Operation

Loading and transporting

BA RD18 en 01

59

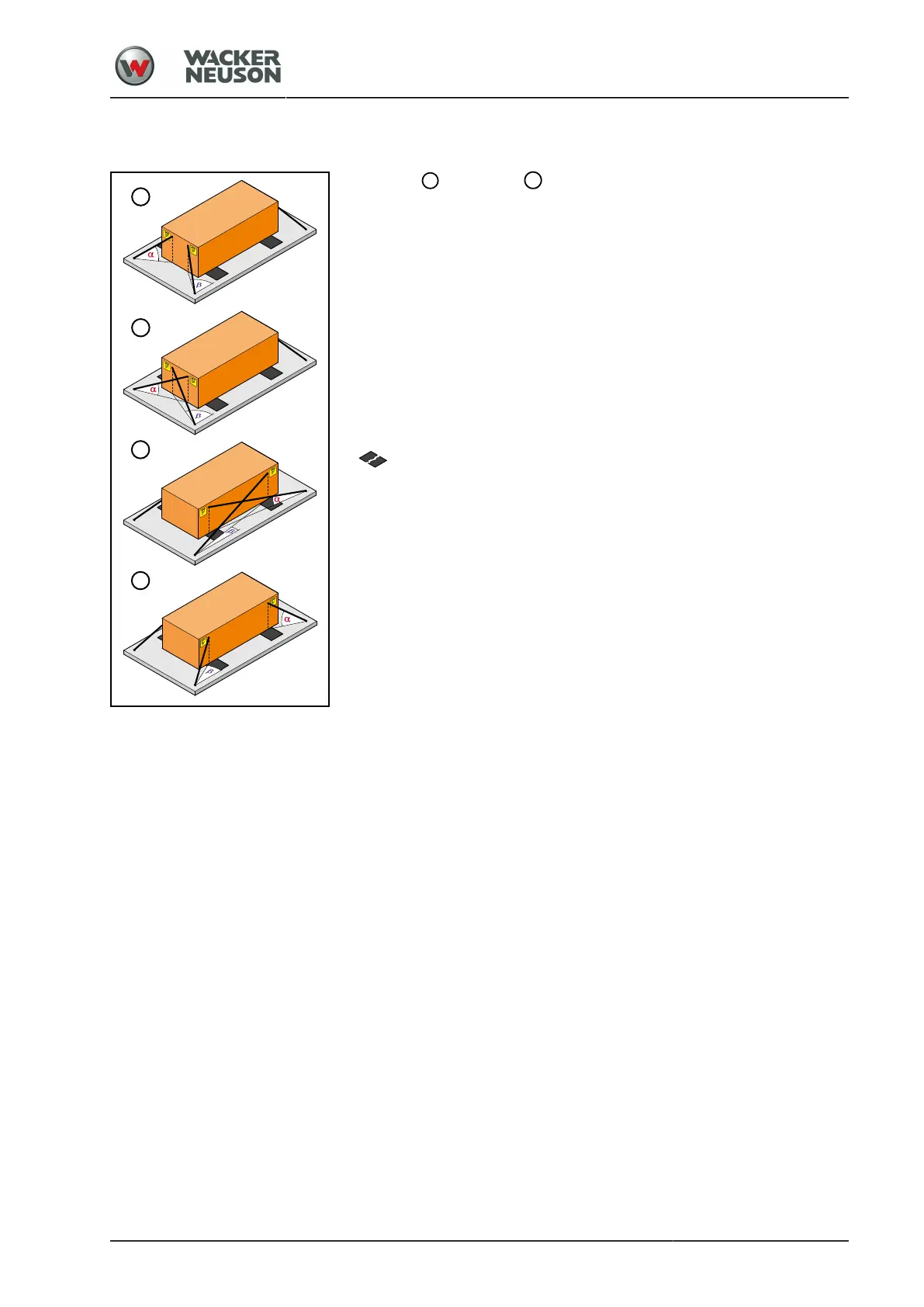

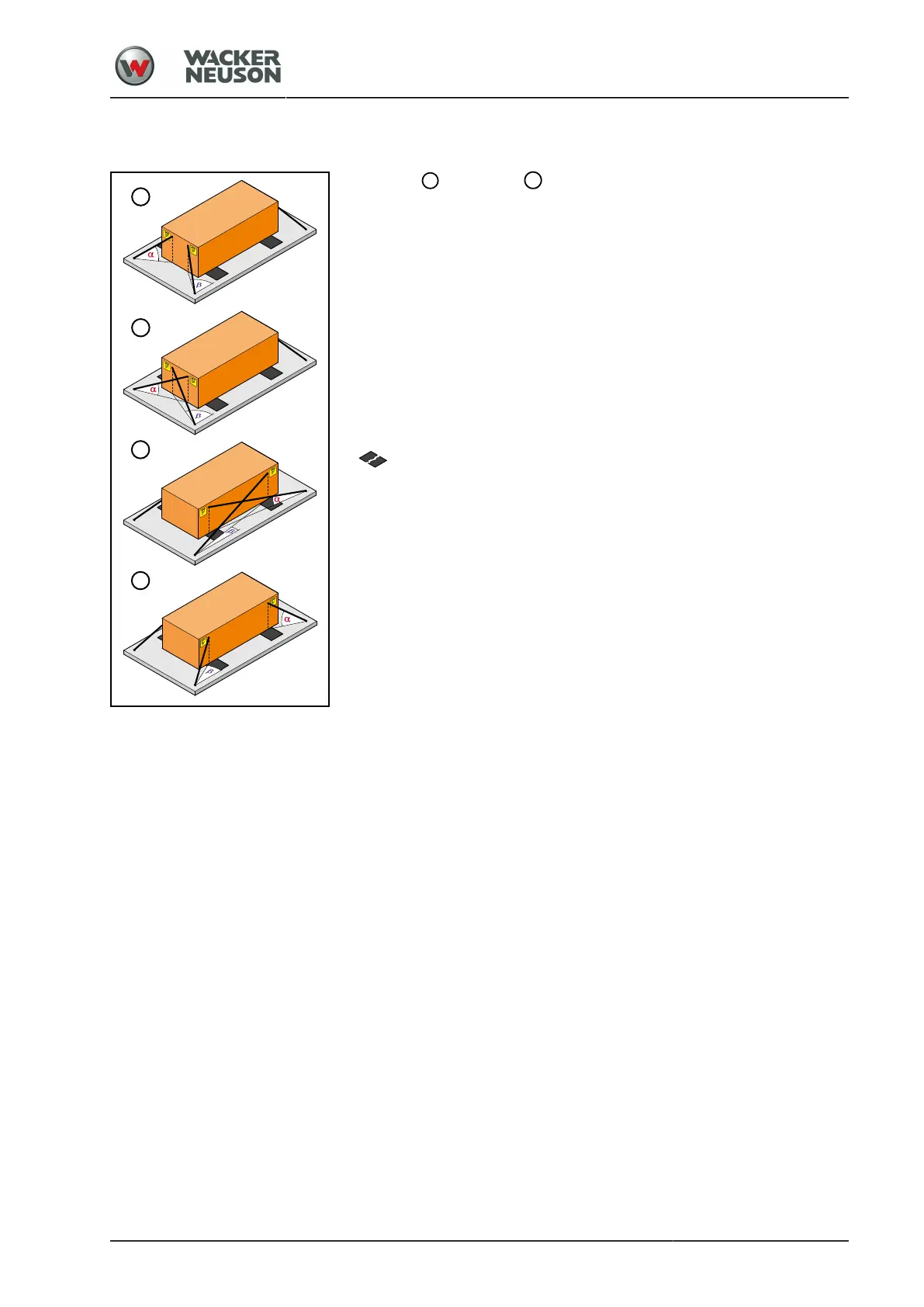

Load securing

Special notes

■

Variant

and variant

may be combined. The lashing devices

must not necessarily be arranged crosswise.

■

Do not use any lashing device unless it is of sufficient dimension,

bears the corresponding marking, and has been subjected to a valid

inspection.

■

Lash the machine with appropriate lashing devices onto the loading

area, using only the marked lashing eyes.

■

Observe the load for the lashing point(s) at the vehicle/load platform

and at the load/roller. Do not overload the lashing points with a

tensioning device (see the loading chart).

■

To increase load safety, use additional precautions for securing the

load including, e.g., wheel stop wedges, or a positive fit at the goose-

neck.

NOTE

Store the machine on the load platform, placing two

continuous and clean strips of anti-slide mats (grammage

approx. 10 kg/m², loadable up to 630 t/m², 10 mm thick,

friction factor µ ≥ 0.6) under every roller drum/tyre.

Loading...

Loading...