Fault finding and diagnosis

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09)46

8 Fault finding and diagnosis

8.1 Status cause codes

These cause codes are displayed during the normal operation of the

boiler. They are not faults, they just give information on the current

status of the boiler in real time.

During normal operation various status codes can be displayed by

pressing the service button.

The first screen of the information menu displays the current status

code, this will change as the boiler runs through the various modes and

sequences.

8.2 Information menu

Selecting the Information Menu

The Information Menu is a “read only” menu. Information about the boiler

is displayed here, some of the values are updated in real time to give the

current status of the boiler.

All menus time-out after 2 minutes and the display returns to the

normal operation display, the display backlight turns off after another

30 seconds and goes into stand-by mode.

Double up or down arrows indicate that the menu can only be scrolled up

or down, an up arrow combination indicates position in the menu where

options can be scrolled either up or down.

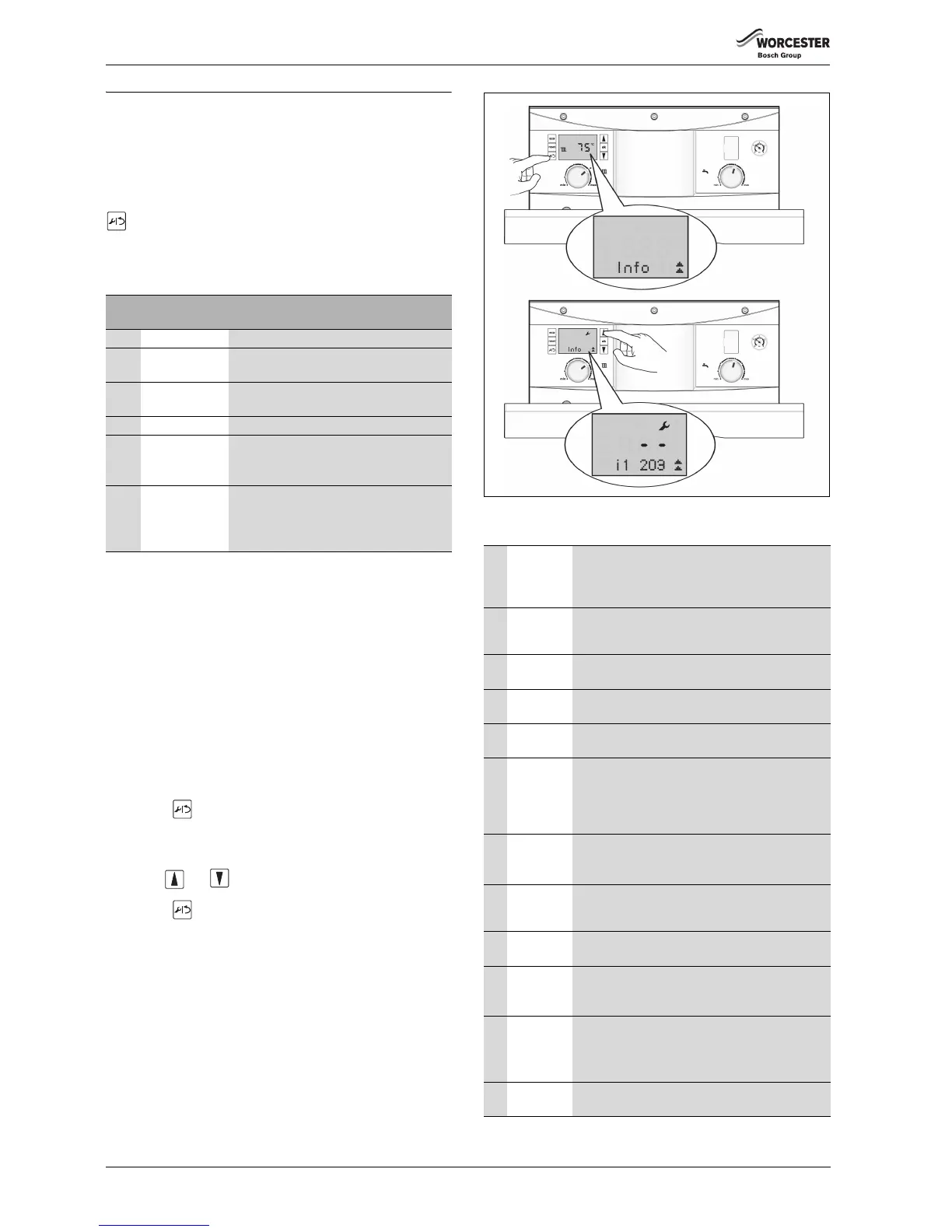

To enter the Information Menu

1. Press the button to enter the Information Menu.

– A 3 figure boiler status code will be displayed alongside the

Information Menu number. Refer to page 34 for a description of

the boiler status codes.

2. Use the and arrow buttons to scroll through the menu

items.

3. Press the button again to exit the Information Menu.

Fig. 83

Information Menu listing

Cause

code

200 CH active The Central Heating system is being heated.

201 DHW active The Domestic Hot Water is being heated/

tank is being heated.

202 CH Anti rapid-

cycle mode

Time delay to prevent rapid-cycling of the

boiler on the room thermostat.

203 System stand-by The boiler has no CH or DHW demands.

270 Power up mode The boiler is ON, warming up and running self

check routines. This lasts approximately

35 seconds.

358 Three way valve

anti-seize

Anti-seize operation. If the diverter valve has

not moved in 24 hours, the valve is operated

to prevent seizing, duration approximately

10 seconds.

Table 13

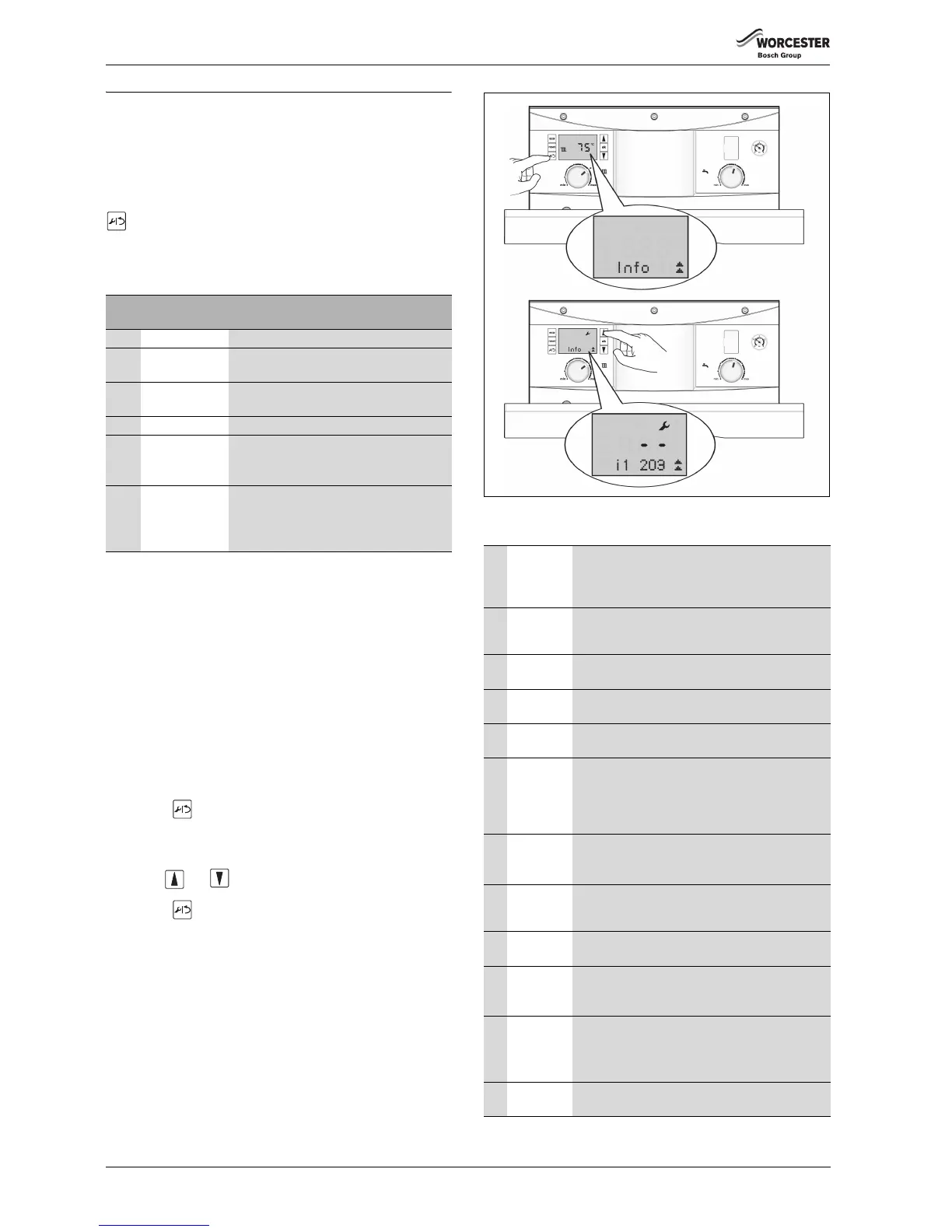

i1 Current

status

Every operation and mode of the boiler has a related

boiler status code.

The boiler status code is displayed on the screen as

a three figure number.

i2 Last error This can be viewed during normal operation.

Displays the last diagnostic code with boiler status

code.

i3 Maximum

CH output

The maximum possible CH output is displayed in

kW.

i4 Maximum

DHW output

The maximum possible DHW output is displayed in

kW.

i6 DHW flow

rate

The screen displays the current DHW flow rate in

0.1 l/m units.

i7 CH flow

temperature

set point

This is the temperature set point for the primary

flow from the main heat exchanger. This will be zero

during CH demand. Shows the heating control knob

set point unless weather compensation is activated

when it is the calculated set point.

i9 Flow

temperature

This is the flow temperature from the primary heat

exchanger displayed in real time (rounded to 0.5°C

units).

i10 Maximal

temperature

This is the current temperature from the maximum

safety sensor displayed in real time (rounded to

0.5°C units).

i11 DHW flow

temperature

Current DHW flow temperature displayed in real

time (rounded to 0.5°C units).

i12 DHW

temperature

set point

This is the thermal store set point temperature,

selected via the Hot Water control knob on the

fascia.

i13 Thermal

store

current

temperature

This is the thermal store current temperature,

displayed in real time (rounded to 0.5°C units).

i14 DCW inlet

temperature

Current DCW inlet temperature, displayed in real

time (rounded to 0.5°C units).

Table 14

Loading...

Loading...