Operating and Assembly Instructions

Dispenser RD-EC26 / 27

Version 1.2

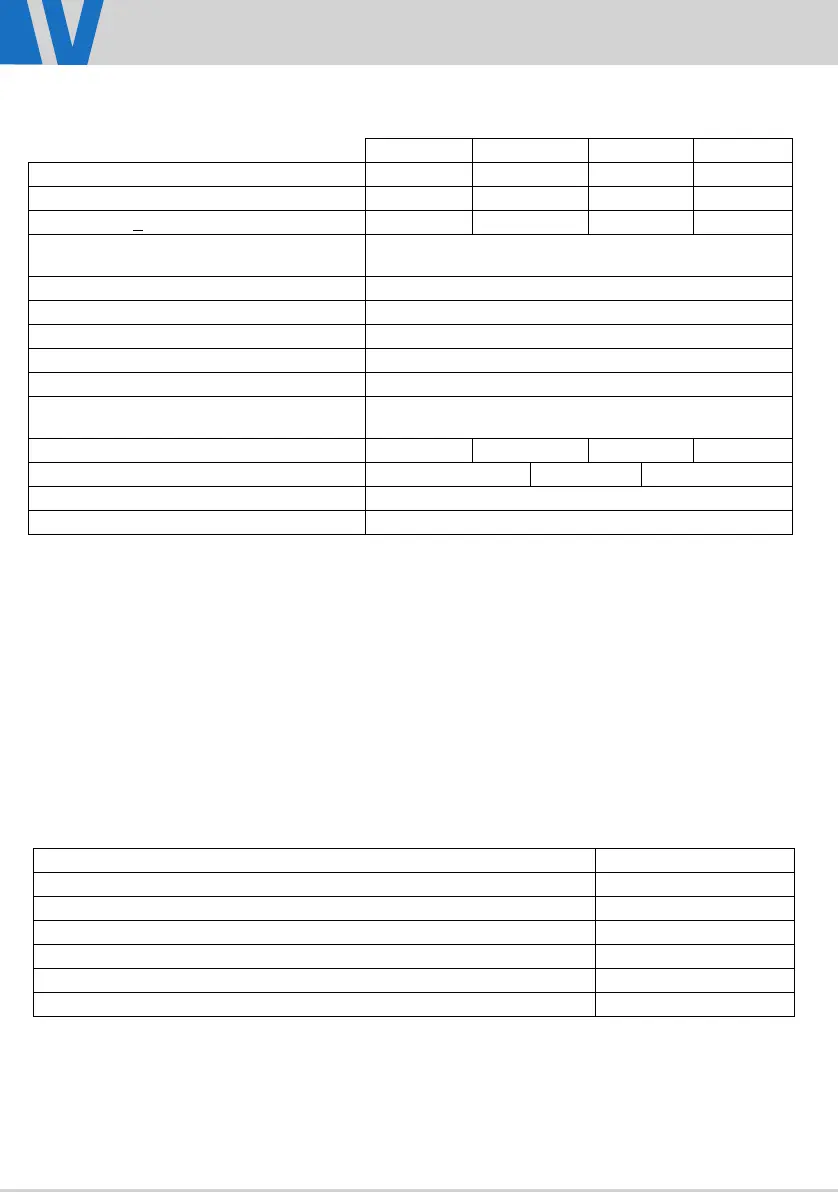

7.2 Technical data

7.3 Materials used

Dispenser type 4RD6 3RD8 3RD10 3RD12

Dosing volume, approx. ml/rev. 0.12 0.35 1.1 1.7

Minimum metering volume ml *1 0.005 0.02 0.05 0.1

Accuracy ml +, absolute *1 0.0006 0.002 0.0055 0.011

Admission pressure, max. bar (inlet

pressure) *2 *6

20

Metering pressure *3 *6, max. bar 30

Metering pressure *4 *6, max. bar 20

Self-sealing *5 (see section 1.1) approx. 2 bar

Ambient operating conditions +10°to+ 40° Celsius (Ta), air pressure 1 bar

Medium temperature ° Celsius -20 to +80

Storage conditions / storage temperature °

Celsius

dry and dust-free / -10 to +40

Weight without drive, approx. grams 1020 1030 1220 1440

Necessary drive torque, Nm 1-3 2-4 3-5

Maximum speed, rpm 125

Maximum permissible torque, Nm 8

*1 Reference medium approx. 1000 mpas. at 20°C

*2 For both pumping directions

*3 Preferred pumping direction: from 1A to 1B (anti-clockwise rotating dispenser, Fig. 14)

*4 Opposite to preferred pumping direction: from 1B to 1A (anti-clockwise rotating dispenser,

Fig. 14)

*5 Max. dosing pressure and self-sealing decrease as viscosity decreases. Consult

manufacturer.

*6 Maximum value, depending on the medium

There is FDA approval for the non-stick coating.

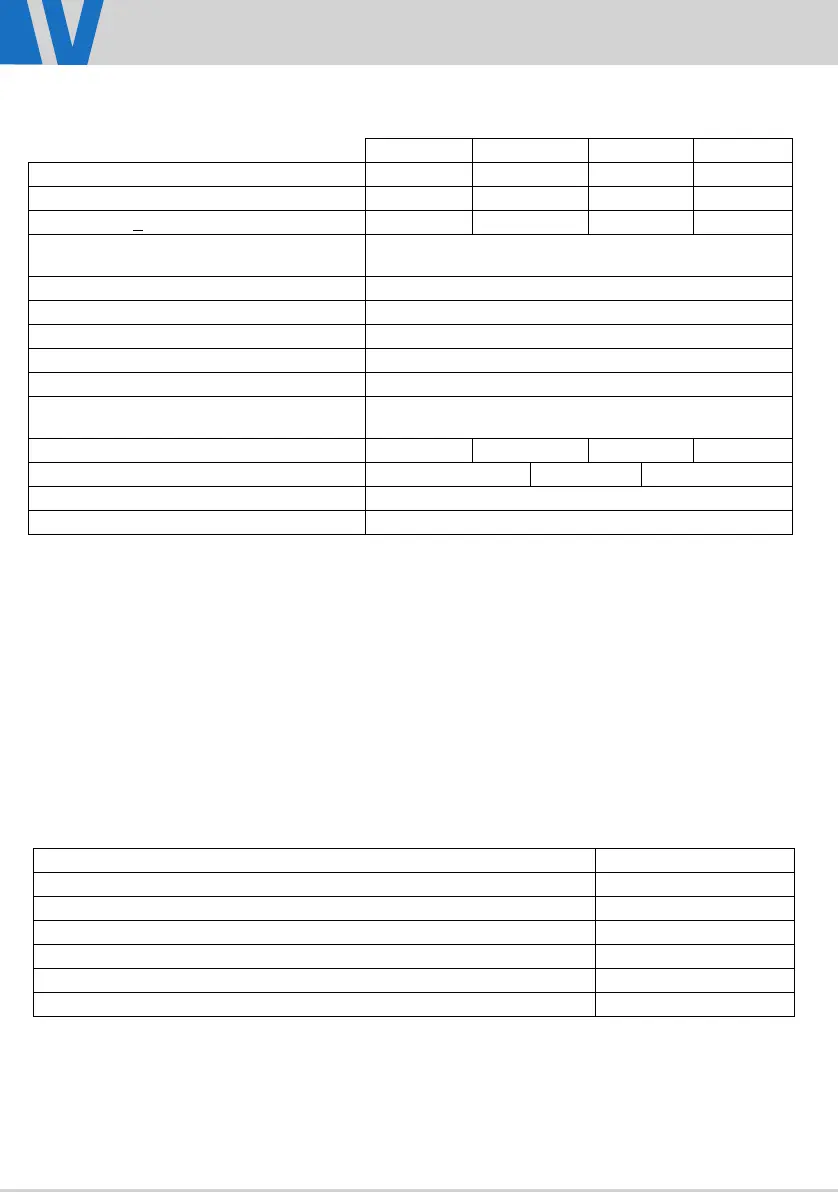

Components in contact with product

Non-stick coating in inner dispenser housing PFA

Housing, screws, washers, stator housing, bearings Stainless steel

Sealing washers PTFE

O-rings Viton ®*

Rotary shaft seal (L), high pressure rotary shaft seal PTFE 40% GF

Rotor coating Hard chromium plated

Rubberised flex-shaft VisChem

Stator, see page 24

* Viton ® is a DuPont brand

Loading...

Loading...