Rotary indexing ring NR

Mounting

8 Mounting

8.1 Prerequisites for mounting

The motor must remain accessible for service and maintenance work.

Prior to mounting, the anti-corrosion and any pollution must be removed with a standard solvent.

NOTICE

DAMAGE TO SHAFT SEALING RINGS

Failure to follow these instructions can result in equipment damage.

■

Avoid any contact of the sealing lips of the shaft sealing rings with the solvent.

Prior to mounting, verify that the dimensions of the installation site and construction conditions meet

the requirements and the dimensions specified in these mounting instructions and the applicable

documents.

■

Verify that the supporting base is level and rigid.

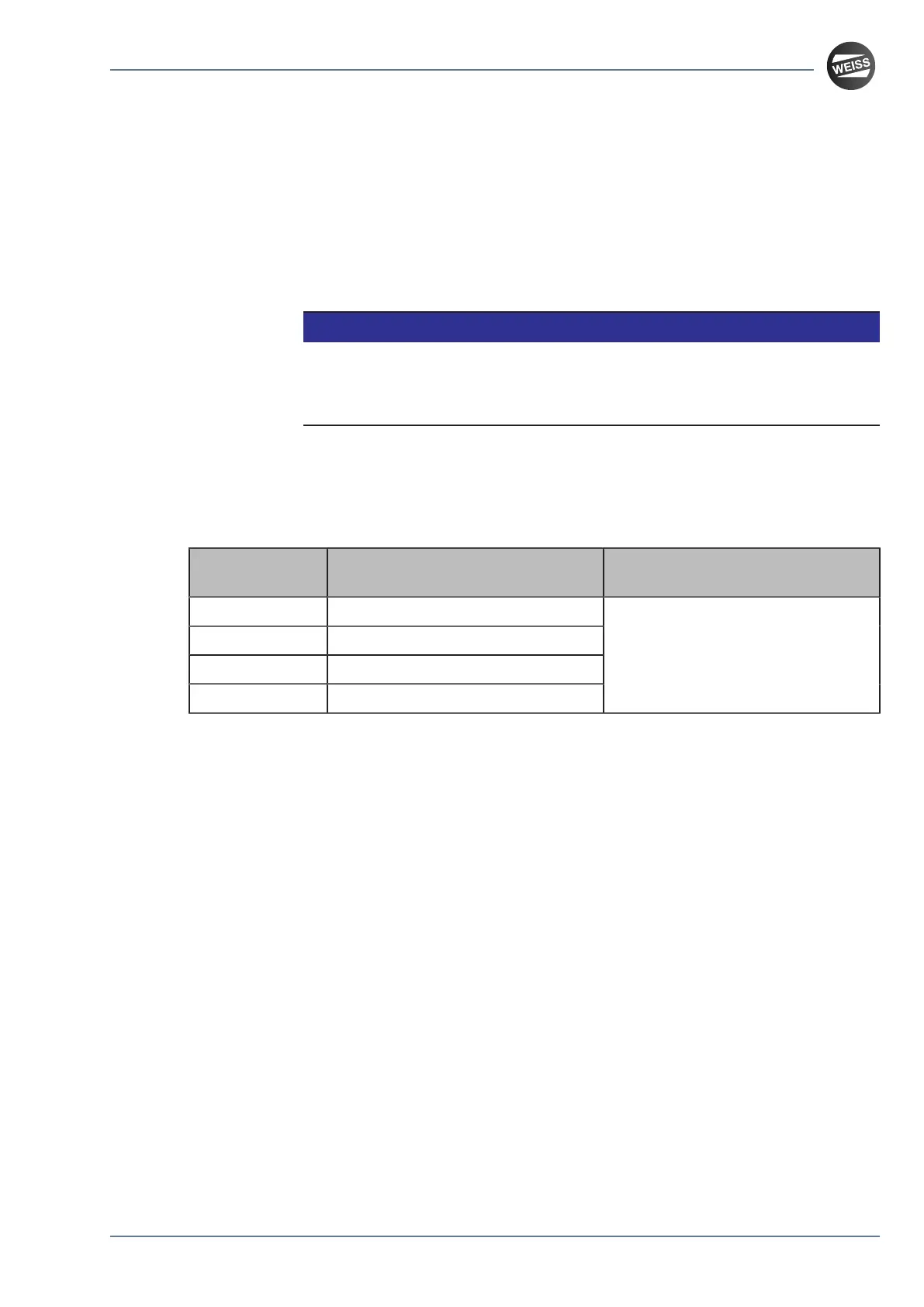

Product type Maximum permissible flatness error Maximum permissible surface

roughness

NR0750Z 0.090 mm

NR1100Z 0.105 mm

NR1500Z 0.125 mm

NR2200Z 0.175 mm

Rz 6.3 ... Rz 16

■

Verify that the supporting structure at the installation site has a sufficient structural strength to carry

the weight of the product and of all loads.

■

Verify that the motor is easily accessible for service and maintenance work.

■

Verify that there is a minimum distance of 100 mm between the motor fan and other assemblies.

■

Verify that free convection for removing the hot air is not obstructed.

8.2 Equipment and tools

The following is required for mounting:

■

Set of hex keys

■

Set of wrenches

■

Set of screwdrivers

■

Torque wrench

■

Ball pane hammer

■

Plastic hammer

■

Cotter pin punch (for mounting the parallel pins)

Mounting instructions_062019_1.0_en

29 / 62

Loading...

Loading...