ProTechTPS Total Protection System Manual 26710V1

12 Woodward

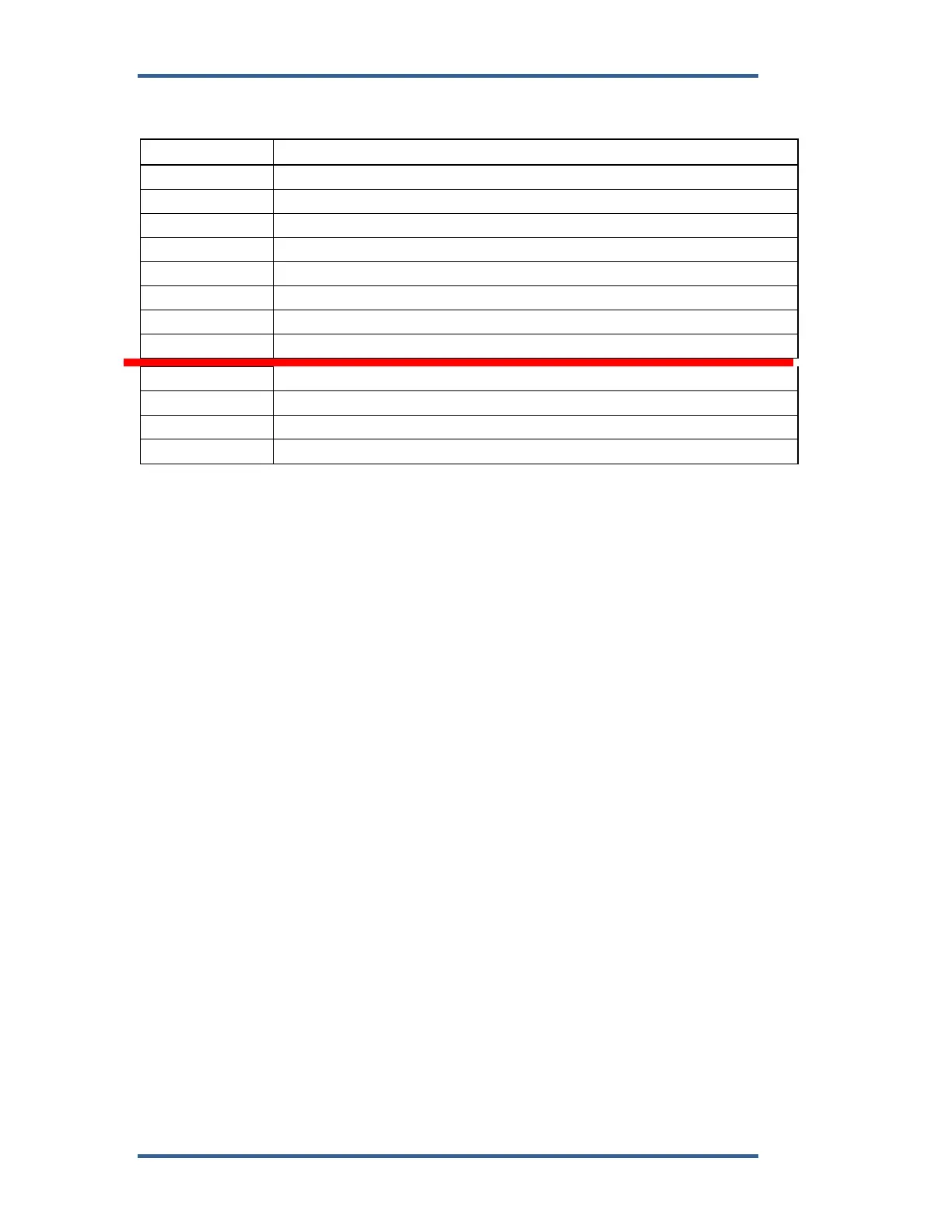

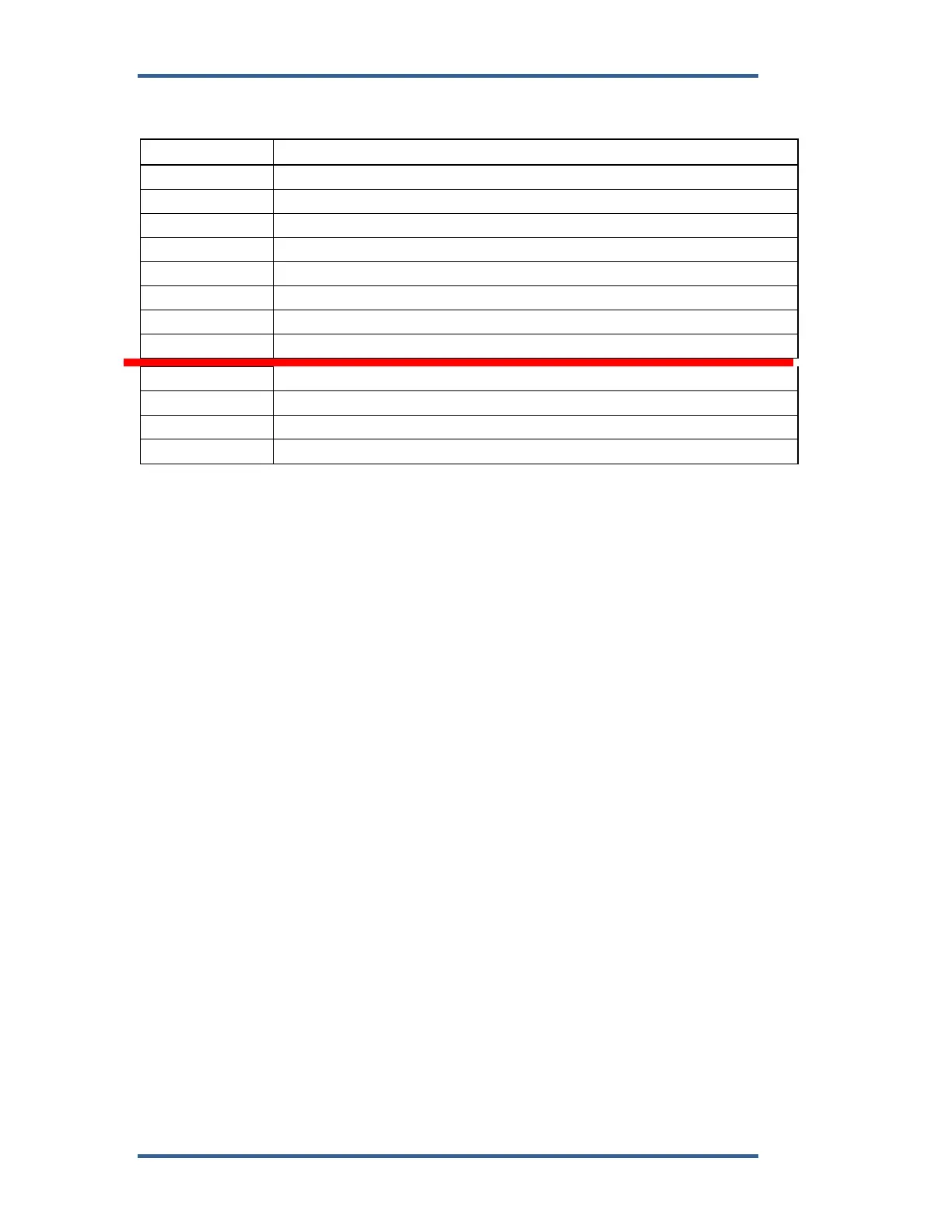

The following table shows the various hardware configurations (mounting

options, power supplies, and trip relay options) available:

PartNumber Description

8237‐1602 ProTechTPS,BulkheadMount,HV/LV,IndepRelay,VotedInput

8237‐1603 ProTechTPS,BulkheadMount,HV/HV,IndepRelay,VotedInput

8237‐1604 ProTechTPS,BulkheadMount,HV/LV,VotedRelay,VotedInput

8237‐1605 ProTechTPS,BulkheadMount,HV/HV,VotedRelay,VotedInput

8237‐1606 ProTechTPS,PanelMount,HV/LV,IndepRelay,VotedInput

8237‐1607 ProTechTPS,PanelMount,HV/HV,IndepRelay,VotedInput

8237‐1608 ProTechTPS,PanelMount,HV/LV,VotedRelay,VotedInput

8237‐1609 ProTechTPS,PanelMount,HV/HV,VotedRelay,VotedInput

5437‐1128 SpareModulefor8237‐1604,1608

5437‐1129 SpareModulefor8237‐1605,‐1609

5437‐1130 SpareModulefor8237‐1602,‐1606

5437‐1131 SpareModulefor8237‐1603,‐1607

Table 1-1. Available ProTechTPS Models

Applications

The ProTechTPS is designed to be applied as a safety system for any size

steam, gas, or hydro turbine, reciprocating engine, or plant process equipment.

The device's fast response time (8–26 milliseconds depending on model and

configuration), 0.5 to 32 000 rpm speed range, and integrated overspeed and

acceleration detection/protection functionality, make it ideal for applications on

critical low-speed or high-speed rotating motors, compressor, turbines or

engines. This standalone safety device accepts 10 discrete or analog inputs per

module (30 total) and one speed (MPU or PROX) input (3 total). Each

ProTechTPS module provides 3 programmable relay outputs (9 total) and an

analog speed output (3 total) in addition to the trip relay outputs. Configurable

logic allows the customization required to meet specific application requirements

to ensure plant protection.

The ProTechTPS utilizes a triple modular redundant architecture and 2-out-of-3

voting logic to accurately determine unsafe conditions and ensure that no single-

point failure will affect system reliability or availability. With this design, system

failures (switches, transducers, modules) are detected, annunciated, and allowed

to be repaired or replaced while the monitored system continues to operate

on-line.

Alternatively, this standalone safety device can be configured to protect any plant

system or device, and report the system’s device’s status to the plant DCS. The

ProTechTPS control’s versatile inputs, outputs, programming environment, and

communications make it ideal as a safety protection device for use in small

applications that could possibly reach an unsafe state or condition and that must

communicate directly to the plant DCS. The ProTechTPS is designed for critical

applications where both personnel safety and unit availability (operation run time)

is a concern or necessity.

The ProTechTPS is certified as an IEC61508 SIL-3 (Safety Integrity Level 3)

safety device and can be applied as a stand-alone IEC61508-based device or

within an IEC61511-based plant safety system.

Loading...

Loading...