Gas installation

The gas installation should be carried out by the registered installer in

accordance with the technical connection requirements stipulated by

the gas supply utility. Operate the system in accordance with the above

conditions.

Pipe connections

All pipe connections to the boiler should be made free from stress and

torque.

Electrical installation

Carry out the electrical connection and installation in accordance with

VDE regulations (DIN VDE 0100 and DIN VDE 0116), local regulations

and the technical connection requirements laid down by your electricity

supply company.

■ DIN VDE 0100: Installation of HV systems with rated voltages up to

1000 V.

■ DIN VDE 0116: Electrical equipment for combustion systems.

Operating instructions

According to EN 12828, section 5 and EN 12170/12171, the system

installer must produce operating instructions for the whole system.

Flue system

Only flue pipes that meet Building Regulations or that are CE-desig-

nated may be used with condensing systems.

Energy Saving Ordinance (EnEV)

■

Paragraph 11 (2), oil and gas combustion systems ≤ 400 kW:

Compulsory for low temperature or condensing boilers with CE des-

ignation that, according to the Declaration of Conformity, are identi-

fied as low temperature or condensing boilers (in accordance with

Directive 92/42/EEC), for buildings, whose annual primary energy

demand is not limited in accordance with EnEV paragraph 3 (1).

German Immissions Order (BImSchV)

Combustion systems must be operated so that the limits stated in the

1st BImSchV of 26.01.2010 or the TA Luft – for systems listed in the

4th BImSchV of 11.08.2009 – will not be exceeded. The 1st BImSchV

applies to oil and gas combustion systems for heating buildings or

rooms with water as a heat transfer medium.

■ 1st BImSchV, paragraph 6

Section 3, oil and gas combustion systems

– Oil and gas combustion systems > 400 kW for heating buildings

or rooms:

The manufacturer must certify that the efficiency is

≥

94 % (cal-

culated to EN 303–5, version 6/1999).

– The requirements of section 3 are deemed to have been met for

boilers > 1 MW if the boiler efficiency is η

K

≥

94 % (calculated to

DIN 4702-2).

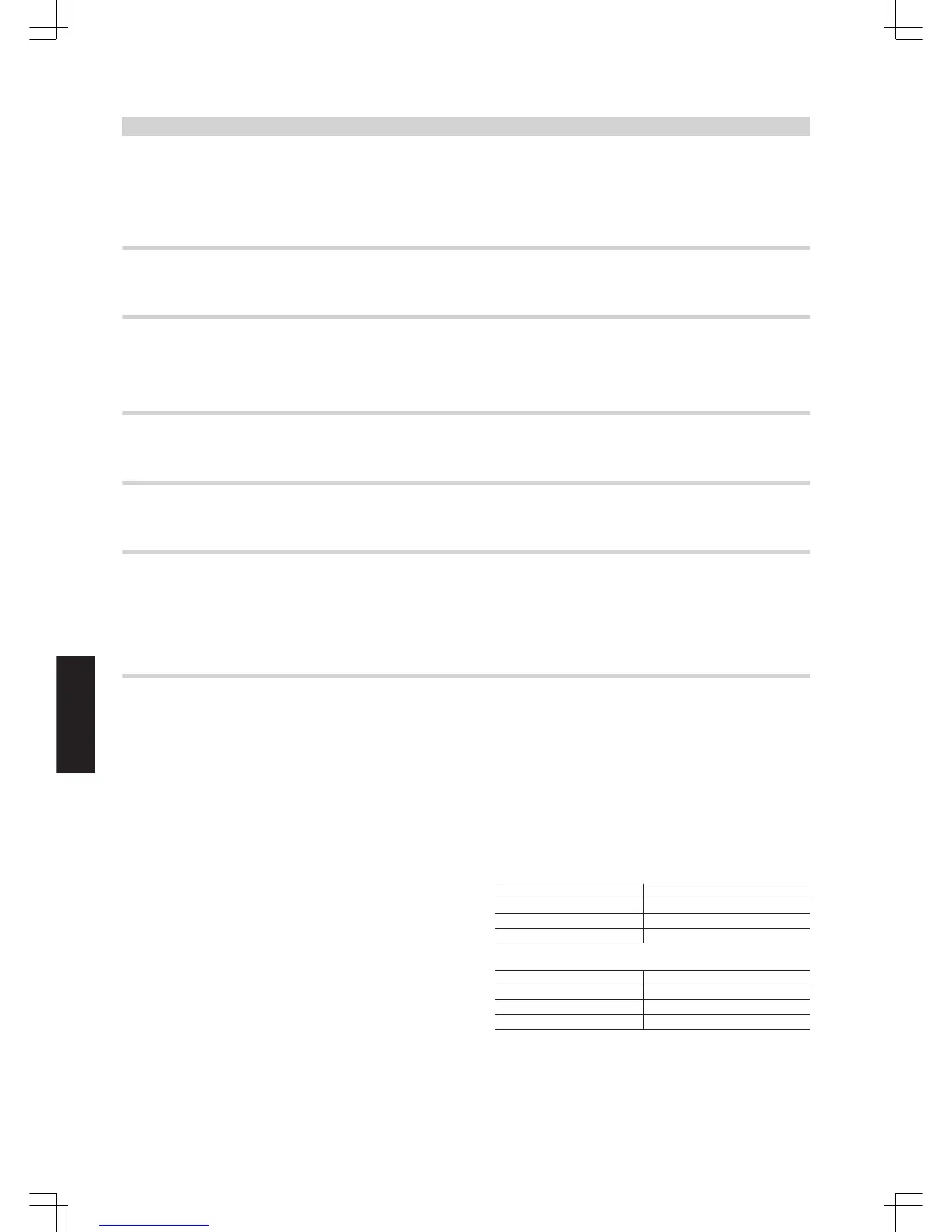

– The nitrogen oxide content of the flue gas in oil and combustion

systems:

For fuel oil EL:

Rated output in kW Emissions in mg/kWh

≤ 120

110

> 120 ≤ 400

120

> 400 185

For natural gas:

Rated output in kW Emissions in mg/kWh

≤ 120

60

> 120 ≤ 400

80

> 400 120

■ 1st BImSchV, paragraph 11a

Oil and gas combustion systems from 10 MW to 20 MW: Single

combustion systems with a combustion output between 10 and

< 20 MW may only be operated, if the emission values in the follow-

ing table (as average values over half an hour) are not exceeded:

Appendix

(cont.)

76

VIESMANN

OIL/GAS BOILERS

12

5822 426 GB

Loading...

Loading...