Pre-Installation

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09) 13

expansion vessel (B) must be fitted as close as possible to the

appliance in the central heating return.

• Pressurise the extra expansion vessel (B) to the same figure as the

expansion vessel (A) built into the appliance.

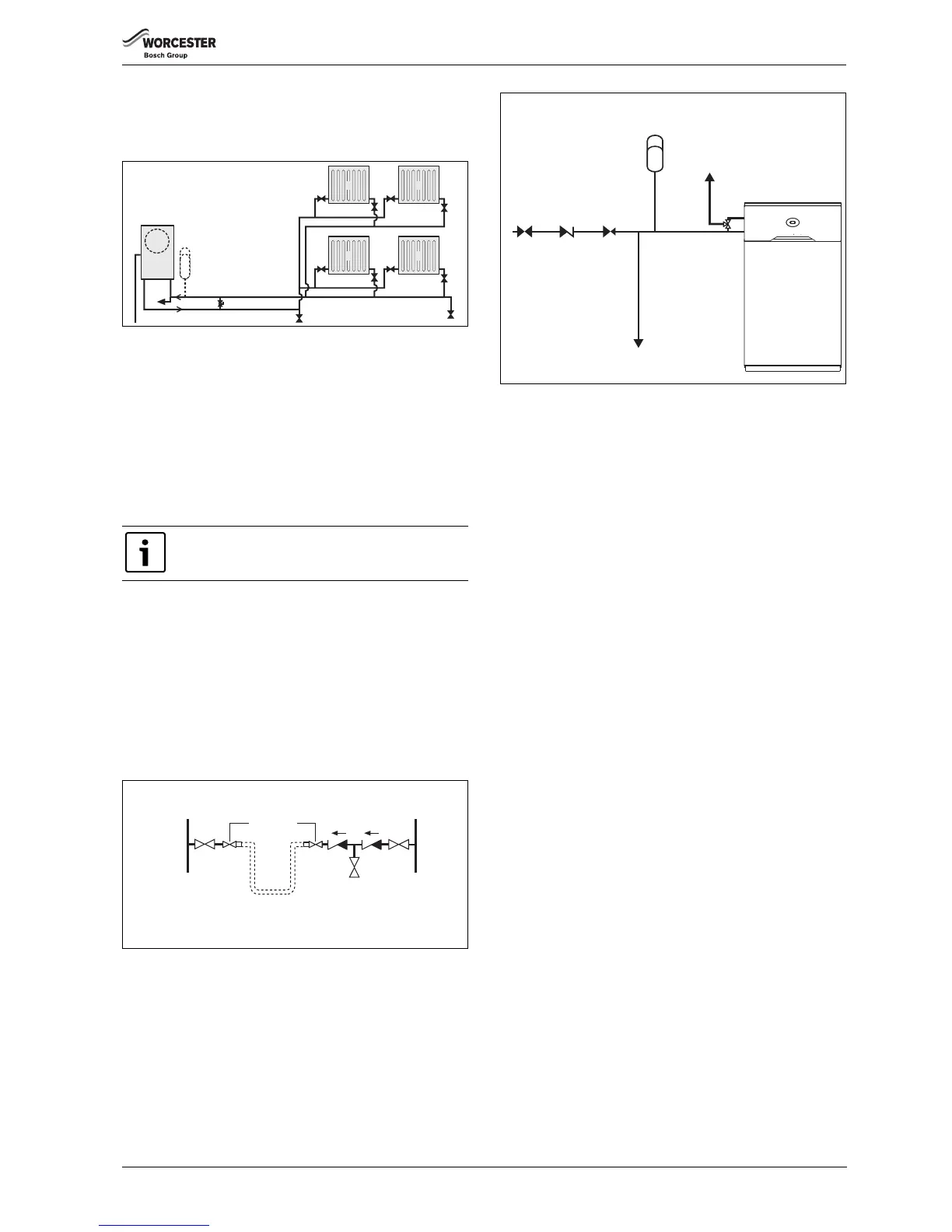

Fig. 8 Regular boiler, open vent system layout

[A] Expansion vessel*

[B] Extra expansion vessel

[C] Automatic bypass valve

[D] Drain cock

[E] Appliance

[L] Lockshield valve

[R] Radiators

[T] Thermostatic radiator valve TRV

[U] To filling system

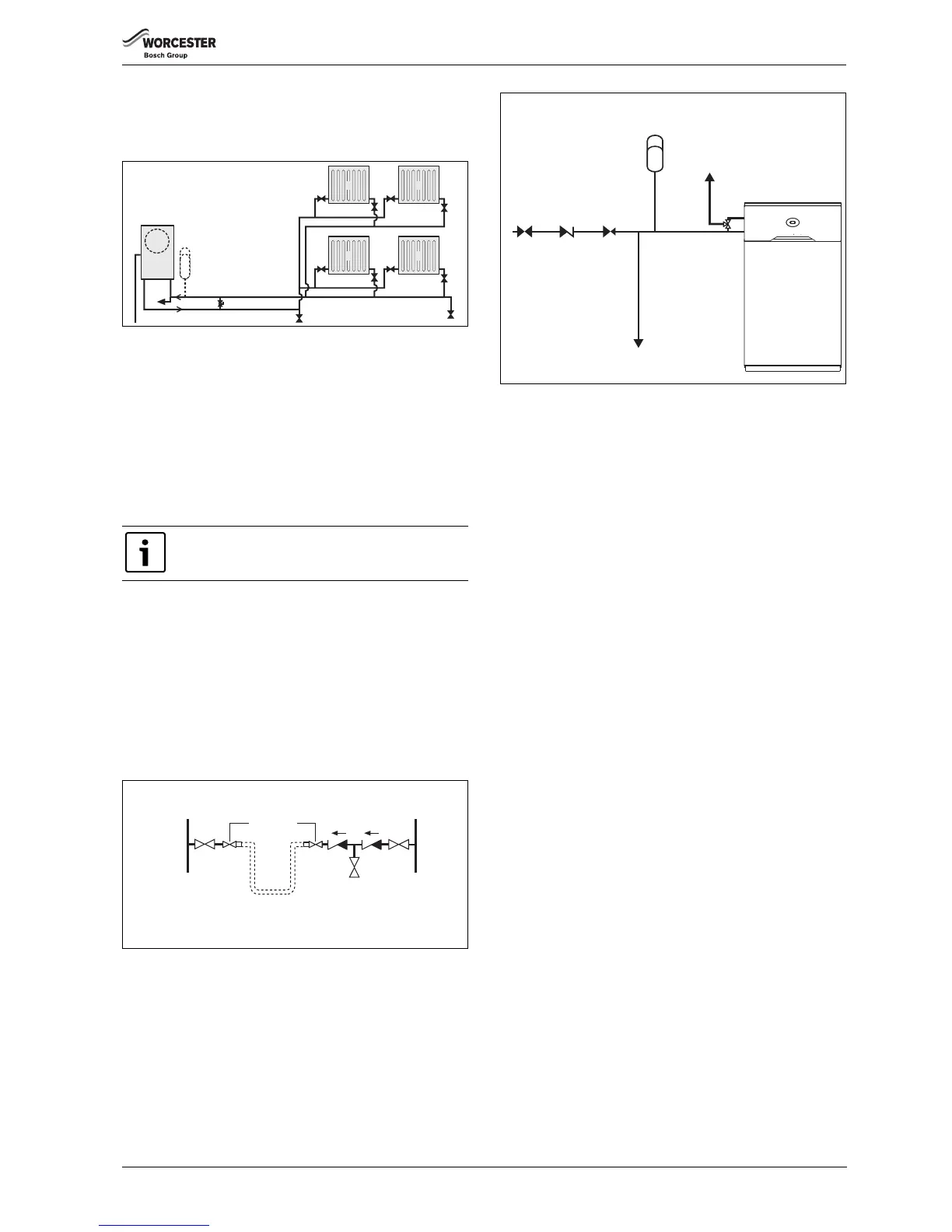

Filling primary sealed systems

• Where the system volume is more than 180 litres at 0.5 bar or

exceeds 2.65 bar at maximum heating temperature an extra

expansion vessel [B] must be fitted as close as possible to the

appliance in the central heating return.

• Pressurise the extra expansion vessel [B] to the same figure as the

expansion vessel built into the appliance.

• Filling the system must comply with the method shown in the figure

below.

• The filling point must be at low level and must never be a permanent

connection to the mains water supply.

• Filling loops must be WRAS approved.

Fig. 9

Fig. 10

Showers/Bidets:

• If a shower head can be immersed in water or comes closer than

25mm from the top edge of a bath or shower tray spill over level then

an anti-siphon device must be fitted to the shower hose.

Only thermostatically controlled showers are suitable for use with

this appliance.

• Bidets with direct hot & cold mains water can be used (with the

approval of the local water authority) and must be the over rim

flushing type with shrouded outlets to prevent the fitting of hand held

sprays.

Domestic hot water:

Plastic pipework

• Any plastic pipework used for the DHW system must have a

polymeric barrier, complying with BS 7921 and installed to BS 5955

with 1000mm (minimum) length of copper or stainless steel pipe

connected to the boiler.

• Before installing plastic pipework, the pipe manufacturer’s literature

should be consulted.

• To prevent the temperature & pressure exceeding the limits advised

by the pipe manufacturer, a pressure reducing valve must be used to

prevent the incoming water pressure exceeding 3 bar (maximum).

Also a mini expansion vessel must be fitted to absorb the expanding

water and a blending valve set to 60°C must be fitted before the DHW

plastic pipework.

• When selecting plastic pipework for use with domestic water supply,

it should be ensured that it is compliant with all current local &

national legislation & regulations, including building regulations part

G, BS 7291 - 1,2 & 3: 2006, BS 8000 - 15-15: 1990 and

information.

General:

• Taps and mixing valves must be capable of sustaining a pressure up

to 10 bar in accordance with the Water Regulations as they will be

operating at mains water pressure.

• Hot water temperature and flow rate are affected by the size and

insulation of pipework making up the distribution system and are

controlled by the hot water tap and the water main inlet pressure. A

mixing valve can be fitted if a more permanent setting is required.

• If using more than one outlet at once causes water flow starvation, fit

flow balancing valves or Ball-O-Fix valves to the appropriate outlets.

Filling the system

▶ The system must not be filled with artificially

softened water.

Loading...

Loading...