COOLING

SYSTEM

FRESH

WATER

COOLING

CIRCUIT

Fresh water (antifreeze)

is

moved

through

the engine

by

a

belt

driven

circulating

pump,

absorbing heat

from

the

engine.

Some

of

the

coolant by-passes

the

thermostat

to

maintain

circulation

in

the

engine

and

is

drawn

through

the

heat

exchanger.

The engine operating temperature

rises

and

the

thermostat reacts

to

this

and

starts

to

open

allowing

more

coolant

to

flow

through

the

heat

exchanger.

The thermostat

opening

will

change

as

it

gains

control of

the

engine

operating temperature

by

allowing

more

or

less coolant

flow

through

it.

ENGINE

COOLANT

WESTERBEKE recommends a

mixture

of

50%

antifreeze

and

50%

distilled

water.

Distilled water

is

free

from

the

chemicals that can corrode internal engine surfaces.

The antifreeze performs a double

duty.

It

allows

the

engine

to

run

at

proper temperatures

by

transferring heat

away

from

the

engine

to

the

coolant

and

lubricates and protects

the

cook

ing

circuit

from

rust

and

corrosion,.

Look for a good quality

antifreeze that contains Supplemental Cooling Additives

(SCAs)

that

keep

the

antifreeze chemically balanced, crucial

to

long term protection.

NOTE:

Look

for

the

new

environmentally

friendly

long

lasting

antifreeze

that

is

now

available.

The recommended

50/50

mixture

will

protect the engine

against

the

most extreme temperature. The antifreeze

miX:ture

will

also

retard rust within

the

engine

and add

to

the

life of

the

circulating pump impeller

and

seals.

A proper

50/50 mixture

as

recommended will protect

the

engine coolant

to

temperatures

of-

40"F.

The coolant recovery tank

allows

for

the

expansion

and

con-

traction of

the

engines coolant

during

engine operation

with-

out introducing air

into

the

system.

This recovery

tank

is

provided

and

must be installed

oefore

operating the

engine.

NOTE:

This

tank,

with

its

sltort

run

oJ

plastcc

hose,

is

best

located

at

or

above

the

level

of

the

engine's

manifold.

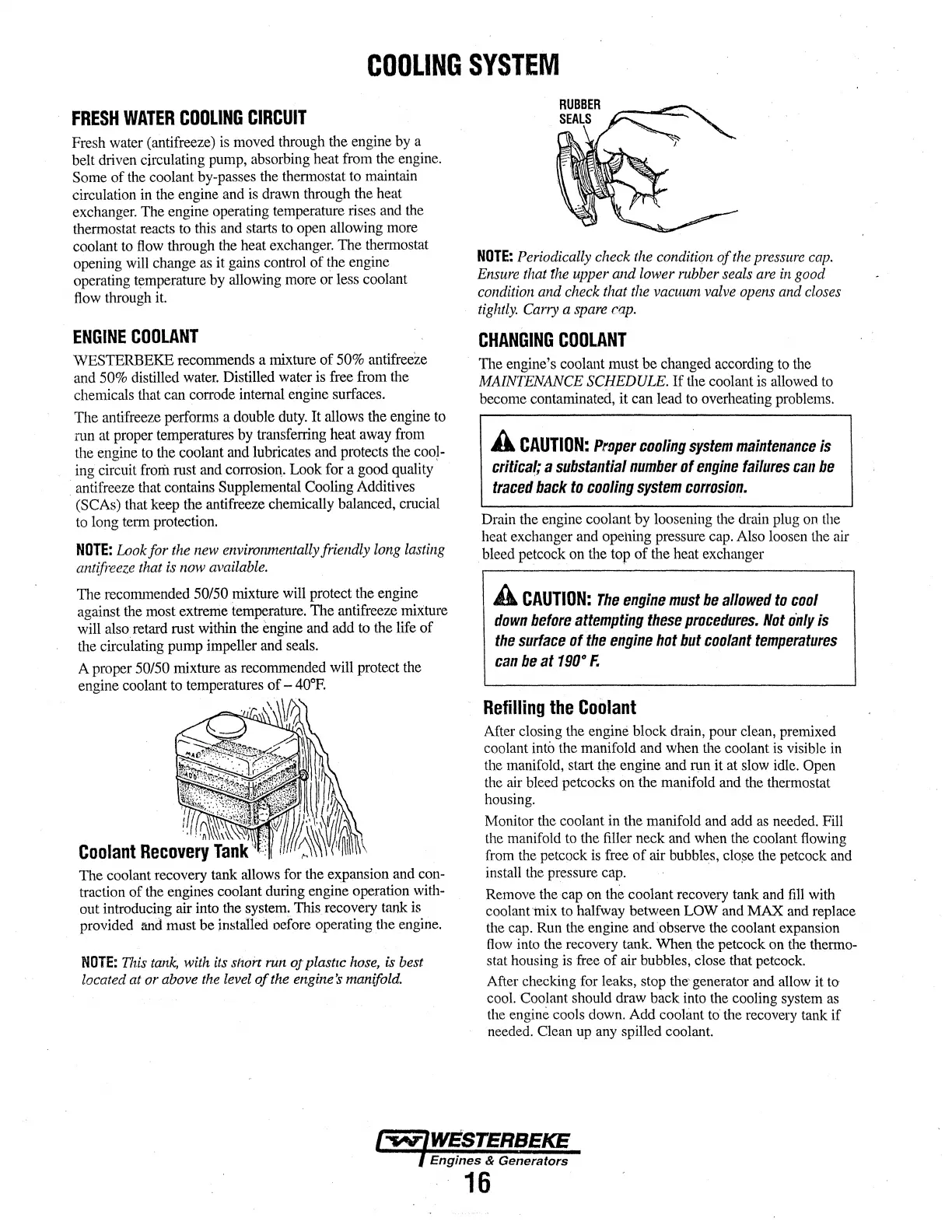

NOTE:

Periodically check

the

condition

of

the

pressure

cap.

Ensure

that

the

upper and lower

rubber

seals

are

in

good

condition

and check that

the

vacuum

valve

opens

and

closes

tightly.

Carry

a

spare

cap.

CHANGING

COOLANT

The engine's coolant must be changed

according

to

the

MAINTENANCE

SCHEDULE.

If

the

coolant

is

allowed

to

become contaminated, it can lead

to

overheating

problems.

A

CAUTION:

Proper

cooling

system

maintenance

is

critical;

a

substantial

number

of

engine

failures

can

be

traced

back

to

cooling

system

corrosion.

Drain the engine coolant

by

loosening

the

drain

plug

on

the

heat exchanger

and

opehing pressure

cap.

Also

loosen

the

air

bleed petcock

on

the

top of

the

heat exchanger

A

CAUTION:

The

engine

must

be

allowed

to

cool

down

before

attempting

these

procedures.

Not

only

is

the

surface

of

the

engine

hot

but

coolant

temperatures

can

be

at

190°

F.

Refilling

the

Coolant

After

closing the engine block

drain,

pour

clean,

premixed

coolant

into

the

manifold

and

when

the

coolant

is

visible

in

the

manifold,

start the engine

and

nm

it at

slow

idle.

Open

the

air

bleed

petcocks

on

the

manifold

and

the

thermostat

housing.

Monitor

the coolant

in

the manifold

and

add

as

needed.

Fill

the

manifold

to

the

filler

neck

and

when

the

coolant

flowing

from

the

petcock

is

free of air

bubbles,

clo~e

the

petcock

and

install

the

pressure

cap.

Remove

the

cap

on

th~

coolant

recovery

tank

and

fill

with

coolannnix

to

halfway

between

LOW

and

MAX

and

replace

the

cap.

Run

the

engine

and

observe

the

coolant

expansion

flow

into

the

recovery

tank.

When

the

petcock

on

the

thermo-

stat

housing

is

free

of air

bubbles,

close that

petcock.

After

checking

for

leaks, stop

the'

generator

and

allow

it

to

cool.

Coolant

should

draw back

into

the

cooling

system

as

the

engine

cools

down.

Add

coolimt

to

the

recovery

tank

if

needed.

Clean

up

any

spilled coolant.

Engines & Generators

16

Loading...

Loading...