3 Maintenance procedures

This section provides the maintenance guidelines and procedures necessary to maintain the

device's performance.

Keep to a maintenance schedule, and perform maintenance as required and described in this

section.

3.1 Maintenance schedule

The following table lists periodic maintenance schedules that ensure optimum instrument

performance.

The maintenance frequencies shown apply to instruments that normally receive moderate use.

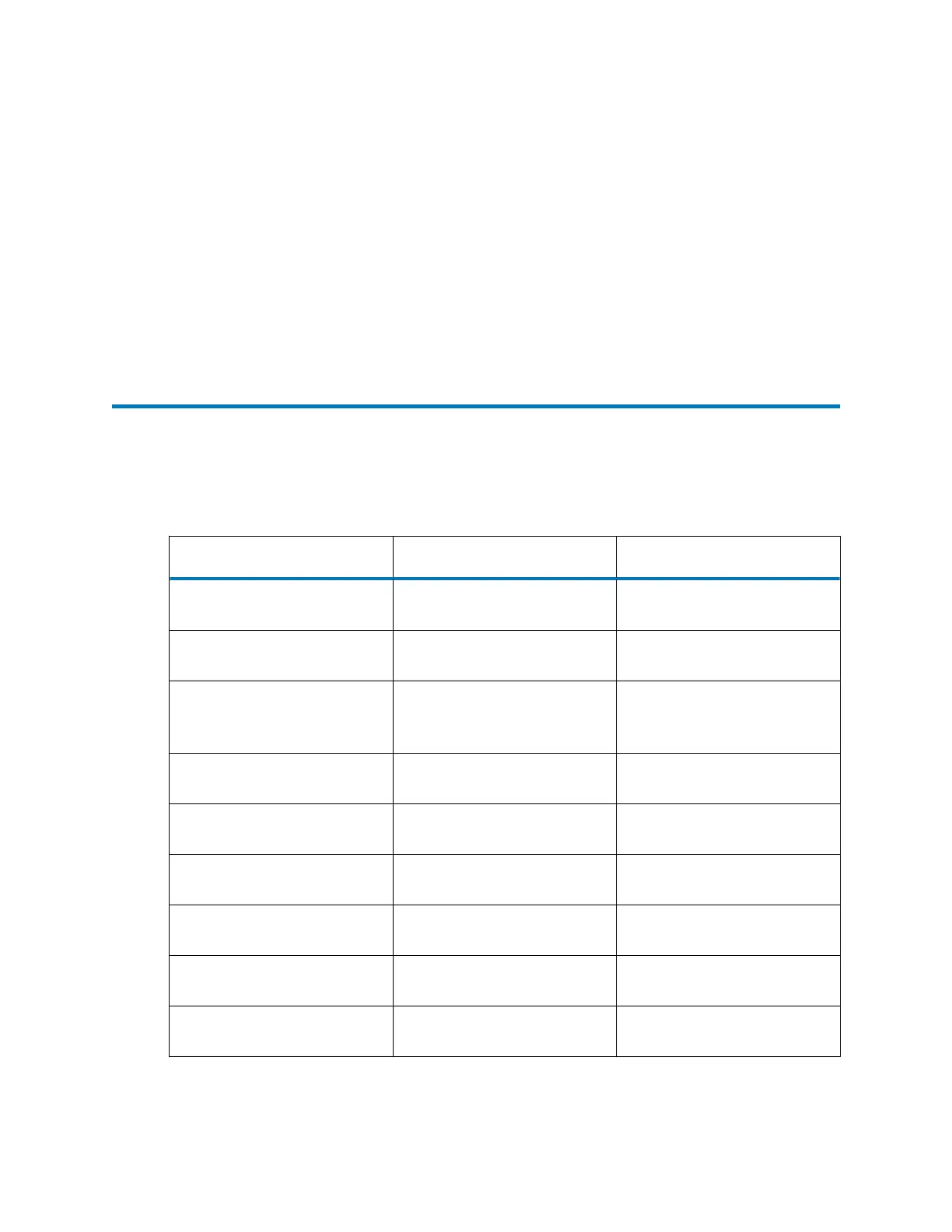

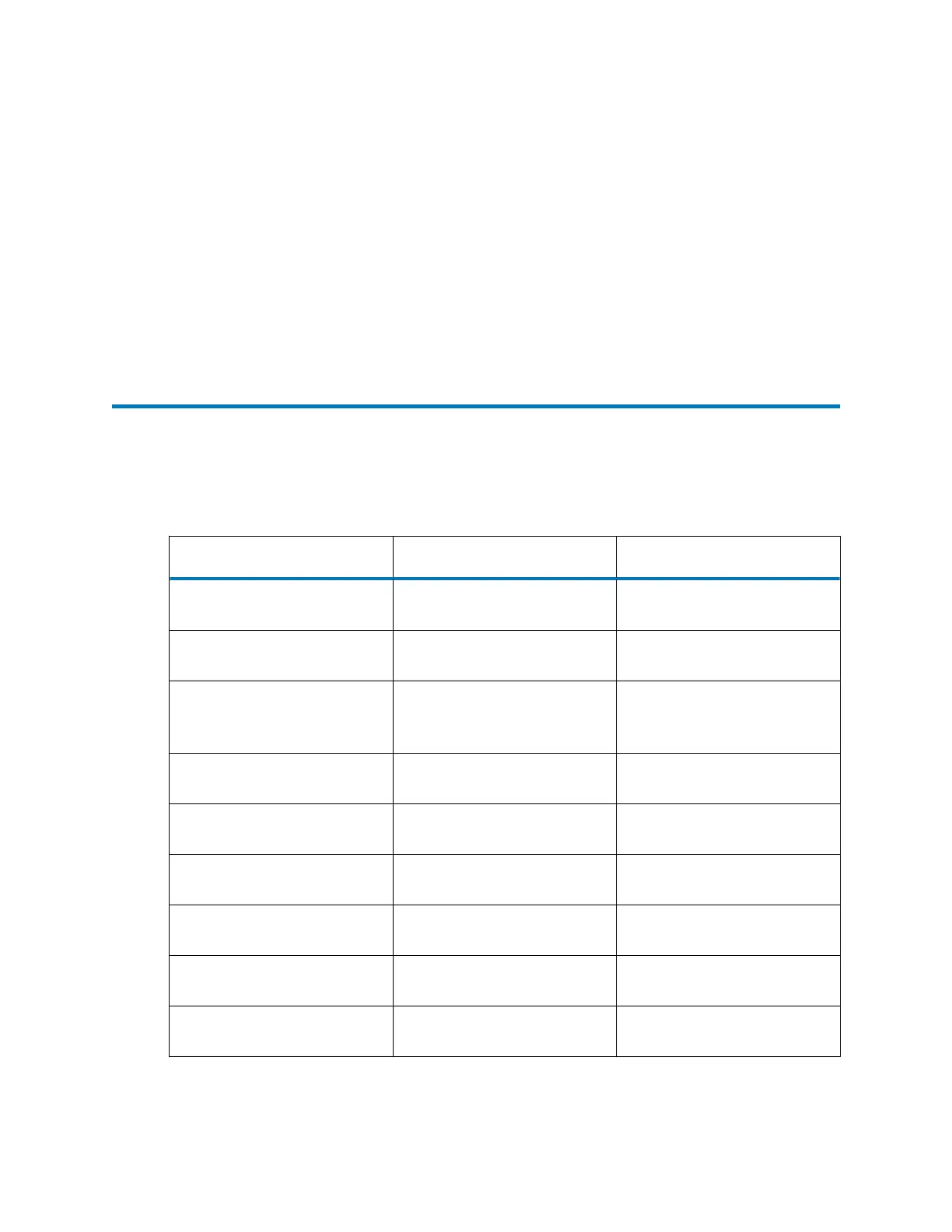

Table 3–1: Maintenance schedule

Procedure Frequency Additional information

Replace the probe capillary

assembly

When sensitivity decreases to

unacceptable levels

See Replacing the probe

capillary assembly (Page 52).

Replace the aperture disc As required See Replacing the aperture

disc (Page 32).

Replace or refit the source

enclosure o-ring

As required See Replacing or refitting the

source enclosure o-ring (Page

31).

Clean the source components When sensitivity decreases to

unacceptable levels

See Cleaning the source

components (Page 35).

Replace the air filters Annually See Replacing the air filters

(Page 55).

Clean the instrument case As required See Cleaning the exterior of

the equipment (Page 55).

Inspect and adjust the rotary

backing pump's oil level

Weekly See Maintaining the rotary

backing pump’s oil (Page 61).

Empty the exhaust trap bottle

in the instrument exhaust line

Check daily, empty as required See Emptying the source

exhaust trap bottle (Page 60).

Change the rotary backing

pump oil

Annually See Maintaining the rotary

backing pump’s oil (Page 61).

August 20, 2021, 715005003 Ver. 04 (Previously released as Revision C)

Page 26

Loading...

Loading...