ENGINE

ADJUSTMENTS

NOTE:

WESTERBEKE

recommends

that

the

following engine

adjustments

be

performed by a competent

engine

mechanic.

the

information

below

is provided

to

assist

the

mechanic.

VALVES

VALVE

CLEARANCE

It

is

routine

maintenance

to

adjust the valve clearance after

the

first

fifty

hours

of

operation.

Valve

clearance adjustment

must

be

performed

when

the

engine is cool

and

the

piston

must

be

the

top

dead center of

the

compression stroke.

Perform

the

following_

adjustment

steps:

1.

Remove

the

fuel

pump

and

filter assembly

from

the

cylinder

head

cover.

Unbolt

the

coil and

move

it out of

the

way.

This

should

give

good access

to

the valves

behind

the

covet.

2.

Remove

the

cylinder

head

cover ..

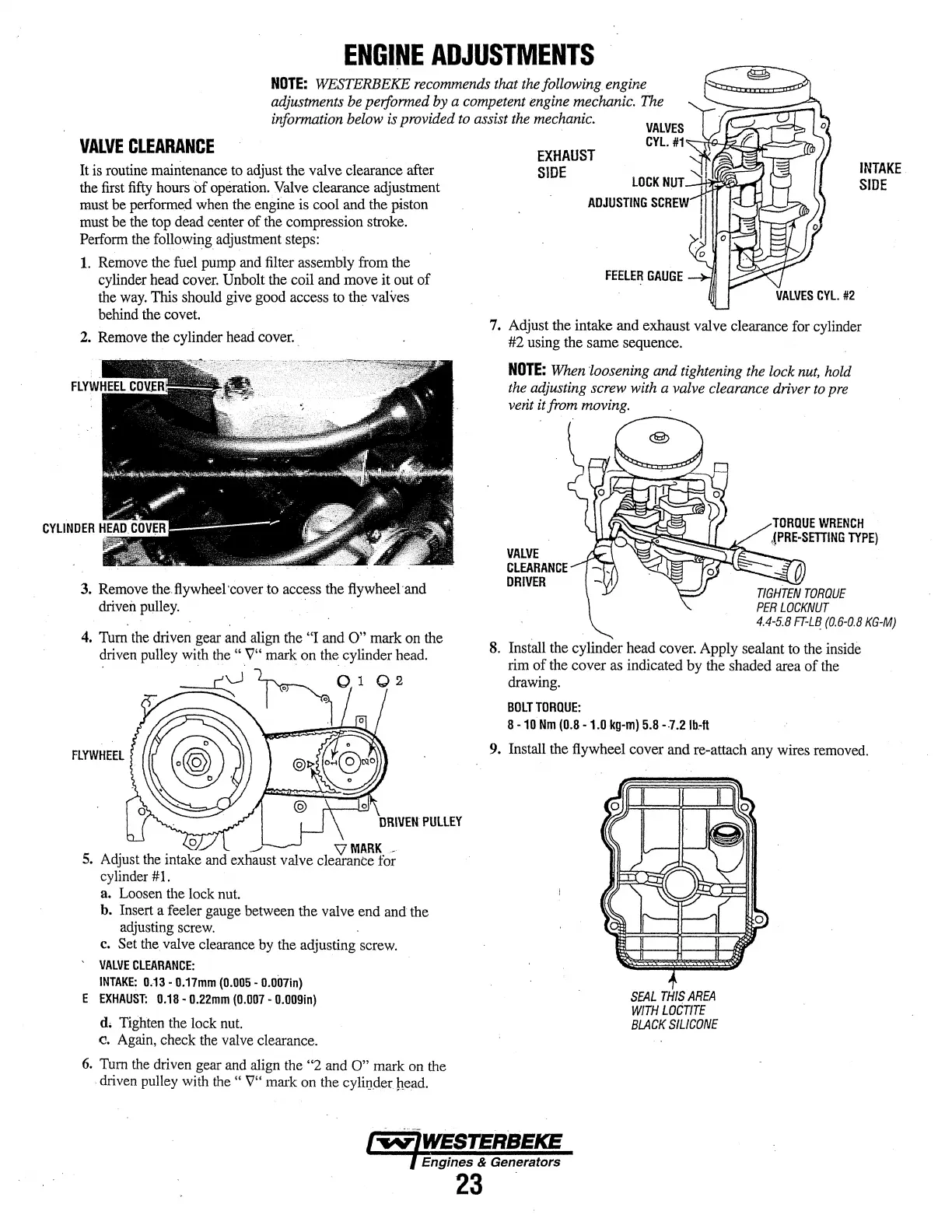

3.

Remove

the.flywheei·coverto access the flywheei·and

driven

pulley.

· ·

FLYWHEEL

. .

0

~

VMAA~-

5.

Adjust

the

mtake

and

exhaust valve clearance for

cylinder

#I.

a.

Loosen

the

lock

nut.

b.

Insert

a feeler

gauge

between

the valve

end

and

the

adjusting

screw.

c.

Set

the

valve

clearance

by

the

adjusting

screw.

VALVE

CLEARANCE:

INTAKE:

0.13

•

0.17mm

(0.005

•

0.007in)

E

EXHAUST:

0.18

•

0.22mm

(0.007

•

0.009in)

d,

Tighten

the

lock

nut.

c.

Again,

check

the

valve

clearance.

6.

Tum

the

driven

gear

and

align

the

"2

and

0"

mark

on

the

·driven

pulley

with

the

"

'\7"

mark

on

the

cyliiJder

head.

EXHAUST

SIDE

CYL.

#1~~~~:=::=;'1ib

ADJUSTING

SCREW

FEELER

GAUGE

INTAKE

SIDE

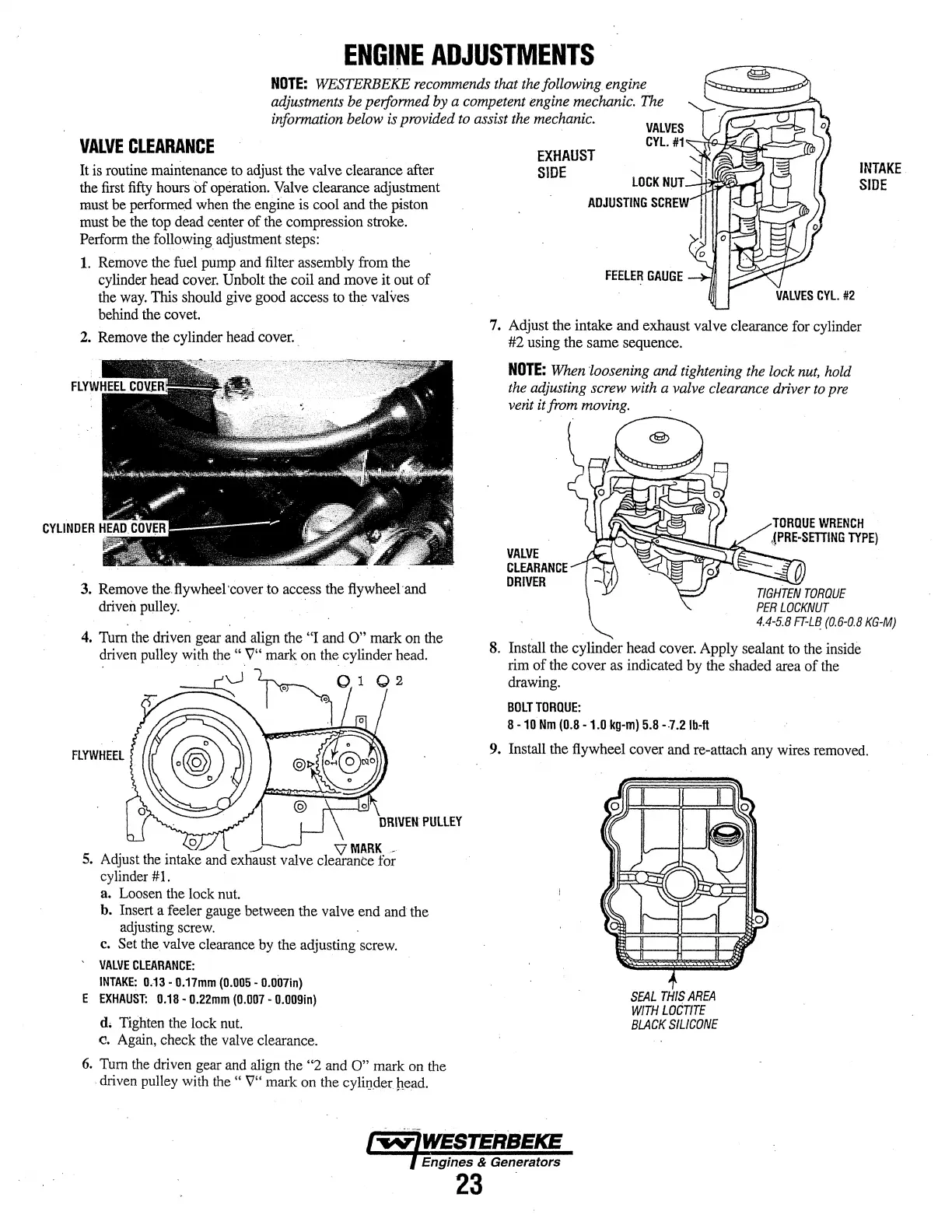

7.

Adjust the intake and exhaust valve clearance

for

cylinder

#2 using

the

same sequence.

NOTE:

When

'loosening

and tightening

the

lock

nut,

hold

the

adjusting screw

with

a valve clearance driver

to

pre

vent it

from

moving.

VALVE

CLEARANCE

DRIVER

TIGHTEN

TORQUE

PER

LOCKNUT

4.4·5.8

FT-LB_

(0.6-0.8

KG·M)

8.

Install the cylinder head

cover.

Apply sealant

to

the

inside

rim

of the cover as indicated by

the

shaded

area

of

the

drawing.

BOLT

TORQUE:

8-10

Nm

(0.8

-1.0kg-m)

5.8

--7.21b"ft

9. Install the flywheel cover and re-attach any wires

removed.

SEAL

THIS

AREA

WITH

LOCTITE

BLACK

SILICONE

Engines & Generators

23

Loading...

Loading...