VOLLMER WERKE

Operating instructions

Issue: 01

MAP 200 / 400

Page: 13-1

13 DIAGNOSIS

This machine is equiped of an error display system.

Interventions and the diagnosis on the machine should be carried out only by qualified personal.

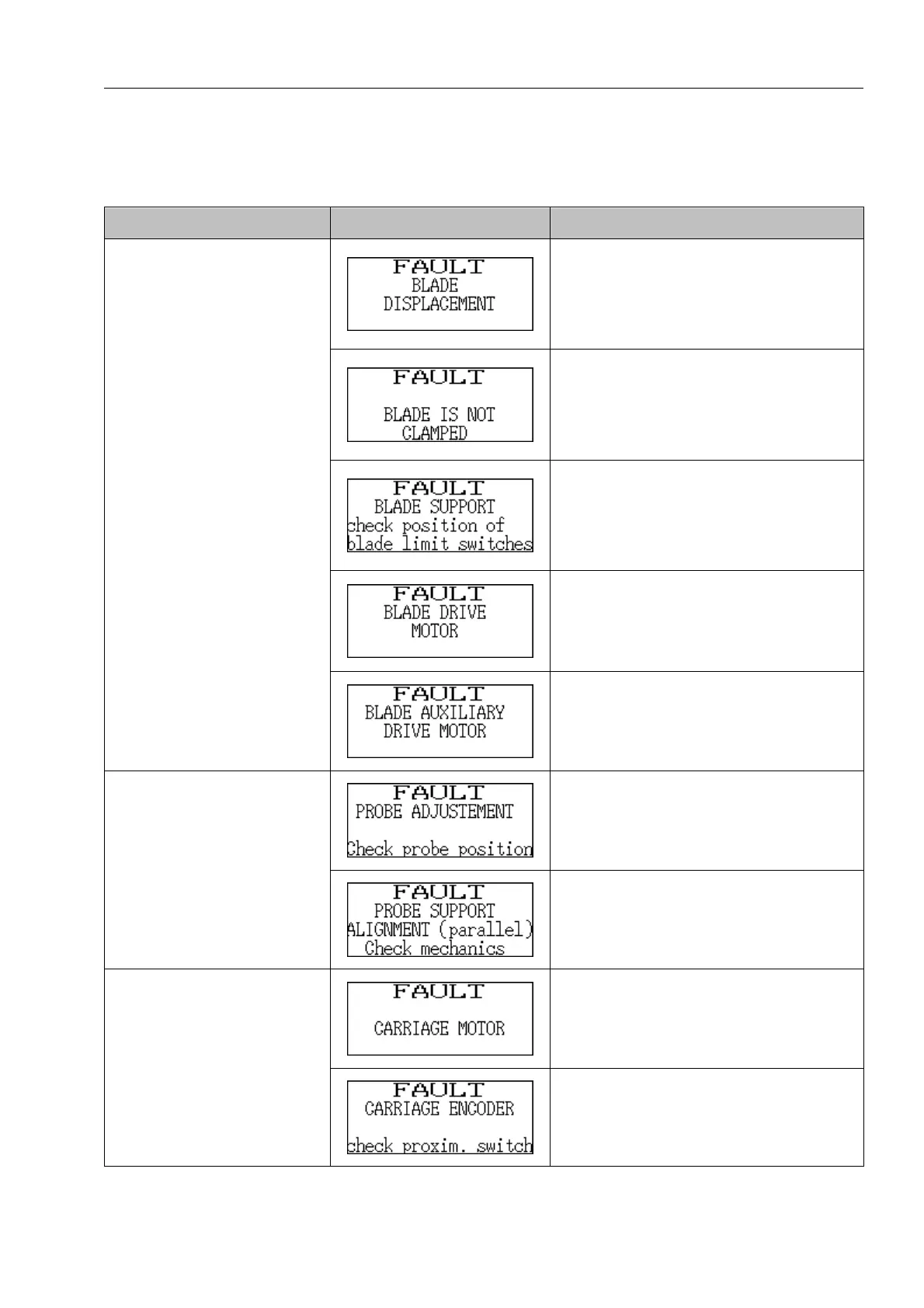

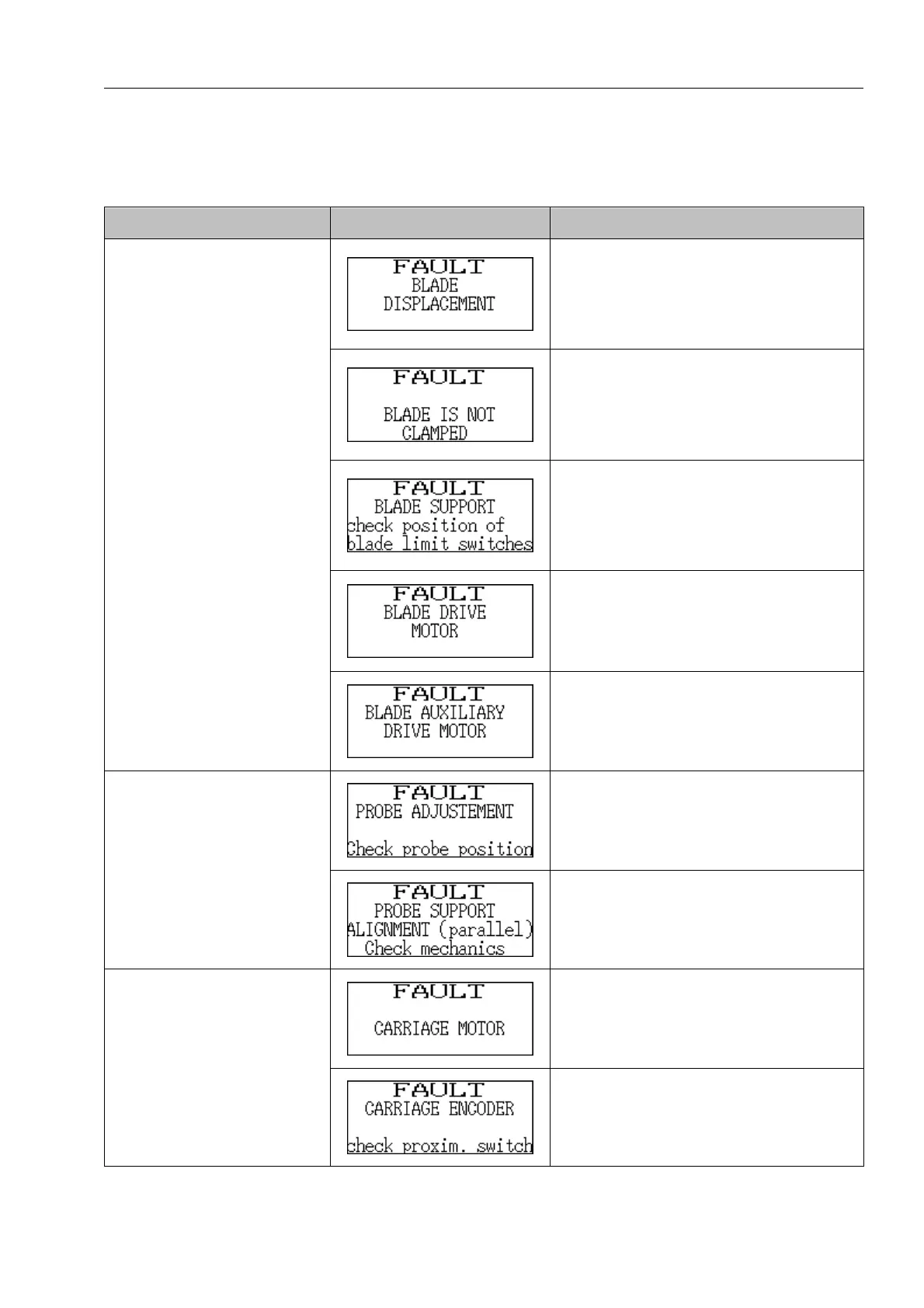

Default Display Diagnosis

• Make sure that the saw blade has

been tightened between the guiding

devices, if not, search the reason

and solve at source.

• Adjust the compressed air pres-

sure.

• Adjust the compressed air pres-

sure.

• Incorrect adjustment, activate the

selector again.

• Defective selector, replace the se-

lector.

• Adjust the position of limit switches

on the exterior sides of the blade

guides.

• Make sure the limit switches work

correctly, if necessary replace

them.

• Adjust the contactor.

• Adjust the motor commutator.

• Adjust the motor.

The saw blade stays immobile.

(Only on MAP400)

• Adjust the contactor.

• Adjust the motor commutator.

• Adjust the motor.

• Adjust the sensor position at the

level of the linear guide, the dis-

tance between the sensor surface

and the saw blade should rise to

1,5 mm maximum.

The sensor can not be reset.

• Make sure the sensor support is

parallel with the blade guide, if

necessary adjust.

• Adjust the circuit breaker.

• Adjust the overheating relay.

• Adjust the cabling.

• Adjust the motor.

The carriage stays immobile.

• Adjust the inductive proximity sen-

sor, if necessary replace it.

Loading...

Loading...