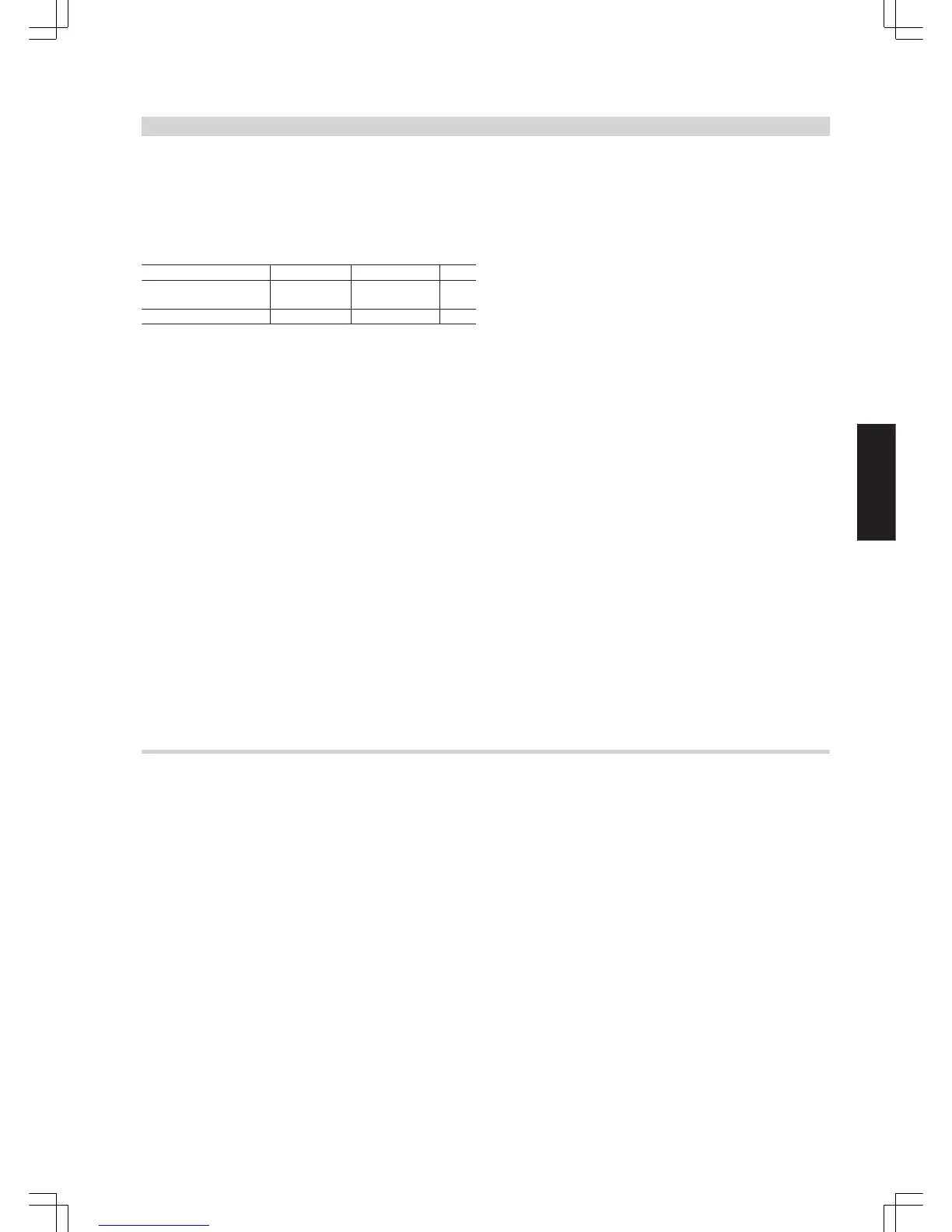

Total output in kW

> 50 to ≤ 200 > 200 to ≤ 600

> 600

Total alkaline

earths in mol/m

3

≤ 2.0 ≤ 1.5

< 0.02

Total hardness in °dH

≤ 11.2 ≤ 8.4

< 0.11

The standard values assume the following:

■ The volume of fill and top-up water of the heating system during its

service life will not exceed three times the water content of the heat-

ing system.

■ The specific system volume is less than 20 l/kW output. In multi-

boiler systems, apply the output of the smallest boiler.

■ All measures to prevent corrosion on the water side in accordance

with VDI 2035 Sheet 2 have been implemented.

Soften the fill & top-up water in heating systems operating under the

following conditions:

■ The total of alkaline earths in the fill & top-up water exceeds the

standard value.

■ Higher fill & top-up water volumes are expected.

■ The specific system volume is higher than 20 l/kW output. In multi-

boiler systems, apply the output of the smallest boiler.

When engineering the system, observe the following:

■ Install shut-off valves in different sections. This prevents the need

for draining the entire heating water in case of repairs or system

expansion.

■ Install a water meter to record the amount of the fill & top-up water.

Enter the volume of water and the water hardness into the boiler

service instructions.

■ For systems with a specific system volume in excess of 20 l/kW out-

put (for multi-boiler systems, apply the output of the smallest boiler),

apply the requirements of the next highest category of total output

(in accordance with the table). In case of severe excess (> 50 l/kW),

soften down to the total of alkaline earths

≤

0.02 mol/m

3

.

Operating information:

■ Bring the system into use step by step, starting with the lowest boiler

output and at a high heating water flow rate. This prevents a localised

concentration of lime deposits on the boiler heating surfaces.

■ In multi-boiler systems, start all boilers simultaneously to prevent the

entire lime deposit settling in the heat transfer area of just one boiler.

■ During expansion or repair work, only drain the necessary sections.

■ Where water treatment is required, treat even the first fill of the heat-

ing systems prior to commissioning. This also applies to any subse-

quent filling, e.g. when adding top-up water or after a repair or after

system expansion.

■ Filters, dirt traps and other blow-down or separating facilities in the

heating water circuit must be checked, cleaned and activated more

frequently after commissioning or recommissioning, and later on as

required, subject to the water treatment applied (e.g. water soften-

ing).

The build-up of lime deposits on the heating surfaces will be minimised

if these instructions are observed.

Any lime deposits that have formed because the requirements to VDI

Guideline 2035 have not been observed will in most cases already

have caused a reduction in the service life of the installed heating

equipment. Removing the lime deposits is one option to restore the

operational viability. This measure must be carried out by the

Viessmann industrial services or a specialist company. Inspect the

heating system for possible damage prior to returning it into use. It is

essential that the faulty operating parameters are corrected to prevent

renewed formation of excessive scale deposits.

Heating systems with permissible flow temperatures in excess of 100 ºC (VdTÜV DS 1466)

Operation with circulating water with low salt content

Only use water with a low salt content as fill or top-up water, such as

desalinated water, permeate or condensate.

Systems using mixed condensate generally create water with low salt

content if no boiler water is fed into the system for putrefaction by

alkalis.

Operation with saline water

Where possible, use water with a low salt content that is at least free

from alkaline earths (softened) as fill or top-up water.

Design information

(cont.)

OIL/GAS BOILERS

VIESMANN

45

5822 426 GB

10

Loading...

Loading...