GENERATOR

INFORMATION

USE

OF

ELECTRIC

MOTORS

The power required

to

start

an

electric motor

is

considerably

more

than

is

required to keep it running after it

is

started.

Some motors require

much

more current to start them than

others. Split-phase (AC) motors require more current

to

start,

under similar circumstances, than other types. They are

com-

monly used on easy-starting loads, such

as

washing

machines, or where loads are applied after the motor

is

started, such

as

small power tools. Because they require 5

to

7 times

as

much current

to

start

as

to run, their

use

should be

avoided, whenever possible,

if

the electric motor

is

to

be

driven

by

a small generator. Capacitor and repulsion-

induction motors require from 2

to

4 times

as

much current

to

start

as

to

run. The current required to start

any

motor

varies with the load connected to

it

An

electric motor con-

nected

to

an

air compressor,

for

example, will require more

current

than

a motor

to

which

no

load is connected.

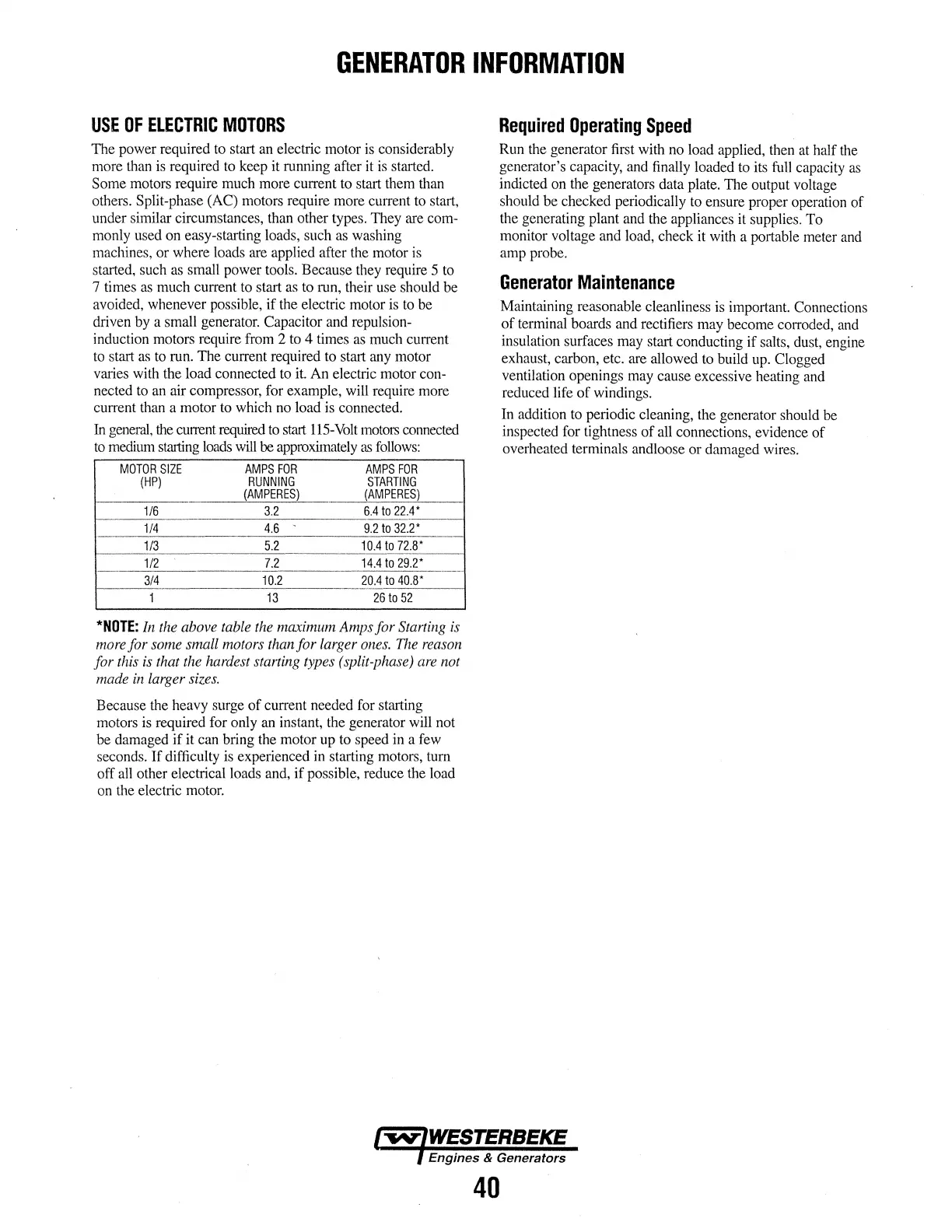

fu

general,

the

current

required

to

start

115-

Volt

motors

connected

to

medium

starting

loads

will

be

approximately

as

follows:

MOTOR

SIZE

AMPS

FOR

AMPS

FOR

(HP)

RUNNING

STARTING

(AMPERES)

(AMPERES)

1/6

3.2

6.4

to

22.4*

1/4

4.6

'

9.2

to

32.2*

1/3

5.2

10.4

to

72.8*

1/2

7.2

14.4

to

29.2*

3/4

10.2

20.4

to

40.8*

1

13

26

to

52

*NOTE:

In

the

above

table

the

maximum Amps for Starting

is

more

for some small motors

than

for larger

ones.

T11e

reason

for

this

is

that

the

hardest starting types (split-phase)

are

not

made

in

larger

sizes.

Because the heavy surge of current needed for starting

motors

is

required for only

an

instant, the generator will not

be

damaged if it

can

bring the motor

up

to speed in a

few

seconds.

If

difficulty

is

experienced

in

starting motors, tum

off

all

other electrical loads

and,

if possible, reduce the load

on

the electric

motor.

Required

Operating

Speed

Run the generator first with

no

load applied, then

at

half

the

generator's capacity,

and

finally loaded to

its

full

capacity

as

indicted on the generators data plate. The output voltage

should be checked periodically

to

ensure proper operation of

the generating plant and the appliances it supplies. To

monitor voltage and load, check it with a portable meter

and

amp probe.

40

Generator

Maintenance

Maintaining reasonable cleanliness

is

important. Connections

of

terminal boards and rectifiers may become corroded,

and

insulation surfaces may start conducting if salts, dust, engine

exhaust, carbon, etc. are allowed

to

build up. Clogged

ventilation openings

may

cause excessive heating and

reduced life

of

windings.

In addition to periodic cleaning, the generator should

be

inspected

for

tightness

of

all connections, evidence of

overheated terminals andloose or damaged

wires.

Loading...

Loading...